تساعد موردو ماكينات التشكيل الشركات الصغيرة على إنتاج منتجاتهم بطريقة فعالة باستخدام أجزاء صغيرة تُسمى القوالب. نسخ متخصصة من الآلات المدمجة، هذه هي أفضل آلات صناعة الأجزاء الصغيرة في النهاية الصغيرة. إنها الأفضل إذا كانت شركتك تتطلب تصنيعًا سريعًا وكفؤًا للمنتجات ذات الحجم الصغير.

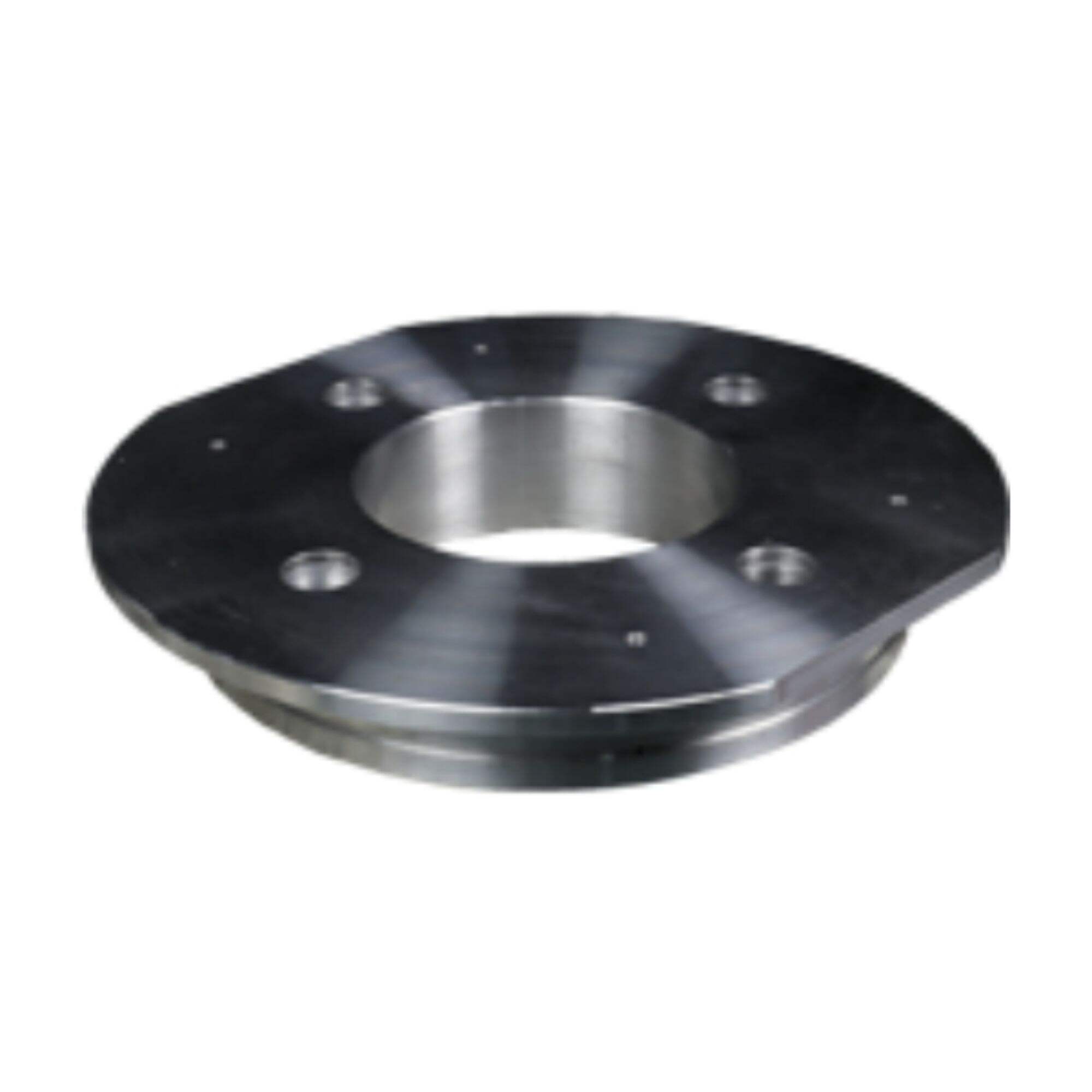

فوائد أخرى كبيرة لمachines التشكيل الصغيرة هي نسبة السعر إلى القدرة وفعالية التكلفة. نظرًا لأن هذه الأجهزة قادرة على إنتاج العديد من الأجزاء الصغيرة في نفس الوقت، فهي فعالة واقتصادية للشركات أيضًا. تتميز ماكينات التشكيل الصغيرة بالمرونة العالية ويمكنها تصنيع المنتجات من لعب الأطفال إلى أجزاء الآلات.

