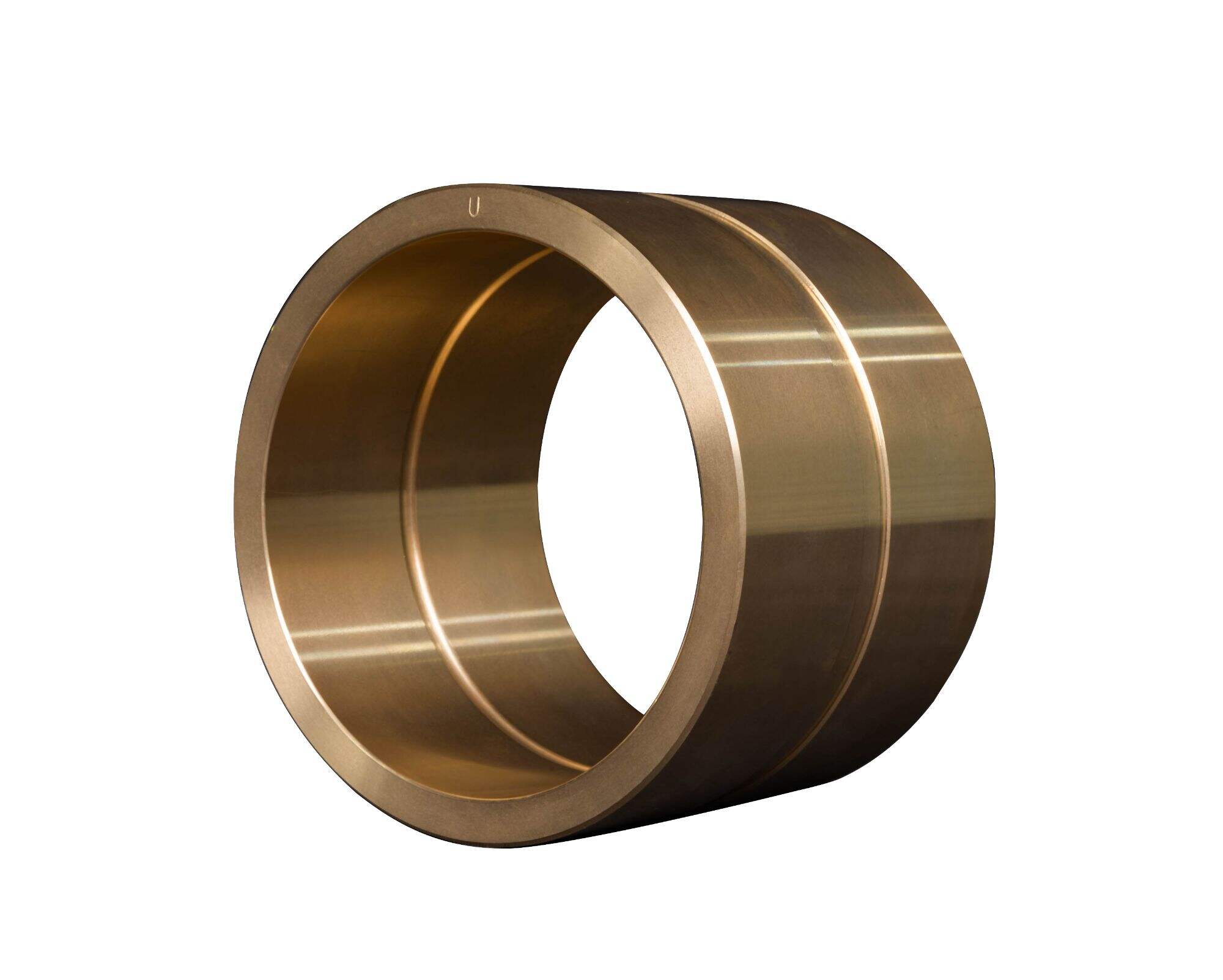

في المضخات، يعتبر غلاف محامل المضخة جزءًا مهمًا ويؤدي وظيفة داعمة لتشغيل المضخة. هذا هو الغلاف الذي يحتوي على المحامل التي تعمل من خلاله لتمكين تدفق السوائل لفترة طويلة. سيكون من الصعب تشغيل المضخة إذا تم إزالة هذه المحامل.

يجب تذكر أن هناك أنواع مختلفة من أغلفة دعم المضخة المستخدمة لأغراض مختلفة. هناك الأغلفة القوية جدًا والمصنوعة من المعدن، بينما تتكون الأخرى فقط من البلاستيك المرنة. نوع المضخة واستخدامها يحدد اختيار مادة الغلاف.

