Large buildings and machines are made stable with base flanges. Their main job is to make sure that pipes are kept connected, and by connecting these joints it should give strength and stability. Without them the pipes may lose their integrity causing hassles and preventing a lot of accidents.

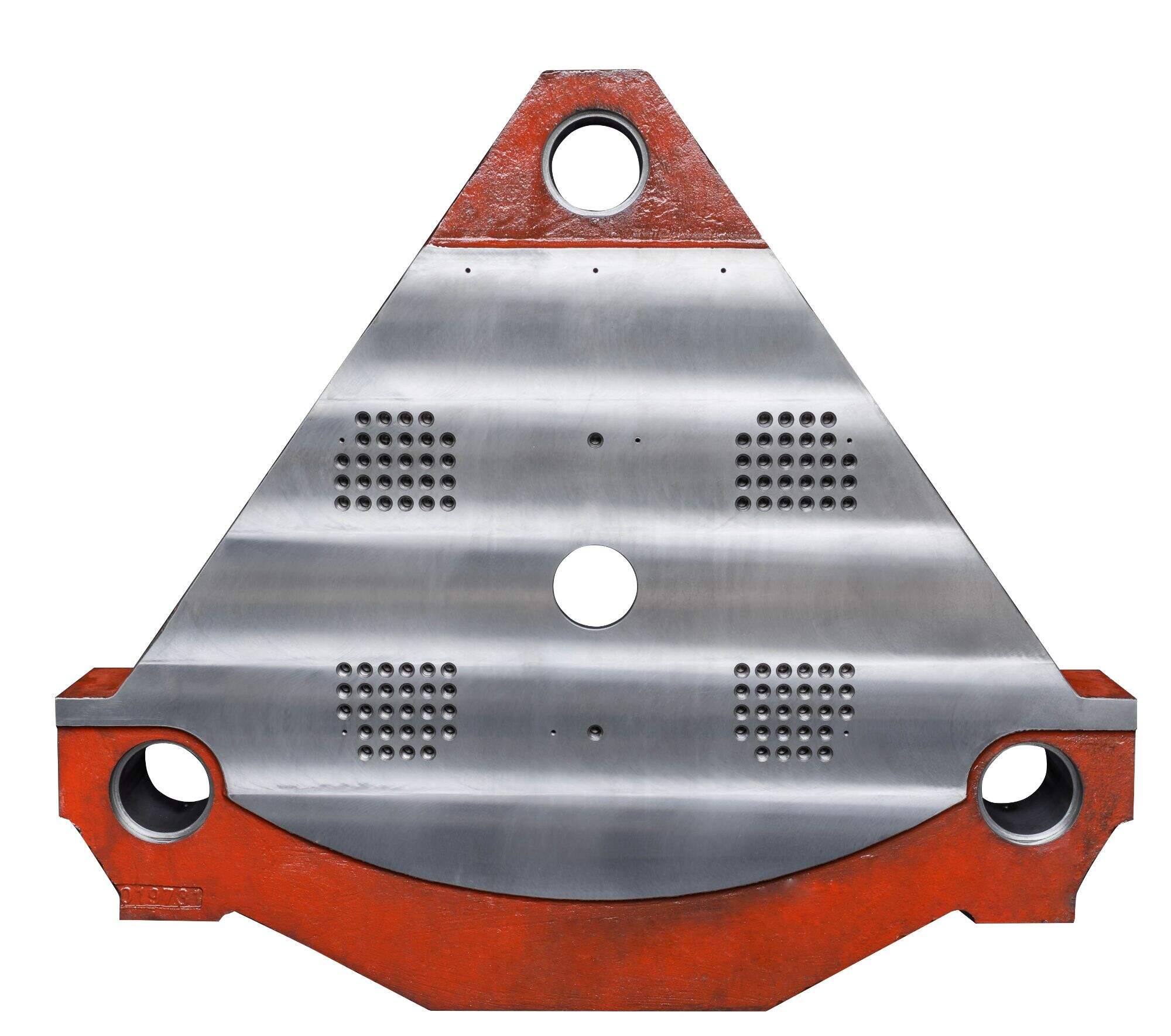

TYPES OF BASE FLANGEDAHLE base flanges serve multiple purposes Weld neck flanges are used, for example when the pipes must be welded whereas slip-on flanges can change to a pipe that requires a sliding connection. Blind flanges that are required to close the ends of pipes and ensure system integrity - Image by A&S Seals

Base flanges are an important aspect of the structural and civil engineering industry. The positioning of base flanges has to be done very carefully by the structural engineers as they bear identical loads imparted due to weight distributed over different pipes and also have its share load carried forward for other structure. Poorly selected base flanges could lead to the pipe falling off, so great care should be taken here.

