يتكون توربين الرياح من مجموعة متنوعة من الأجزاء - ومن بين جميع هذه المكونات، يجب التركيز على صندوق التروس الخاص بالتوربين. هذا هو الجهاز المسؤول عن تحويل طاقة الرياح إلى شكل يمكننا استخدامه من خلال تحويلها إلى كهرباء. فإذا لم يعمل صندوق التروس بكفاءة أو فشل، فهذا يعني أن توربين الرياح لن يتمكن من العمل بشكل صحيح. ثم ينقل التوربين القوة إلى صندوق التروس الذي يجعل الشفرات الكبيرة تدور بسرعة أكبر - وذلك لأن صندوق التروس يتحكم في مدى سرعة دوران شفرات التوربين. يمكن لصندوق التروس أن يتلف أو يفشل، مما يؤدي إلى دورة الشفرات بسرعة كبيرة جدًا، وقد تتوقف تمامًا عن الدوران. وهذا يمكن أن يؤدي إلى أضرار بالغة للتوربين أو حتى تعطيله. يجب أن يكون صندوق التروس موثوقًا به لتمكين توربين الرياح من إنتاج الطاقة بطريقة فعالة وآمنة للغاية.

بالنسبة لمراوح الرياح، فإن صندوق التروس هو عنصر رئيسي يحدد ما إذا كانت تعمل بشكل جيد أم لا. تصميم صندوق التروس وواحد من أهم العوامل التي يجب أخذها في الاعتبار هو عدد التروس التي سيحتويها داخله. المزيد من التروس تعطي صندوق التروس تحكمًا دقيقًا أكبر في سرعة دوران الشفرات. بهذه الطريقة، يمكن للمحرك الهوائي أن يؤدي عمله بشكل صحيح حتى عند وجود بعض التقلبات في سرعة الرياح. إذا زادت قوة الرياح أو حدثت نَفَحات، على سبيل المثال، وتدور شفراته بسرعة في لحظة غير مناسبة، يمكن لصندوق التروس تعديل سرعة دوران الشفرات مثل مراوح طائرات R/C الجديدة # – حتى لو كانت صغيرة - للتأكد من استمرار عمل كل شيء بشكل صحيح. اختيار المواد التي تُصنع منها التروس هو أيضًا جانب مهم. المادة القوية ذات الجودة العالية - مثل التروس المصنوعة من الفولاذ أو المعادن الصلبة الأخرى - يمكن أن تساعد في زيادة عمرها الافتراضي، وليس فقط ذلك، بل إنها تساعد أيضًا في توفير المال بسبب تقليل تكاليف الإصلاح والاستبدال لاحقًا.

بعد ذلك بفترة وجيزة، تحتاج صندوق التروس الخاص بالتربين إلى صيانة منتظمة ليعمل بشكل جيد. تأكد من أنك تقوم بصيانتها بانتظام عن طريق فحص مستويات التآكل والزيت على التوالي. من الضروري للغاية التأكد من وجود كمية كافية من الزيت لضمان التشغيل الصحيح. إذا أظهرت الأجزاء أي علامة على الضرر، يجب إصلاحها أو استبدالها فورًا. الاهتمام بصندوق التروس يمكن أن يوفر عليك إصلاحات أكثر تكلفة. وعلى الرغم من الصيانة المجدولة، فإن جانبًا مهمًا آخر هو أن أي مشكلة في صندوق التروس يجب إصلاحها بمجرد اكتشافها. إذا تم ترك المشكلات دون معالجة لفترة طويلة، فقد تسبب المزيد من الأضرار، مما قد يؤدي في النهاية إلى الحاجة لاستبدال كامل لصندوق التروس - وهو أمر أكثر تكلفة ليس فقط من حيث المال ولكن أيضًا من حيث المدة التي ستكون فيها خارج الخدمة أو غير قادر على قيادة سيارتك.

تحتاج إلى التروس المناسبة في صندوق التروس لأن لها دورًا حاسمًا في توربينات الرياح. هذه المكونات تنقل الطاقة التي يولدُها دوار توربين الرياح إلى المولد الذي يقوم بتحويلها إلى كهرباء. تعمل التروس أيضًا كمخفض سرعة، مما يبطئ من سرعة الشفرات إلى مستويات آمنة ومثالية لإنتاج الطاقة. عندما تعمل التروس بشكل غير صحيح، سيؤثر ذلك على كل مرحلة من مراحل تحويل واستخدام الطاقة، وقد تنخفض كفاءة النظام بأكمله، بل قد يتسبب في تلف الجهاز بالكامل. وهذا هو السبب في أن الحفاظ على صيانة التروس والتحقق منها بانتظام أمر مهم.