مصممة الإسكان لحماية الدب|array من التلف وضمان تزييتهم بشكل جيد حتى لا ينفد مفعولهم مبكرًا. للتأكد من عمل المضخة بشكل صحيح، يجب عليك الحفاظ على إسكانها بانتظام. من المهم اتباع توصيات الصيانة التي تقدمها شركة تصنيع المضخة.

اختيار الإسكان المناسب وكيفية تركيبه

كل هذه عوامل رئيسية تتعلق بوظائف المضخة الصحيحة وتعتمد بشكل أساسي على اختيار وتركيب الإسكان المناسب. يمكن أن يؤدي اختيار غير صحيح للإسكان إلى فشل المضخة مبكرًا بسبب الدعم غير الكافي أو عدم التحالف أو التزييت غير الكافي. يعتبر التركيب الجيد مهمًا لحياة مضختك وإسكانها.

مشاكل تشغيل المضخة: يمكن أن تواجه مشاكل خطيرة في تشغيل مضختك نتيجة أي صعوبات تحدث في الغطاء. وهذا يشير إلى وجود مشاكل كبيرة في الجهاز إذا كنت تواجه أعراض مثل: ضوضاء مفرطة، اهتزاز، ارتفاع درجة الحرارة أو تسريب. من الأفضل فحص الدب|array وتبديل الزيت أولاً. إذا استمرت المشكلة، سيتعين عليهم فحص وإصلاح غطاء المضخة.

تصميم غطاء دبابة المضخة عبر القفزات التكنولوجية الحديثة. تم تصميم أغطية اليوم لتكون ذاتية التشحيم ولا تتطلب أي صيانة منتظمة. وأخيرًا، يتم تصنيع بعض الأغطية من مواد مركبة توفر طبقة إضافية من القوة والتحمل. وهذا بدوره يساعد على جعل المضخات أكثر كفاءة بينما يقلل من تكاليف الصيانة.

لإيجاز القول، يبدو أن غلاف محامل المضخة عبارة طويلة ولكنها مهمة لعمل أي مضخة. فهم كيفية اختيار النوع المناسب، تركيبه وصيانته يمكن أن يعمل عجائب في تمديد العمر الافتراضي وتحسين الأداء أيضًا. لقد تطور غلاف المضخة مع اندماج التكنولوجيا المتقدمة والتطورات بشكل كبير، مما جعل المضخات أكثر موثوقية وأقل تكلفة للصيانة. لذلك، المرة القادمة التي ترى فيها مضخة تعمل بحالة جيدة... فكر فيما هو داخلها يجعل استخدامها سلسًا قدر الإمكان.

يقوم Pingcheng بتأسيس غلاف دعم مضخته على عقود من الخبرة الصناعية وفهم عميق. بعد تلقي طلبات العروض، نفحص الرسم ونقوم بالمحاكاة في برنامج متخصص فورًا، ثم نقدم الحل الأكثر فعالية بسعر عادل.

تلتزم شركة بينغتشنغ بمساعدة عملائها على تحقيق أهدافهم التجارية من خلال حلول سلسلة التوريد والخدمات التي نقدمها بأنفسنا. ونركّز على المساعدة في إطالة عمر غلاف محامل المضخات الخاصة بمنتجاتكم. وشركة بينغتشنغ هي مصنّعٌ موثوقٌ به تبحثون عنه، وهي موردٌ موثوقٌ للفرص.

وتمتلك شركة بينغتشنغ حاليًّا أكثر من ٢٠ قطعة من معدات التصنيع وغلاف محامل المضخات. وتسعى الشركة إلى تقديم جودة عالية. وتتم معايرة أجهزة القياس من شركة ميتسوتويو وأجهزة قياس الإحداثيات (CMM) بشكل دوري. ويضمن هذا التحقق المزدوج أن تكون جودتنا موثوقة ودقيقة. كما أن جميع الأجزاء الرئيسية قابلة للتتبع والمراقبة أثناء عمليات التشغيل الآلي والتركيب.

بينغتشنغ شريكٌ شاملٌ في جميع مراحل العملية ودورة الحياة. إن شحن المنتجات هو مجرد بداية لشراكتنا معكم. وخدماتنا للعملاء تركز كل التركيز على ضمان رضاكم التام. ولقد قدّمنا، على مدى أكثر من 20 عامًا، خدمات الأدوات والماكينات وبنينا شراكات قوية مع شركات يابانية مرموقة. وتستند التزاماتنا بالشفافية في التسعير إلى خبرتنا الطويلة في هذا المجال ومحامل المضخات الخاصة بنا. ونقوم بمراجعة الرسومات باستخدام برامج متخصصة، ونقدّم أفضل الحلول بأقل التكاليف المعقولة فور استلام طلبات الاقتباس.