نحن واحدة من شركات تصنيع صب المعادن تحت الضغط العالي. هل ترغب في معرفة ما الذي تفعله هذه المصانع؟ إنها مصانع فريدة حيث يتم إنتاج الأجزاء المعدنية لأغراض مختلفة تشمل التروس والعجلات وحتى المحركات! لديهم دور كبير في إنشاء الأشياء التي نستخدمها يوميًا.

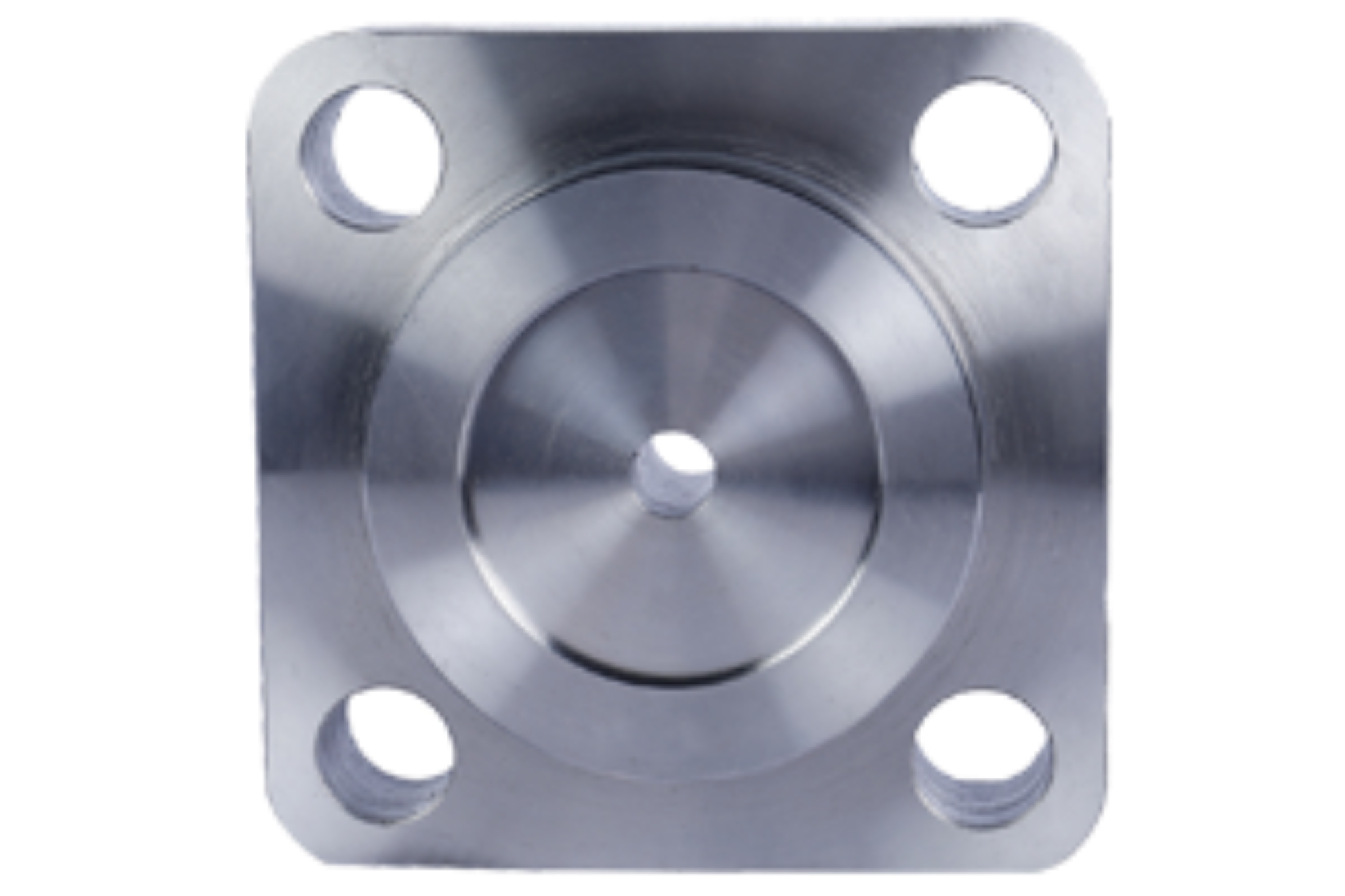

هل سبق وأن تساءلت عن كيفية إدارة مصنعي صب الضغط العالي إنتاج أجزاء معدنية ذات مقاومة عالية ومع ذلك دقيقة؟ considered عملية التشكيل بالحقن عملية مهمة لا ينبغي تجاهلها. الجزء الخاص من التصنيع حيث يتم دفع المعدن المنصهر بقوة داخل القالب لإنتاج نسخة دقيقة موجود هنا. القالب يجعل المعدن في حاوية فريدة من نوعها ستبقى كذلك حتى يبرد ويتماسك. كما يستخدم طريقة أخرى تسمى الصب بالمذابن الساخنة. هذه التقنية تتضمن آلة فريدة تحتوي على جهاز يحتوي على معدن ساخن. يتم استخدام مكبس لدفع المعدن إلى القالب، ويمكن مقارنة هذا بوجود ذراع بيونيكية يمكنها رفع الأشياء. بمجرد أن يتماسك المعدن، يكون لدينا جزء مصنع مستعد للعمل.

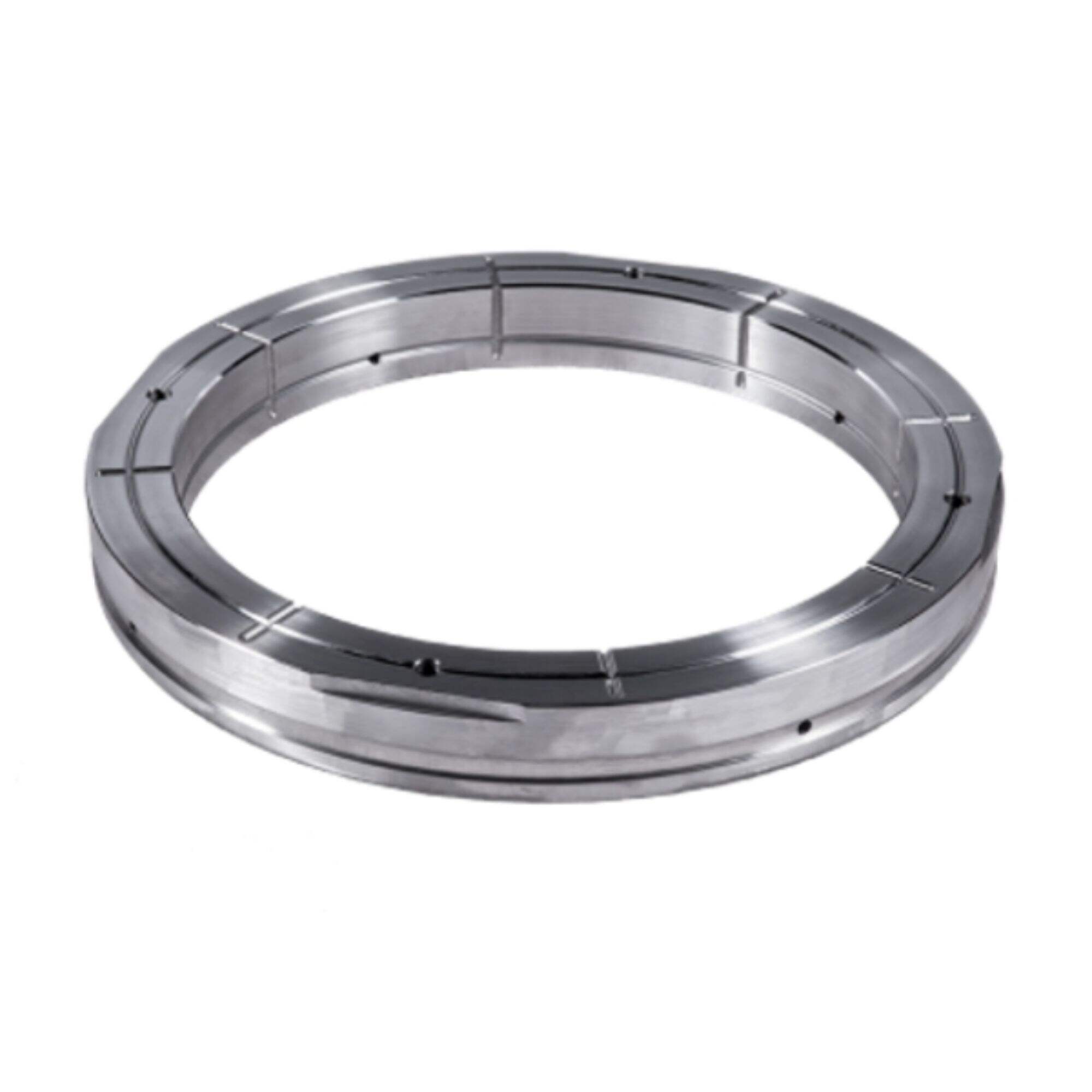

يفضل مصنعو صب المعادن تحت الضغط العالي استخدام المواد الأفضل لإنشاء أجزاء معدنية قوية وعالية الجودة. يعتبر الألمنيوم من أكثر المواد شيوعًا التي يستخدمونها. فهو قوي ولكنه خفيف الوزن (على سبيل المثال، لا يزن الكثير). يمكن تشكيله بسهولة إلى أي هيكل. غالبًا ما تكون المواد الشهيرة معادن أخرى مثل الزنك، النحاس أو المغنيسيوم. لكل من هذه المواد خصائص فريدة تمنحها ميزة لبعض أنواع الأجزاء. على سبيل المثال، الزنك هو عامل مضاد للميكروبات معروف يقاوم التآكل ولا يصدأ. هذا يمكّن من تصنيع أجزاء متينة للغاية.

بعض الأشياء الرائعة التي يمكن للشركات المصنعة لصب المعادن تحت الضغط العالي القيام بها! هذا يمكّنهم من تصنيع قطع دقيقة للغاية، مما يعني ببساطة أن بإمكانك إنشاء مكونات تتناسب بشكل شبه كامل. يمكنهم قياس المواد بمقدار صغير جدًا، أقل من حبة رمل! مثل هذه الدقة ضرورية للأجزاء التي يجب أن تتصل بأجزاء عاملة أخرى مثل التروس