تم تحقيق تطورات جديدة ومثيرة مؤخرًا في تقنية صندوق التروس الخاص بالتوربينات. مولدات المغناطيس الدائم مطبقة بشكل عملي، حيث لا حاجة لصندوق التروس لأن هذه المولدات تنتج الطاقة الميكانيكية بواسطة مغناطيسات قوية والتي تنتج الكهرباء في النهاية. هذا يعتبر ميزة كبيرة لأنه يسمح للتوربينات التي تستخدم مولدات المغناطيس الدائم بالعمل بكفاءة أكبر وتحتاج إلى صيانة أقل مقارنة بالنماذج التقليدية. تطور مثير آخر هو تقديم التوربينات الخالية من التروس. كلا نوعي التوربينات يستخدمان القيادة المباشرة وبالتالي لا يحتاجان إلى صندوق تروس. هذا التصميم يجعلها أكثر كفاءة من التوربينات ذات مولدات المغناطيس الدائم، مما يجعلها أسهل بالنسبة للمستخدمين من حيث الصيانة.

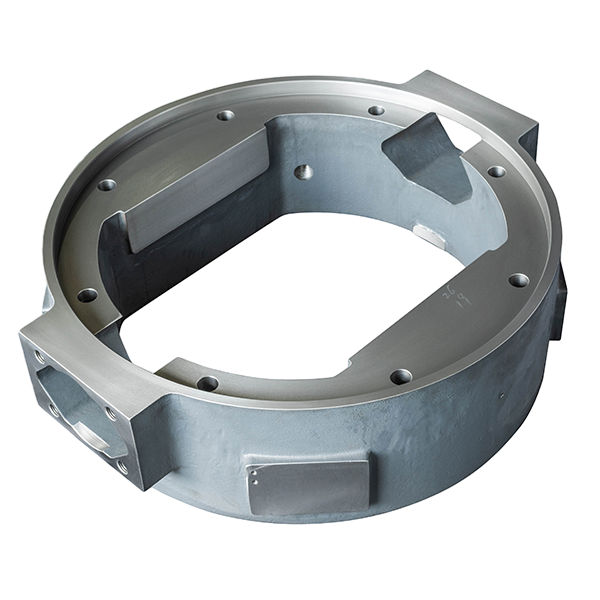

تلتزم شركة بينغتشنغ بمساعدة العملاء في مجال علب تروس التوربينات من خلال توفير حلول سلاسل التوريد والخدمات الخاصة بنا. ونسعى جاهدين لمساعدتكم على إطالة عمر منتجاتكم وتعظيم قيمتها. وشركة بينغتشنغ هي المصنِّع الموثوق الذي تبحثون عنه. فنحن شركةٌ تُحقِّق الإمكانات الكامنة.

يركز خدمة عملائنا على رضاكم. لقد قمنا بتقديم خدمات التصنيع وصناعة صندوق تروس التوربين بالتعاون مع شركات يابانية معروفة في الصناعة لأكثر من 20 عامًا. بناءً على سنوات من الخبرة والمعرفة بالصناعة، فإن بينغتشنغ مكرسة لتقديم سعر صادق لعملائنا. نقوم بتقييم الرسومات باستخدام برامج خاصة ونقدم أفضل الحلول بأقل التكاليف بمجرد استلام طلبات العروض.

وبفضل خبرتنا التي تمتد لسنواتٍ عديدة في مجال علب تروس التوربينات، تلتزم شركة بينغتشنغ بتقديم أسعارٍ صادقة للعملاء. وعند استلام طلب اقتباس، نقوم فورًا بمراجعة الرسومات ومحاكاتها باستخدام برامج متخصصة، ثم نقدّم الحلَّ الأمثل بسعرٍ عادل.

شركة بينغتشنغ لعلب التروس التوربينية لديها الآن ٥٠ موظفًا فنيًّا يتمتَّعون بسنواتٍ عديدة من الخبرة. وتهدف الشركة إلى تقديم منتجات عالية الجودة. وبعد ذلك، تُجرَى عمليات فحص المنتجات باستخدام أجهزة القياس من شركة ميتسوتويو وأجهزة قياس الإحداثيات ثلاثية الأبعاد (CMM)، التي تُ calibrated بشكل دوري. ويعمل التحقُّق المزدوج على ضمان دقة وثبات جودة المنتج. كما يخضع تصنيع وتركيب جميع الأجزاء المهمة للرصد والتعقُّب.