The Hydraulic Cylinder Stroke is the distance (in mm or inches) that one piston within a cylinder travels from end to other. Think of it as a drawer that opens and closes, like this It is the motion behind a great many working methods of shoveling, or sweeping objects along by scooping them. The force in hydraulic cylinders is created with oil. An oil pushed the thing and it pushes a piston. The only thing it does is change the direction of what ever you are trying to move ie lift or push.

The most critical factor regarding the hydraulic cylinder of your machine is surely the stroke length of piston move. This is the travel distance of a piston from one extreme to another and it needs also to match more closely with your intended use. For you, this would mean that a longer stroke length will allow the piston to move it even further if are trying to lift something heavy. The exact stroke length can make your machine more effective, if it allows the equipment to do what you need but is not so lengthy as frictional resistance causes excess rubbing time while far too much of a body section gets into certain areas with cutting potential.

To Improve the performance of a machine, one among best ways is to stroke an Hydraulic Cylinder effectively. Stroke - With stroke, you can change the speed and power of piston. It's like saying you don't have a bike speed. More you pedal faster, more it goes. It also helps with fuel economy meaning it uses less energy and your machine does not wear so fast (also reduces the need to purchase a new one every few years). While, the machine consumes less power and carry out its work faster by optimizing stroke.

There are devices that employs hydraulic cylinders and sometimes, they can fail. What are the Problems - Some of issues that occur in these parts here include- an oil leaks when it comes out from there and piston does not move freely or weird noise come out of cylinder. It might as well be the warning signs If you attend to these fixes, it can prevent sewing machine issues and ensure smooth functioning of your sewing device. Frequently scheduled maintenance can help prevent problems from growing into large ones. It is in the way you would take your sick pet to see a vet, if they looked out of sorts.

This is one more of the things, that will help your machine to work as per how well or not too good it is available in contact with high carbons. Picking an apt stroke length and how fast the piston gets moving are in here, but for most of it it really also amounts to making a faster machine better is made so that its job does not takes much longer. This saves time and money. If a machine is faster than another one, that means it completes tasks sooner and you can do more in less time. Learning such designs of hydraulic cylinder, eases your work process and makes it more efficient.

