Have you ever wondered about how some of the toys your child loves, or cases that protect [so] many cell phones and even various pieces of plastic were made? Well, The key player in all of this is the injection molding machine. These machines are very important for molding the plastic into different every day used things and when its speed you need high-speed vertical injection moulding machine is known to be best!

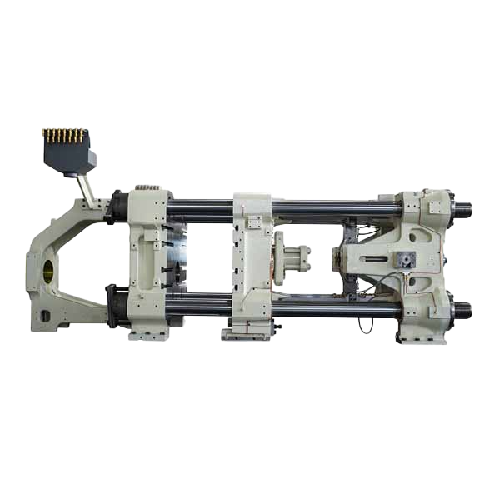

Horizontal-high-speed vertical injection molding machines are high performing and work effectively for making a considerable number of plastic parts within the short span. Their function consists of melting plastic pellets and passing the molten plastic into molds, subsequently obtaining forms similar to those we are accustomed to using in our day today. The whole manufacturing process has become faster and more efficient with the help of these high-speed machinery!

Biggest and most important of all are the engineers who being human design and built these machines. These are the masters of lightning-quick injection molding machines. To accomplish this, engineers must be extremely intelligent and creative. A high-speed vertical injection molding machine is nothing to toy with, and very serious engineers make sure they are both safe and efficient. This also involves using computer-aided design (CAD) software such as CAD and designing everything to perfection before the actual construction starts. CAD can also allow engineers to get perfect finish in their designs before going into manufacturing.

Production efficiency is the easiest thing to understand; it's the idea you produce things fast and easy. The vertical injection molding machinery at unbeatable speed of production efficiency They are products that allow to manufacture in a fast way many spans of plastic objects, which is interesting for companies looking to achieve great quantities. What is more, the high-speed machines are constructed to achieve a low energy footprint while maintaining an output quality which would make them green and feasible solutions.

The introduction of high speed vertical injection molding machines was nothing short than a revolution to the Injection Molding industry. The old manufacturing process was much slower, with factories only able to produce a small quantity daily before these more sophisticated machines were introduced. But modern production line factory is machine operated, which rapidity the process. Factories that are able to produce goods more quickly and in bigger quantities can churn out more products, make higher profits, and help protect the environment.

High-speed vertical injection molding machine engineers are always working to improve the work. Their aim is to create more efficient, user-friendly and ecologically sustainable machines. The industry may also see a rise in the number of fast-speed injection molding machines that will be located in factories across the globe. The expansion could generate the development of a greater variety of mainstream plastic products, such as toys or phone cases and automotive components. These devices are actually must-have tools for improving the production process and also participating in conservation, particularly high-speed vertical injection molding machines. These exceptional machines are indeed the future of more efficient and environmentally-friendly manufacturing.

Pingcheng is committed to helping customers realize their business goals through our supply chain and high speed vertical injection molding machine. We concentrate on helping you increase the lifespan and potential value of your products. PingCheng can be the reliable manufacturer that you need. We are a trustworthy partner that can provide opportunities.

Our customer services focuses your satisfaction. We've been providing the machining services and high speed vertical injection molding machine with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.

Based on decades of experience and high speed vertical injection molding machine, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

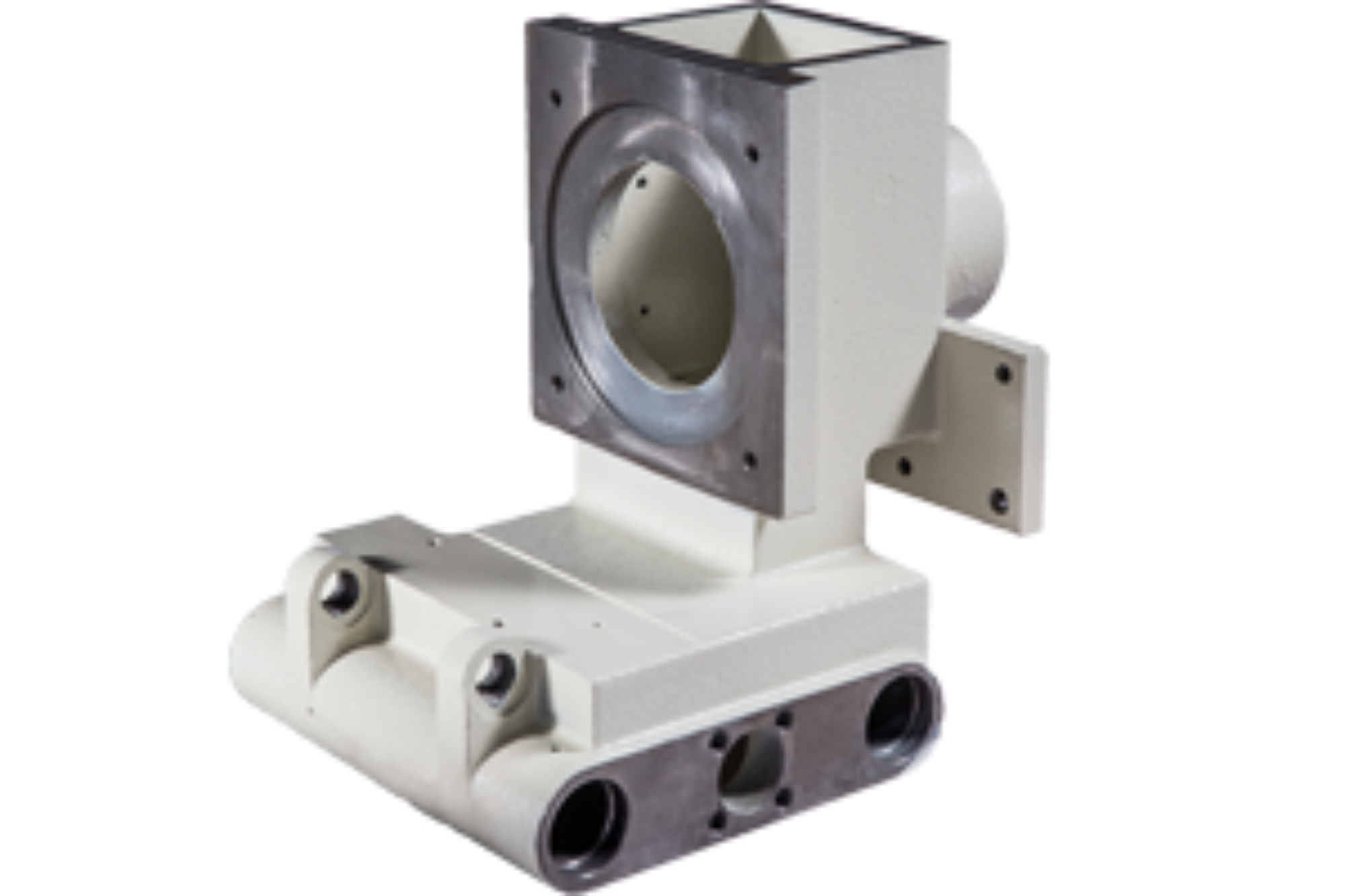

Pingcheng today has more than 20 manufacturing facilities and more than high speed vertical injection molding machine. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.