بالإضافة إلى ذلك، يمكن أن يحسن استخدام آلة تشكيل/صب صغيرة العملية بشكل كبير. كل واحدة من هذه الآلات مجهزة لتقديم أجزاء صغيرة وتفصيلية بسهولة. كما أنها تصنع نماذج أولية ممتازة لإثبات جودة الأجزاء قبل أن تقرر بدء الإنتاج الضخم.

ماكينات تشكيل صغيرة لشركات تبحث عن إعادة تنظيم خط إنتاجها، الاستثمار في ماكينات تشكيل صغيرة ذات جودة عالية هو أمر يغيّر القواعد. يمكن لهذه الأدوات بسرعة إنتاج عدد لا حصر له من القطع الصغيرة، مما يوفر تصنيعاً أسرع وأكثر كفاءة. توفر ماكينات التشكيل الصغيرة للشركات وسيلة لزيادة خيارات الإنتاج لديها، سواء كان ذلك شيئاً بسيطاً وصغير النطاق مثل الألعاب أو مكونات الآلات.

مزايا وجود ماكينة تشكيل مصغرة في العمليات: أولاً، تتيح لك إنشاء قطعة صغيرة جداً بحيث لا تستطيع الآلات الأخرى القيام بها بنفس الفعالية. وثانياً، تصبح واحدة من الخيارات الأرخص والأسرع للتصنيع. كما أنها تساعد في تحسين عملية التشكيل وتغيير كفاءتها. وفي النهاية، تصنع ماكينة التشكيل الصغيرة منتجات رائعة بشكل أسرع.

بالمجملة، تمتلك ماكينات التشكيل الصغيرة تأثيرًا كبيرًا على أي عمل يحتاج إلى استخدام الأجزاء الأصغر. وهذا لأن هذه الآلات ليست فعالة واقتصادية فقط، بل إنها تساعد أيضًا في تحسين عملية التشكيل لديك. عندما يتعلق الأمر بالشركات الصغيرة التي تحتاج إلى حلول تصنيع دقيقة، فإن السرعة التي يتم بها تطوير الأجزاء الجديدة لا مثيل لها وتتم ثورة خطوط الإنتاج باستخدام هذه الآلات الصغيرة للتشكيل. إذا كنت تمتلك شركة صغيرة تعتمد على إنتاج الأجزاء الصغيرة، فإن الاستثمار في ماكينة تشكيل صغيرة قد يكون ضروريًا لزيادة الإنتاجية وتحسين جودة المنتج.

تركّز خدماتنا للعملاء على رضاكم. وعلى امتداد عقدٍ من الزمن، قدّمنا خدمات التشغيل الآلي وآلات التشكيل الصغيرة بالتعاون مع شركات يابانية معروفة. ويستند التزام شركة بينغتشنغ بالأسعار الشفافة إلى خبرتها الطويلة في المجال ومعرفتها العميقة بالقطاع. ونحن نحلّل الرسومات باستخدام برامج تحليل متخصصة، ونقدّم أفضل الحلول بأسعار معقولة بمجرد استلامنا طلبًا للاستعلام عن الأسعار.

تلتزم شركة بينغتشنغ بمساعدة العملاء على تحقيق أهدافهم التجارية من خلال آلات التشكيل الصغيرة والحلول الخدمية التي نقدّمها. وتركّز شركتنا على مساعدتكم في إطالة عمر خطوط إنتاجكم وزيادة قيمتها. وشركة بينغتشنغ هي المصنّع الموثوق الذي تبحثون عنه. ونحن شركةٌ تقدّم خياراتٍ متنوعة.

تستند آلة صب بيتشنغ الصغيرة إلى عقود من الخبرة في المجال والفهم العميق له. فنحن نراجع الرسومات، ونُنشئ النموذج باستخدام برامج متخصصة، ثم نقدّم أكثر الأسعار تنافسية.

