How Plastic Toys Are Made

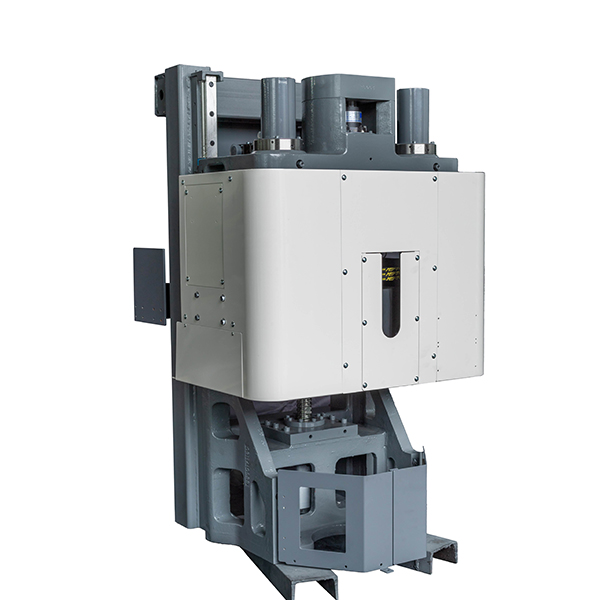

Vertical Injection Molding Machine for Plastic Toys and Containers Companies, which produce all sorts of plastic stuff use this machine. Major manufacturers include Arburg, Engel, Sumitomo and KraussMaffei. If you will, he can make plastic chips or large containers

The Best Machine Makers

A great firm making these machines generate types that will be effective and make dependable plastic areas in a rapidly turn around. Liquid plastic is forced into a mold by the machine, and the liquid cools to form of the shape of that particular mold. Then the last piece is removed from machine.

What Makes a Good Machine

A great machine is one that is reliable, efficient and accurate in all its functions. It is made with precision so that if it ever produced a plastic part, the part would be identical each time instead. They are simple to use and maintain, can be maintained for many years.

These top machine manufacturers provide full support to their clients. They can help in all aspects related to making plastic parts, right from design till the machine. To help customers select the right machine, they provide training and support to carry out effective use.

Squeeze the maximum out of your machine

In order to get the most out of your machine it must be properly maintained and used correctly. Of course, it is also important to train your employees in the safe use of a drone as well. The right machine and the right training can enable you to create nearly flawless plastic parts in no time.

You need vertical injection molding machine manufacturers to produce plastic parts. Top companies create great machines that work well - with strong support for the customer. Best machine makers enable you to make the manufacture of plastic parts very effectively.

Plastic toys and containers are made using an appropriate machine called a vertical injection molding.perm This machine is used by several companies that are dealing with the manufacture of different types of plastic products. Arburg, Engel Sumitomo and KraussMaffei are some of the prominent names to be counted among these manufacturers. This same Gewerbe has the ability to manufacture small parts as well as big plastic containers.

The best machine manufacturing companies focus on producing high performance machines designed to work efficiently and quickly while yet consistently creating perfect plastic parts through the precision of its separation process. Here, a mold is filled with liquid plastic that hardens into the appropriate form when cooled. Finally, the completed piece is then removed from the machinery.

The the hallmarks of a good machine

A Good machine is the one that delivers on all these 3 parameters. They are precision-engineered machines which delivers consistent quality in every plastic part they produce. They are also developed to be as user-friendly and durable, promising extended use.

Along with Additional Customer Assistance

Leading machine manufacturers not only provide customer with full support to take trough every step of plastic part production process from initial design through installation, adjustment until the end of running theat machines. Which help the customer in selecting a machine that is best for them, training programs and overall annual support to use it at its maximum efficiency.

Fine-Tuning The Work Of Machine

To harness the full capabilities of your vending machine, maintenance and use should be given priority. You need your team members to know the safe and proper way to use machine tools. With the right machine and proper training, you can efficiently manufacture high-quality plastic parts.

Maintaining requirements set by these vertical injection molding machine manufacturers is critical when it comes to producing plastic components which are widely used everywhere. The best companies manufacture robust and efficient machinery, providing their customers with unrivaled assistance. Partnering with the best machine manufacturers can help you in efficiently boosting high-quality plastic parts.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a vertical injection molding machine manufacturers you've been searching for. We are a partner which delivers opportunities.