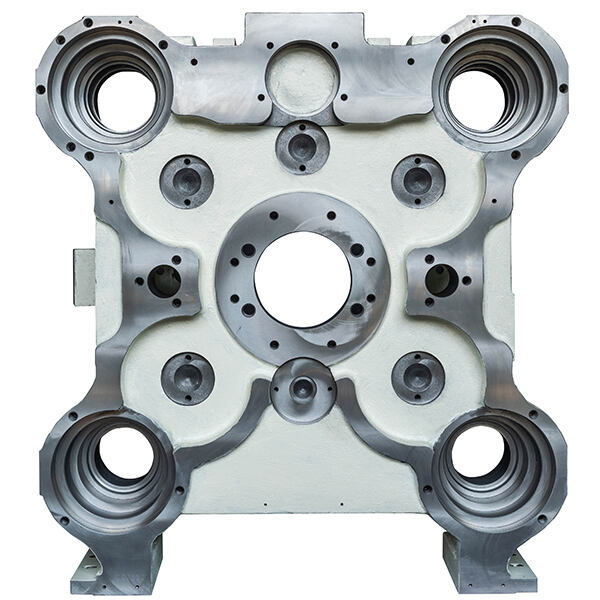

It is also used in equipment such as large air conditioners where base flanges come into play a major role. Base flanges are crucial when it comes to properly securing these connections, as each of the devices needs connected pipes in order to operate effectively. These flanges help to maintain the pipes and thus contribute towards extending the lifespan of machines, showing how base flange is indispensable in a wide range of mechanical systems.

Base Flanges need to be installed properly and maintenance has to become a part of regular practice in order Maintaining The Effectiveness conveyed above. Proper Centers should be tightened without over-stressing as to prevent the base plates from coming off or fatiguing the flanges Also, cleaning and maintaining the base flanges is important to prevent rusting and damage which will keep the shelf brackets functioning properly for a longer period of time.

Finally, the base flanges are important parts that support any structure or piece of machinery to make it stable and strong. Their wide array of uses span from connecting pipes in buildings to securing machinery work, which highlights their importance throughout the many industrial sectors. When we realize the sheer variety and utility of base flanges, people may learn to savour these humble anchoring agents that keep the world as one. The next time that you see a colossal structure or a mammoth machine, remember to greet Base Flange; silently applaud its pivotal contributions in maintaining the overall stability and performance level of these machines.

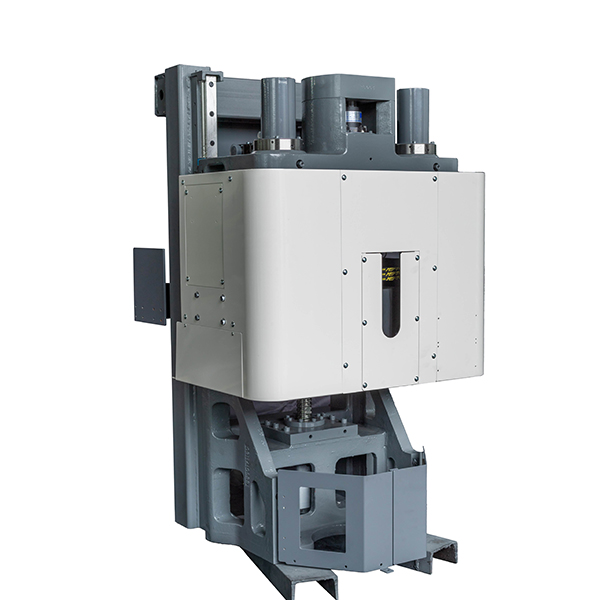

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a base flange you've been searching for. We are a partner which delivers opportunities.

Pingcheng today has more than 20 manufacturing facilities and more than base flange. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Our customers service focuses your satisfaction. We've been providing machining services and base flange with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng's base flange is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.