في الآلات. يمكنهم تصنيع أجزاء ذات هياكل معقدة، مثل التروس التي تحتوي على أسنان متطابقة بدقة. عند الحديث عن آلاف القطع التي تحتاج إلى التصنيع بسرعة، يمكن لهذه الشركات تنفيذ ذلك بطريقة فعالة وكفؤة زمنيًا، وهو أمر ضروري للوظائف التي تحتاج إلى أكثر من شركة واحدة لتصنيعها. يساعدون في الحفاظ على تشغيل المصانع بسلاسة من خلال إنتاج الأجزاء بسرعة.

تُعرف شركات صب المعادن تحت الضغط العالي بخبرتها في إنتاج قطع معدنية، مما يكسب ثقة الشركات. لدى الصانعين خبرة واسعة في تصنيع أنواع مختلفة من الأجزاء التي تكون قوية ودقيقة للغاية لتلبية احتياجات أي صناعة. هذا يساعد أيضًا الشركات التي تواجه طلبات مرتفعة على إنتاج الأجزاء بسرعة. بالإضافة إلى ذلك، فإن المعرفة باستخدامهم معدات ومواد عالية الجودة فقط تجعل الشركات تعلم أنه عند استخدام خدمات United Gear P&H Parts & Services، لن تكون أجزاؤها قوية بما يكفي لأي عمل فحسب، بل ستستمر لفترة أطول أو بنفس المدة قبل أن تتكسر.