Our customer services focuses your satisfaction. We've been providing the machining services and vertical injection molding machine manufacturers with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.

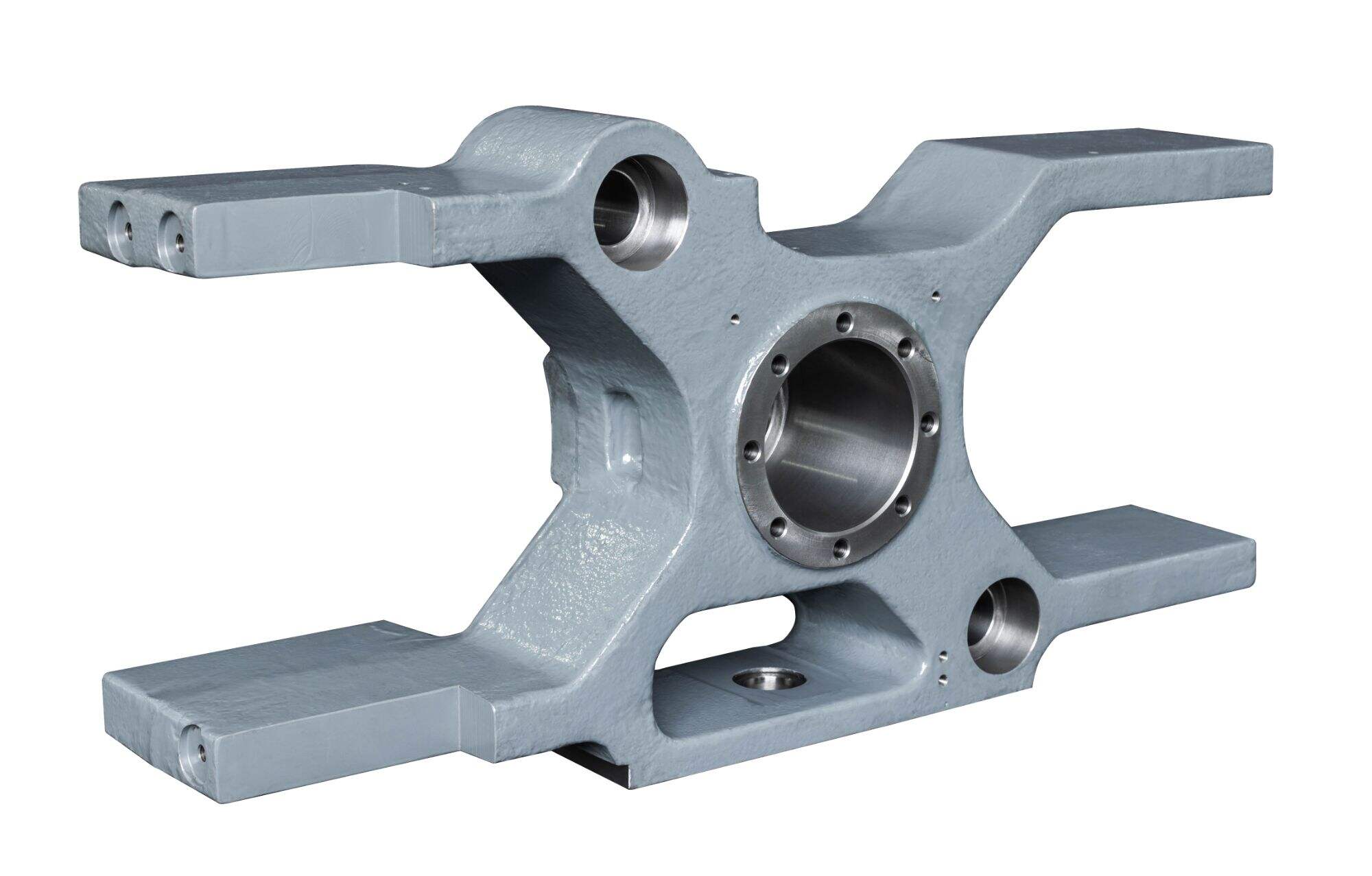

Pingcheng has at vertical injection molding machine manufacturers and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

With decades of experience and comprehension of this industry, Pingcheng is dedicated to providing its customers with a fair price. Once we have received a the request for quote, we vertical injection molding machine manufacturers in our specialized software right away, and then provide the best solution for your cost.