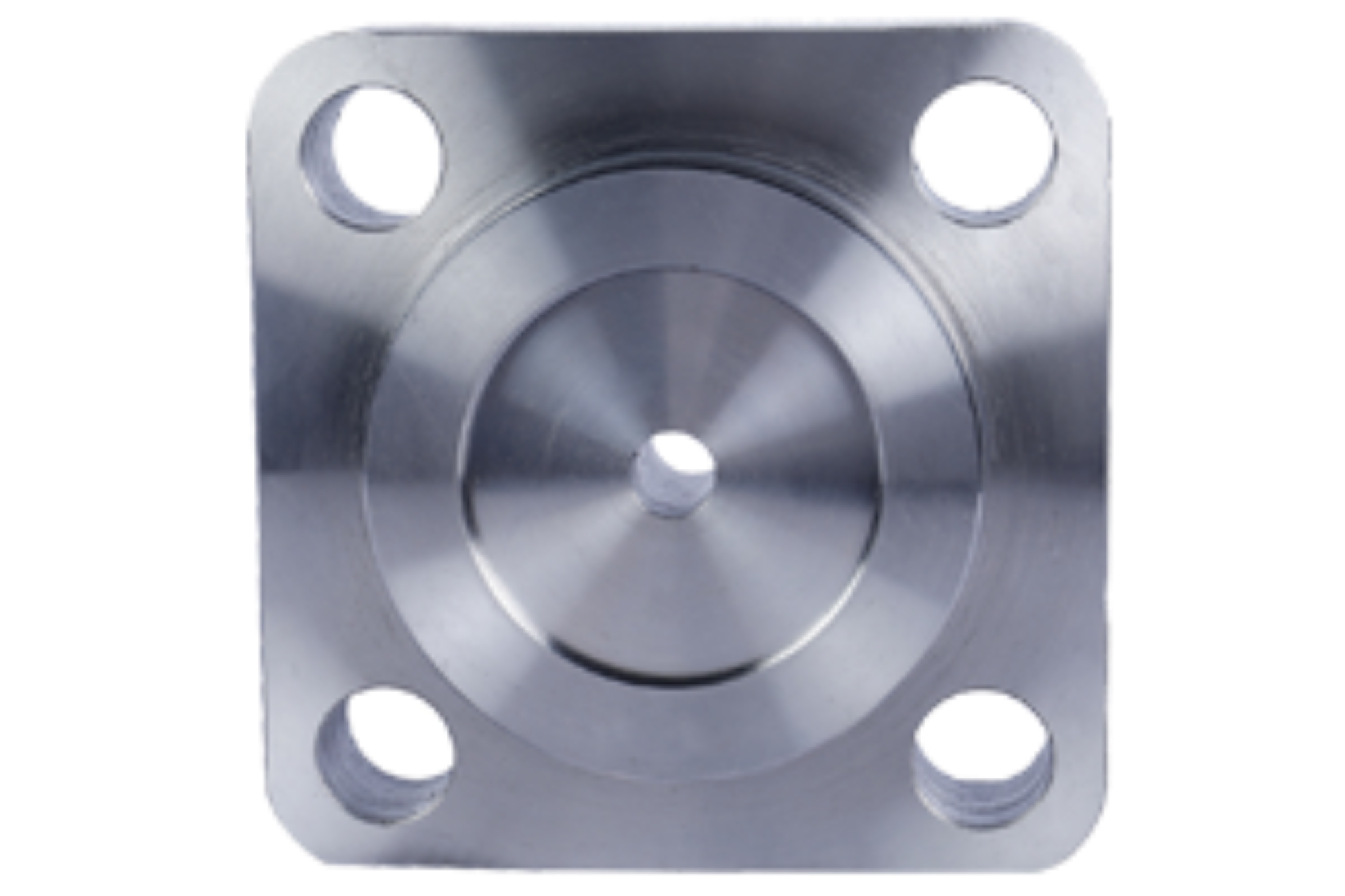

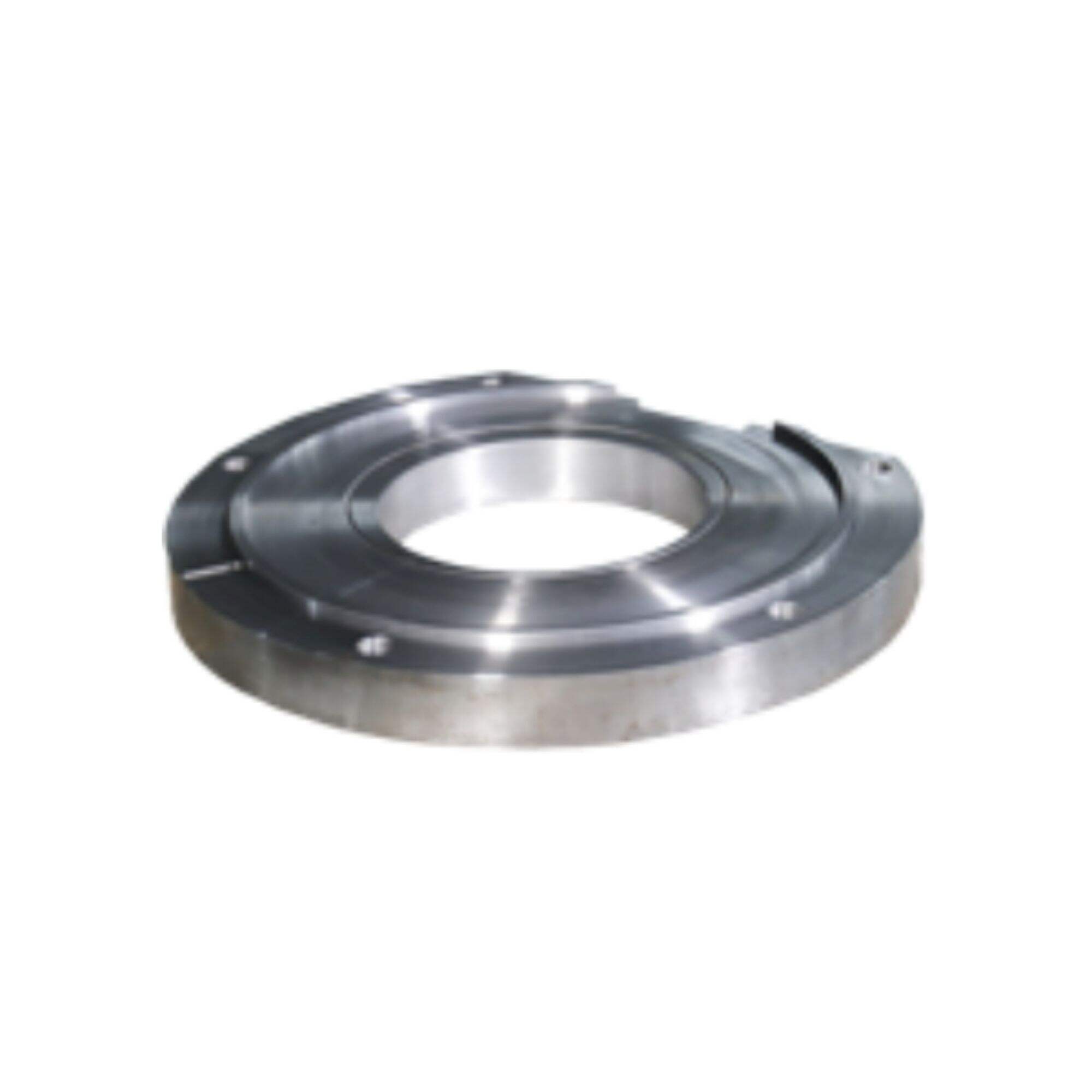

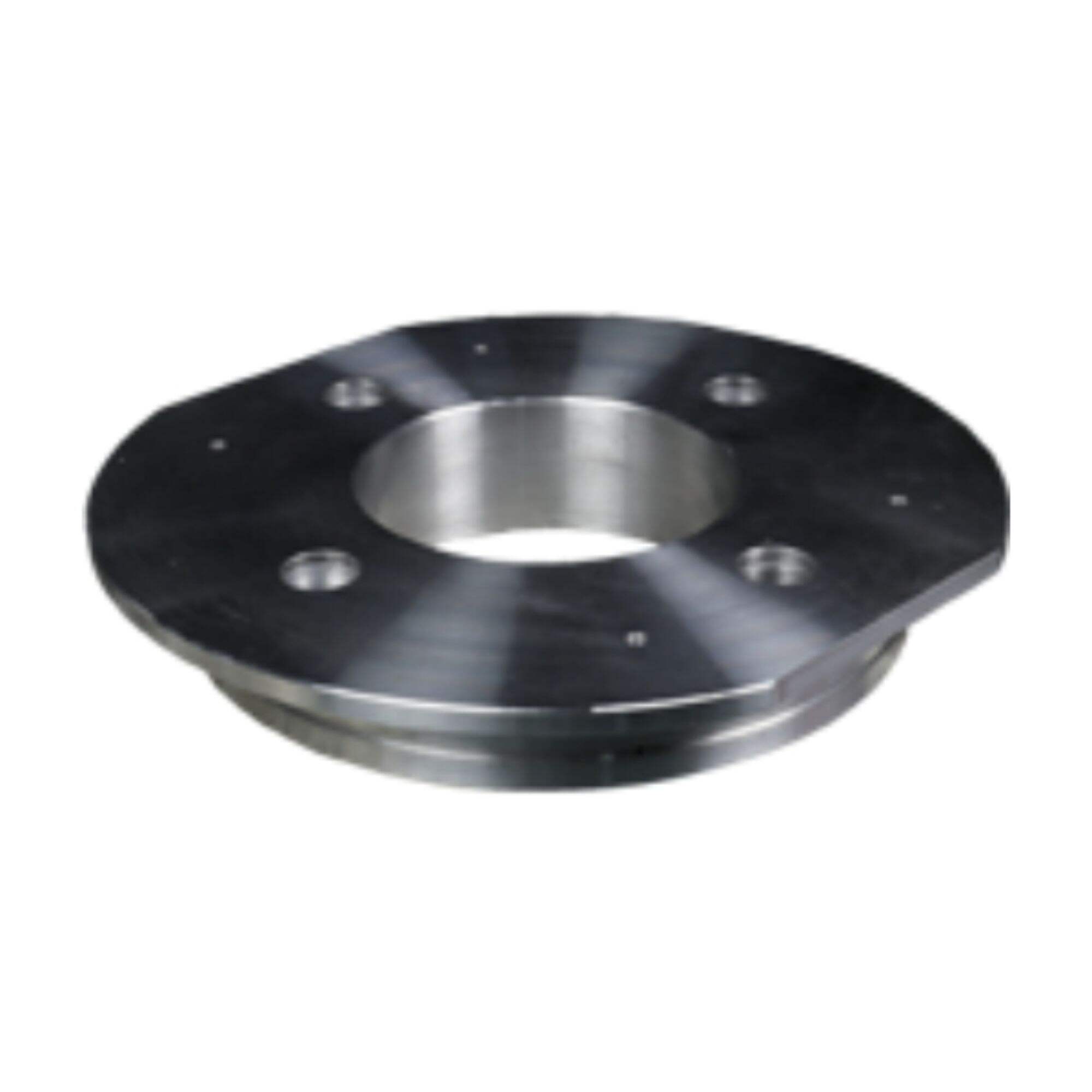

Our customer services focuses your satisfaction. We've been providing the machining services and hydraulic cylinder stroke with industry-renowned Japanese businesses for more than 20 years. Based on decades experience and knowledge of this industry, Pingcheng is dedicated to giving customers honest prices. Once we get a quotation requests, we look at the drawings and simulates using specialized software immediately, and offer the best solution with proper prices.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We hydraulic cylinder stroke, recreate it in specialized software, and then provide the most competitive price.

Pingcheng is committed to helping customers achieves their business goals through our hydraulic cylinder stroke and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng has now more than 20 manufacturing machines and hydraulic cylinder stroke with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.