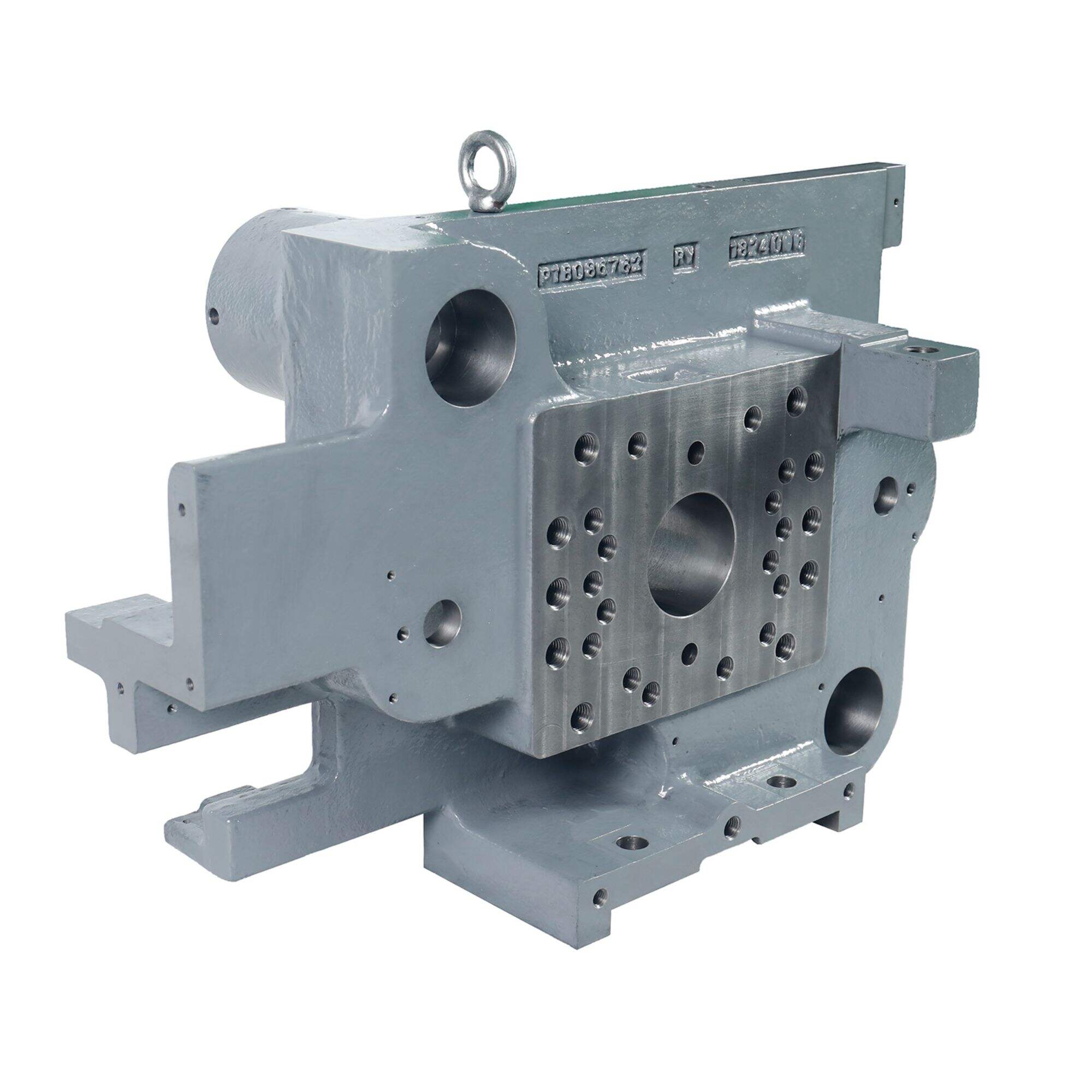

وتمتلك شركة بيتشنغ الآن أكثر من ٢٠ جهاز تصنيع وآلة صب صغيرة، مع سنوات عديدة من الخبرة. وتهدف الشركة إلى تقديم جودة عالية. وبعد ذلك، تُفَحِّص الشركة المنتجات باستخدام أدوات القياس من شركة ميتسوتويو وأجهزة قياس الإحداثيات (CMM) التي تُعايَر بشكل دوري. ويضمن التحقق المزدوج دقة الجودة واستقرارها. كما يمكن تتبع كل مكوّن رئيسي والتحكم فيه أثناء عمليات التشغيل الآلي والتجميع.