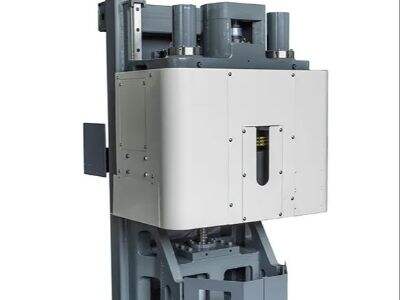

It’s VERY important to use vertical injection machines for making complex mold. Molds are forms that you use to make things out of plastic and other stuff. They do this by spraying material into a mold from the bottom up, unlike other machines that inject it into the mold from the side. This technique can help ensure that the material thoroughly fills the mold in a uniform way, which can be crucial if the mold is a complex shape. Pingcheng, as a leader, to apply this technology to produce high quality molds.

Increased accuracy and precision in the production of geometrically complex rotor molds

Vertical injection machines are really good in making molds that have product with a lot of detail and that are a weird shape. Since they push material in from the bottom, material is more easily distributed to all the nooks and crannies in a mold without leaving a mess. This means that the end result is a cover that looks exactly as it was supposed to, with all the little things in just the right place. Without a vertical injection machine like this, it would be very difficult to accurately render complex shapes.

Pro In Production of precision molds with vertical injection technique.

Vertical injection machines help make the molding process faster and simpler. Because the material is injected from the bottom into the mold, the mold can be filled rapidly and uniformly. And it’s also less risky, too, because there’s less of a chance we’ll have to shoot parts, which can slow down production. This vertical injection molding machine is good for business because companies can make more molds in less time.

High Efficiency and Quality Problem of mould making complex moulds.

Efficiency means doing things quickly without wasting time and materials, and quality means producing things really well. Both are accomplished using vertical injection machines when making complex molds. They operate more rapidly and make fewer errors, meaning less material goes to waste. Added bonus, their molds are super quality and look just like they should so nothing but happy customers.

The advantage of vertical injection molding machines in mold consistency and accuracy.

With vertical injection machines, companies can create molds that they could not before because the machines can handle very complex designs. Designers can be less concerned about whether their designs are too complex to be molded. That can free them to be more creative and innovative and, ultimately, to produce better products.

Tackling the complexities of complex mold production with vertical injection technology

The production of complex molds can be very difficult. Shapes can be complex, and the substances used can be difficult to manipulate. But vertical injection machines, such as those from Pingcheng, are designed specifically to meet these challenges. They offer the accuracy, speed and flexibility to produce even the most complex moulds and allow companies to remain competitive in their marketplace.

Table of Contents

- Increased accuracy and precision in the production of geometrically complex rotor molds

- Pro In Production of precision molds with vertical injection technique.

- High Efficiency and Quality Problem of mould making complex moulds.

- The advantage of vertical injection molding machines in mold consistency and accuracy.

- Tackling the complexities of complex mold production with vertical injection technology

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI