Divy strojů na vstřikovou formaci: Stroje na vstřikovou formaci, nebo IMMs jak se běžně říká v odvětví - zkratka pro stroje na vstřikovou formaci, jsou úžasnými artefakty výrobního sektoru. Tento typ stroje může vyrobit velké množství a širokou škálu produktů tak, že je téměř nemožné toto nepovažovat za nesmírně užitečné. Chcete-li pochopit, proč jsou IMMs důležité, zde je náhled do světa těchto artefaktů. Některé z klíčových výhod IMMs jsou: Schopnost převyšovat lidi v produkci v rozsahu, který je více než pouze ekvivalentní hled pointky výroby, ale také v rychlosti. Proces zahrnuje tavení polymerových granulátů, které jsou příměřeji stříleny do tvaru, kde se zhoustne a ztvrďuje plast do požadovaného tvaru. Hlavní důležitost spočívá v masové produkci, tj. vyrábění položek lot-to-lot identických současně v jednotlivých dávkových operacích. Energetická rovnost IMMs není cenná jen kvůli úsporám času a nákladů, ale i díky zajištění, že všechny vyrobené položky jsou konzistentní a přesně takové, jaké si osoba přeje, což je důvod, proč například výroba automobilů nemůže bez nich fungovat. Jak IMMs mohou zvyšovat produkční efektivitu. IMMs jsou nezbytné součásti používané k automatizaci výroby. Dříve byly většiny úkolů prováděny lidmi, což vedlo ke dlouhodobým plánům výroby a nadbytečné potřebě zdrojů. To dokazuje skutečnost, že stejná množství zboží by stála společnostem více času a zdrojů než dříve.

A dále, IMMs hrdě demonstруjí, jak se tvarují složité tvary na jednoduchých produkčních liniích. Uvažte o tvaru něčeho jako plastové láhve s vodou, která je těžká k manuálnímu výrobě. Umožňuje použití vlastních form a proto může být zařazena do masové výroby s využitím IMMs.

Pro ty, kteří se chtějí zabývat světem IMMs hlouběji, může být kompletní průvodce neocenitelnou zdrojovou informací. Takový průvodce se zabývá různými typy IMMs a jejich původem, až po detaily na úrovni aplikací. Poskytuje také faktory pro přijetí IMMs a uvádí jejich materiálové vlastnosti pro zpracování.

Tento průvodce obsahuje rozsáhlé vysvětlení procesu formování vstupkem, který je příliš komplikovaný pro čtenáře, aby ho porozuměl. Zahrnuje zkoumání procesu, ve kterém se plastové granuly stávají kapalnými, jsou vtlačeny do forem a pak ochlazovány, dokud se nezpevní. Bez této základní znalosti nemůže člověk pochopit, jak IMMs fungují.

IMMs revolucionalizují výrobu po celém světě! Co dělají?: Zlepšují efektivitu, zkracují časové hranice produkce a náklady! Výroba form prodloužených byla velmi drahá a trvala dlouho před příchodem IMMs. Stejným způsobem použitím IMMs mohou firmy zvýšit produktivitu bez marnivosti.

Navíc IMMs podporují inovační chování pomocí výroby přizpůsobených produktů. Stačí si jen pomyslet na pouzdra na telefony, s IMMs je možné tyto vyrábět ve mnoha různých tvaru/velikosti/barvy. Tento další stupeň přizpůsobení žádají spotřebitelé. -

SMBManufIMMndsMaking Manufacturing IMMs MatterBy SMBMANUFACTURING10/18/2015výroba malé a střední podniky immKolik z vás si škrábe hlavu, když mluvíme o Manažerském marketingu průmyslu (neboli IMM) ve výrobě?

Injekčně tvarované magnety mají mnoho společného s tím, jak se dnes provádí výroba, takže by bylo jen spravedlivé, aby člověk věděl, co to jsou a jak daleko jsou jejich aplikace důležité. Plní nejdůležitější funkci ve celém cyklu výroby; od tvorby formy po výrobu konečných produktů.

Fungují V PraxiBez tohoto by snadná složitá práce, která bez manuálních prostředků (bez jakéhokoli praktického přístupu), nepochybně nebyla schopna jiných úkolů. Jsou rychlé a vhodné pro vysoké objemy výroby, což snižuje náklady zatímco zvyšuje příjmy.

Na druhé straně jsou IMMs opravdu úžasné stroje, které naplnily výrobu revolucí. IMMs mění pravidla hry, urychlují čas výroby a spotřebitelé dostávají na míru vyrobený produkt. Tyto výhody jsou daleko od většiny dlouhodobě zavedených praktik, částečně protože provádějí tolik z vaší výroby jako každodenní nezávislý dodavatel skutečnosti.

IMM mají schopnost doslova vyrobit více než lidská práce na měřítku, které je ekvivalentní nejen v kvalitě, ale také ve rychlosti. Tento postup spočívá v tavení polymerových granulátů a střelení ho přímo do tvaru, který pak zhoustne a ztvrdne plast do požadovaného tvaru.

Významnou výhodou IMM je vždy možnost hromadné výroby, tj. produkce lot-to-lot identických položek současně v jednotlivých dávkových operacích. Celkově řečeno, jde o úsporu času, ale také o ekonomický přístup odstraněním manuálních prací. Vyrobené položky musí být také konzistentní a přesné, což je důvod, proč průmysl jako automobilová výroba nemůže bez nich fungovat.

IMMs jsou klíčové prvky používané k automatizaci výrobního procesu. Před automatizací byly většiny úkolů prováděny lidmi, kteří vedli výrobní projekty s rozsáhlými časovými plány a nadměrnou potřebou zdrojů. IMMs umožnily společnostem vyrobit obrovské množství položek v kratším čase než tradičními metodami.

Navíc zjednodušují složitý proces tvarování komplexních forem snadno na výrobních liniích. Pomyslete na reliéf přítomný například u plastové láhve na vodu, který by bylo obtížné vytvořit ručně. To umožňuje použití vlastních form pro tyto komplexní geometrie, čímž se stávají použitelné ve velkém měřítku výroby pomocí IMMs.

Úplný průvodce může být neuvěřitelnou investicí pro ty, kteří se chtějí ponořit hlouběji do světa IMMs. Takový průvodce vniká hluboko do toho, co jsou různé IMMs, jak fungují a jaké typy aplikací lze použít pro jejich nasazení. Dále uvádí výhody použití IMMs a vysvětluje termínologii materiálů, které lze zpracovávat.

Injekční formování obsahuje v tomto průvodci rozsáhlé vysvětlení pro čtenáře, aby porozuměli procesu. Zahrnuje přehled o tom, jak se plastové granuly proměňují na kapaliny, které jsou pak vtlačovány do forem a nechávají chladnout, dokud znovu neztvrdnou. Bez této základní znalosti nelze pochopit funkci IMMs.

IMMs mění herní pravidla výroby bezpo tak mnoha způsoby! Zvyšují účinnost, zkracují produkční časové linky a snižují náklady. Předtím, než byly IMMs zavedeny, byla výroba forem drahá a časově náročná. Použití IMMs umožňuje podnikům zvýšit produktivitu bez vytváření odpadu.

Navíc nám IMMs pomáhají přinést inovaci do provozu tím, že umožňují výrobu personalizovaných položek. Například pouzdra na telefon; s IMM můžete tyto vyrábět v mnoha designových možnostech - tvary, velikosti a barvy. Poskytuje to další stupeň personalizace a je proto atraktivnější pro spotřebitele.

SMBManufIMMndsMaking Manufacturing IMMs MatterBy SMBMANUFACTURING10/18/2015výroba smb imm_IMMSTěžíte si rozumět tomu, co myslíme pod pojmem Industry Marketing Management (nebo IMM) u výrobce?