تلتزم شركة بينغتشنغ بمساعدة العملاء على تحقيق أهدافهم التجارية من خلال شركات تصنيع الصب تحت الضغط العالي وحلول الخدمات التي نقدّمها. وتركّز شركتنا على مساعدتك في إطالة عمر خطوط إنتاجك وزيادة قيمتها. وشركة بينغتشنغ هي الشركة المصنِّعة الموثوقة التي تبحث عنها. فنحن شركةٌ تقدّم خياراتٍ متنوعة.

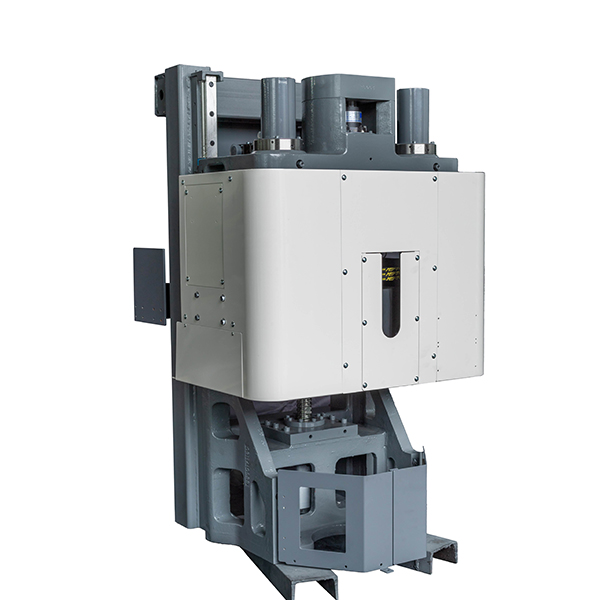

وتضمّ شركة بينغتشنغ حاليًّا أكثر من ٢٠ جهاز تصنيع وأكثر من ٥٠ موظفًا فنيًّا مؤهلًا. وهي شركاتٌ مصنِّعةٌ للصب تحت الضغط العالي. وبعد ذلك، تُفحص المنتجات باستخدام أدوات القياس من علامة «ميتسوتويو» وأجهزة قياس الإحداثيات ثلاثية الأبعاد (CMM)، والتي تُعاير بشكل دوري. وتضمن عملية التحقّق المزدوج أن تكون جودة منتجاتنا دقيقةً ومستقرةً. ويمكن تتبع كل مكوّنٍ ومراقبته بدقة أثناء عمليات التشغيل الآلي والتركيب.

استنادًا إلى خبرة مصنّعي الصب الدقيق عالي الضغط ومعرفتهم بالقطاع، تلتزم شركة بينغتشنغ بتقديم أسعارٍ صادقة للعملاء. فنحن نحلّل الرسومات الفنية، ونعيد إنشائها باستخدام برامج متخصصة، ثم نقدّم أفضل سعر ممكن.

بينغتشنغ هي شركة مُصنِّعة متكاملة الخدمات للصب الدقيق عالي الضغط. وشحن منتجاتنا ليس سوى بداية لشراكتنا معكم. وتتمحور خدمة العملاء لدينا حول ضمان رضاكم التام. وعلى امتداد أكثر من ٢٠ عامًا، قدّمنا خدمات التصنيع وبنينا شراكات تعاون وثيقة مع شركات يابانية معروفة عالميًّا. وتعتمد التزامات بينغتشنغ بالأسعار الصادقة على خبرتها العميقة الممتدة على مدى عقود في هذا القطاع، وعلى فهمها العميق له. فبعد استلام طلب اقتباس، نقوم بتحليل الرسومات الفنية باستخدام برامج متخصصة، ونقدّم الحل الأمثل بتكلفة معقولة.