Pingcheng specializes in CNC machine controllers. But what, you ask, is a motor controller? Motor controller act as the brain of CNC machine. It advises the motors of their speed and direction in which they must turn. A CNC machine cannot do its job properly without a motor controller.

So using a motor controller actually starts with instructions from a computer. Similar is the case with CNC machines as they too need instructions on what to do. Next, the electric motor slide base controller converts these instructions into commands for the motors that they can recognize and execute. The computer then communicates these signals to the motor controller through the wire (or wirelessly). These signals are then amplified by the motor controller so that the motors can operate properly and perform the tasks that you would like them to complete.

You might want to improve the efficiency and performance of your Pingcheng CNC machine if you own one. A good way to solve that is to get a better motor bearing housing controller. The right motor controller can make your CNC machine run smoother and faster than ever. This means that you can achieve your projects faster and with fewer headaches. A better motor controller can also allow you to fine-tune how the machine moves. It is very useful while working on details and having precision.

Lets quickly touch on some important considerations when selecting a motor controller for your CNC machine. 1- Ensure motor controller compatibility with your particular CNC machine Not all controllers are compatible with all machines, making this a crucial step. Second, ensure that the motor controller can accept the power required by your machine. Larger CNC machines or those that need more power will require a more powerful motor controller to run effectively. Finally, consider motor controller features. Advanced and unique features are provided by some controllers that help you use your CNC machine to the fullest potential, so you can make more complex and creative works.

Just like any other machine, once in while a CNC machine might face issues with its motor controller. Some known issues are for example when the motors do not move the right way or when the machine does not respond to the computers commands. These problems may arise for various reasons, be it issues before the motor controller, in the motor controller or in the wiring that connects the computer to the motor bearing cover controller.

Check Wires If you happen to have an issue with your motor controller, the first thing you want you to do is check the wires. Ensure that all cables are tightly connected, and there are no breaks or damaged wires. If the wiring checks out and looks good, you may need to buy a new motor controller altogether. In addition, Pingcheng offers top-quality motor cover controllers that harmonize with types of CNC machines, so you're able to get the right fit for your needs.

Motor controllers are becoming increasingly sophisticated hand in hand with technology advancements. In recent developments, some motor controllers can control multiple motors with a single controller. It will help to make your CNC machine more efficient and simple-to-use. The use of wireless communication between the computer (normally a PC) and the motor controller also means you are not tethered to the equipment by cables and can arrange the workspace as is simplest for you.