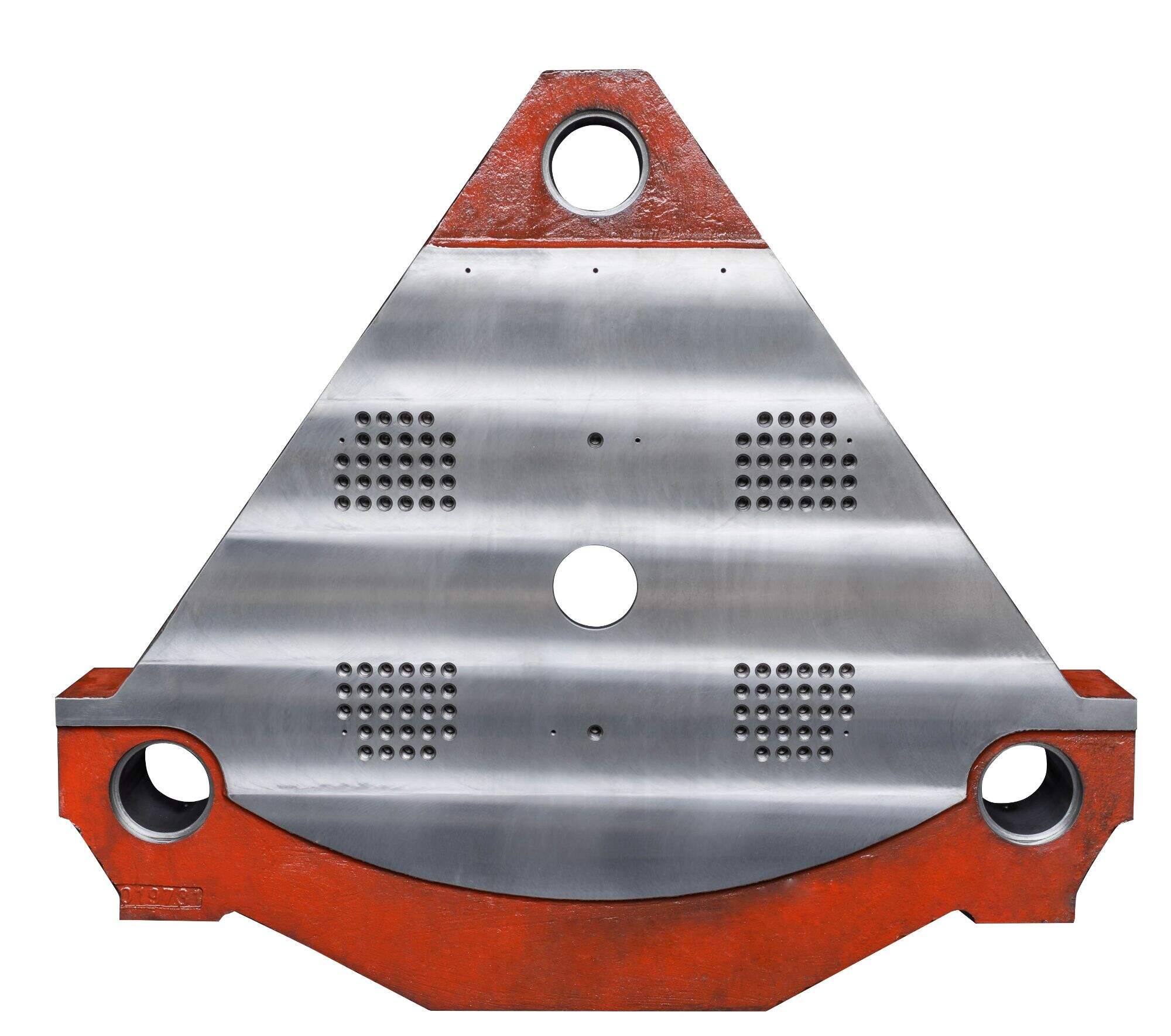

Injekčně tvarované magnety sehrávají klíčovou roli v dnešní výrobě, takže je důležité vědět, co jsou a jak relevantní mohou být jejich aplikace. Plní funkci hlavního prvkù pro celý cyklus výroby - od tvorby formy po výrobu konečných produktů.

Tento jednoduchý komplexní úkol lze dosáhnout bez praktičnosti, což by skutečně tak bylo, kdyby se vykonával ručně. Jsou rychlé a umožňují hromadnou výrobu, což véde ke snížení nákladů a nakonec zvyšuje zisky.

Naopak jsou IMMs opravdu úžasné stroje, které přinesly revoluci ve výrobě. IMMs revolučně změnily průmysl, zkrátily dobu výroby a poskytly spotřebitelům personalizovaný produkt. Vzhledem k jejich zapojení ve výrobě, které je tak integrováno do každodenního týmu s Aktuálností, uznání všech těchto výhod představuje vážný posun od konvenčních metod.

Pingcheng nyní domuje více než 20 výrobním strojům a více než 50 zkušeným technickým pracovníkům. Používají stroje pro vstřikování (IMM). Poté jsou výrobky kontrolovány měřicími přístroji společnosti Mitutoyo a souřadnicovými měřicími stroji (CMM), které jsou pravidelně kalibrovány. Dvojnásobná kontrola zajišťuje, že kvalita našich výrobků je přesná a stabilní. Každá jednotlivá součást může být během obrábění a montáže sledována a monitorována.

Dodavatelské řetězce a služby Pingchengu pomáhají strojům pro vstřikování (IMM) dosahovat obchodních cílů zákazníků. Zaměřujeme se na prodloužení a maximalizaci hodnoty a životnosti vaší výroby. PingCheng je spolehlivý výrobce, kterého hledáte. Jsme spolehlivým partnerem, který dokáže poskytnout příležitosti.

Pingcheng je plně integrovaný výrobce s vlastními injekčními stroji. Doprava našich výrobků je pouze začátkem našeho partnerství. Naše zákaznická podpora se zaměřuje na zajištění vaší spokojenosti. Více než 20 let poskytujeme výrobní služby a vybudovali jsme úzkou spolupráci s renomovanými japonskými společnostmi. Zásada upřímného cenového přístupu Pingcheng je založena na našich desetiletích zkušeností v odvětví a hlubokém pochopení tohoto segmentu. Po obdržení poptávky na cenovou nabídku analyzujeme technické výkresy ve specializovaném softwaru a předkládáme nejvhodnější řešení za přijatelné náklady.

Založeno na vlastních injekčních strojích a hlubokém porozumění podnikání se Pingcheng zavazuje poskytovat svým zákazníkům spravedlivé ceny. Po obdržení poptávky na cenovou nabídku okamžitě prozkoumáme technické výkresy a pomocí specializovaného softwaru provedeme simulaci, abychom mohli navrhnout nejúčinnější řešení za spravedlivé náklady.