المعدات الخاصة يتطلب تشكيل الحقن معدات خاصة لإنشاء منتجات بلاستيكية ثلاثية الأبعاد. هذه المعدات تعامل مستوى الدعم المطلوب لجودة المنتج، مبتكرة وآمنة للتنفيذ. الآن، نظرة ثاقبة حول المعدات المستخدمة في تشكيل الحقن ودورها في الصنع.

فوائد آلة تشكيل الحقن

تتمتع الأجهزة المستخدمة في تقنية تشكيل الحقن بعدد من المزايا التي تجعلها شائعة لإنتاج كميات كبيرة من المنتجات البلاستيكية. أحد العلامات الحمراء لهذه الخدمة هو أنها تنتج كميات كبيرة ومنتجات ذات جودة عالية بدقة ودقة عالية. بالإضافة إلى ذلك، فإنه يسمح بعملية تصنيع صناعي سريع مع نتائج أسرع وكفاءة إجمالية أكبر. ومع عملية تركيب سهلة التفاهم، فإن خط الضغط يقدم عادة منتجات ذات جودة عالية بكميات كبيرة وبأسعار تنافسية، مما يجعله مغرًا للشركات التي تبحث عن تكلفة منخفضة.

تطوير آلات تشكيل الحقن

على مر السنين، تطورت معدات حقن القوالب وشهدت العديد من الابتكارات التي تم تصميمها لتحسين الأداء وجعلها أكثر كفاءة. تعتبر آلات التحكم العددي بواسطة الحاسوب (CNC) مثالاً بارزًا، حيث تجلب الدقة وتحمل الخطأ إلى التصنيع. بالإضافة إلى ذلك، ساهم إنشاء أنظمة أوتوماتيكية في تحسين السرعة وإضافة أمان في العمليات.

المزايا مع ماكينات حقن القالب هايبريد ماشين

السلامة دائمًا هي الاعتبار الأساسي لأي عملية تصنيع، وفي حقن القوالب لا تختلف الأمور. يتم تجهيز المعدات المستخدمة في هذه العملية بميزات أمان مختلفة لتجنب أي حوادث وحماية المشغلين. يتم تركيب مفاتيح الأمان لإيقاف الآلات عندما يكون هناك نقص في السلامة، بينما توفر المستشعرات والمؤشرات تحذيرات للمشغلين في حالة حدوث أعطال.

في خط مع أداة حقن القالب

من أجل تشغيل المعدات المستخدمة في إنتاج تشكيل بالحقن بشكل صحيح، يتطلب ذلك مستوى إضافيًا من المهارات والمعرفة. يجب أن ت familiarise نفسك مع الجوانب التشغيلية واتباع الإجراءات الأمنية الضرورية. يتطلب هذا العملية إدخال المادة الخام إلى آلة، ثم تسخين المادة لصهرها وأخيراً حقنها في قالب مغلق حيث يُسمح لها بالتبريد والتصلد قبل طردها من الأداة.

صيانة ومaintenance معدات تشكيل الحقن

الصيانة والخدمات المناسبة لمعدات تشكيل الحقن هي عوامل أساسية لتمديد دورة الحياة وتحقيق أفضل الأداء. تنظيف دوري، تزييت واستبدال الأجزاء المشهورة ضروريات يجب على المشغلين القيام بها. سيتم التعامل مع أي أعطال أو تعطل بسرعة بواسطة فنيين مدربين يمكنهم منع المزيد من الأضرار.