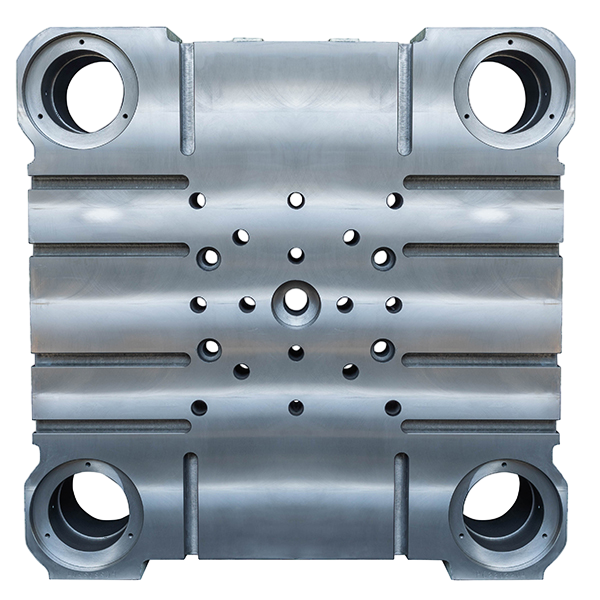

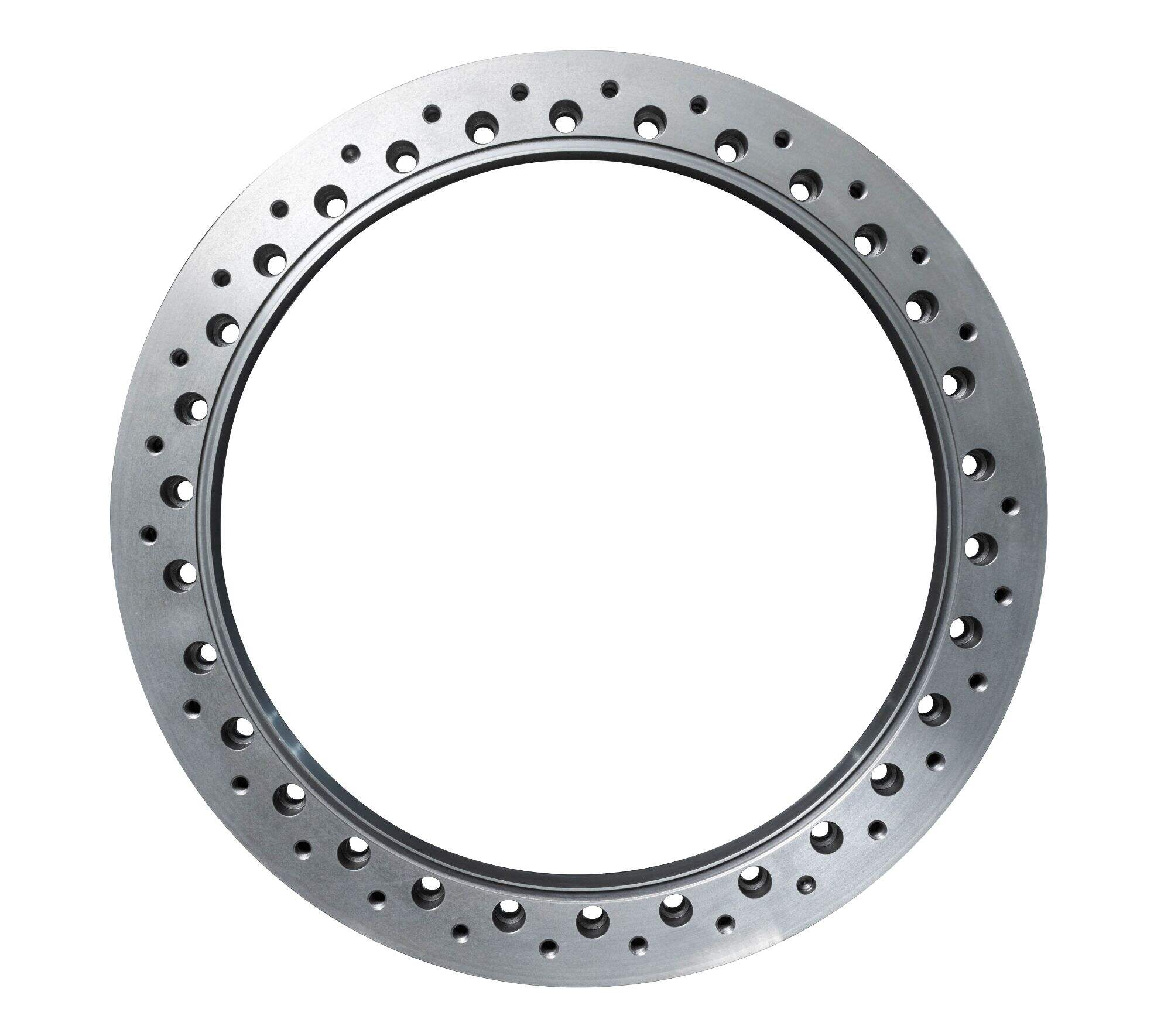

Pingcheng now Cnc motor controller and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

Pingcheng is Cnc motor controller achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Based on Cnc motor controller and knowledge of the business, Pingcheng is dedicated to giving customers honest prices. We analyze the drawing, recreate the drawing using software that is specialized, and then offer the best price.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our Cnc motor controller. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.