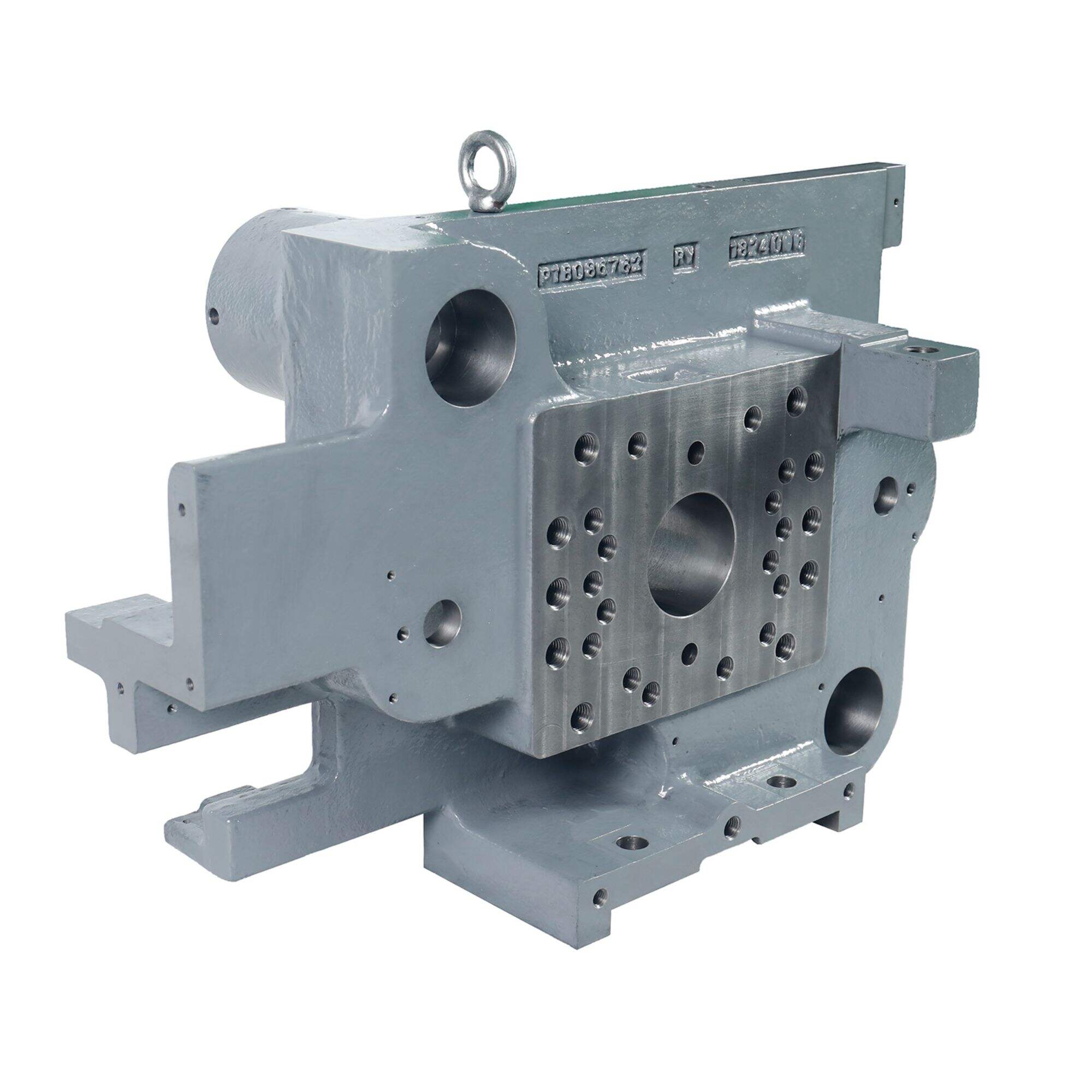

هيكل ماكينة تشكيل الحقن (جودة)

يعتمد جودة المنتج في تشكيل بالحقن بشكل أساسي على المعدات - الآلات، القوالب والمكونات الملحقة. تعتبر الآلات عالية الجودة استثمارًا يحقق عوائد على المدى الطويل، حيث تنتج فقط أفضل المنتجات لتلبية معايير الصناعة. وللتشكيل بالحقن تطبيقات مختلفة مثل إنتاج الحزم، قطع الغيار والملحقات للمركبات، الألعاب والعناصر الأخرى مثل المعدات الطبية أو الإلكترونيات.

الاستنتاج

تتطلب المنتجات البلاستيكية عالية الجودة أدوات وتجهيزات ذات جودة عالية، ويعد جزءًا مهمًا من ذلك معدات حقن القوالب. تستخدم العديد من الشركات هذا الحل بسبب المزايا التي يقدمها مثل الدقة والكفاءة والتحكم في التكلفة - وهي متطلبات أساسية عند الإنتاج بكميات كبيرة. أدى الابتكار في الصناعة إلى تحقيق مستويات أعلى من السلامة والكفاءة والدقة لجميع العمليات. لتحقيق الاستفادة القصوى، والعناية المناسبة، وتقديم صيانة كافية للمعدات، هو أمر مهم لأداء طويل الأمد. بالنسبة للشركات التي تسعى لتحقيق احتياجاتها الإنتاجية بكفاءة، فإن الاستثمار في معدات حقن القوالب عالية الجودة هو استثمار استراتيجي.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI