They are used in machines to allow the smooth motion along a straight line ranging from electronic equipment and machinery. These bearings keep everything in line and are needed to make sure things pivot back and forth smoothly. In this post, we will discuss the mechanics of linear slide bearings and reinforce their importance in machinery.

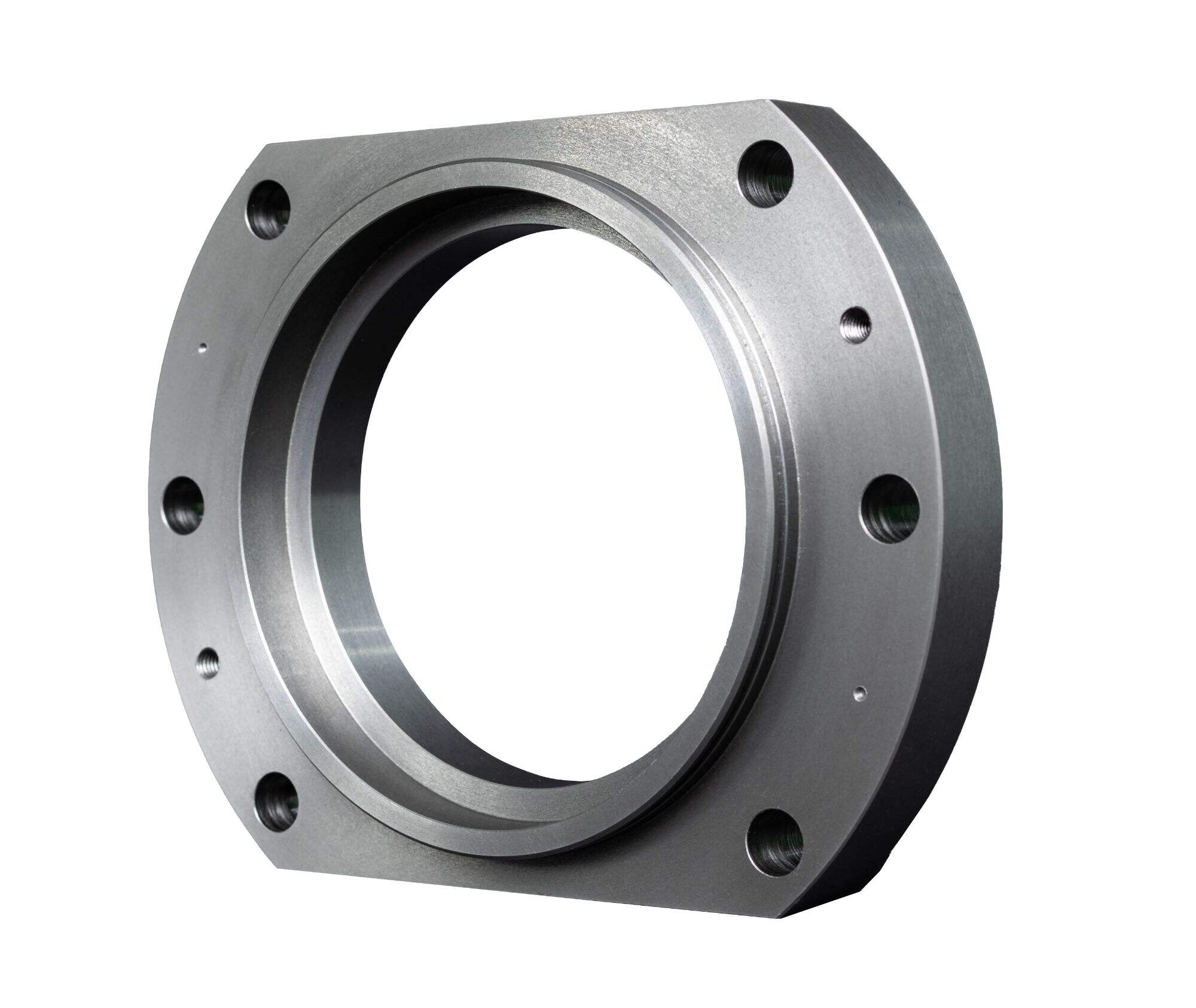

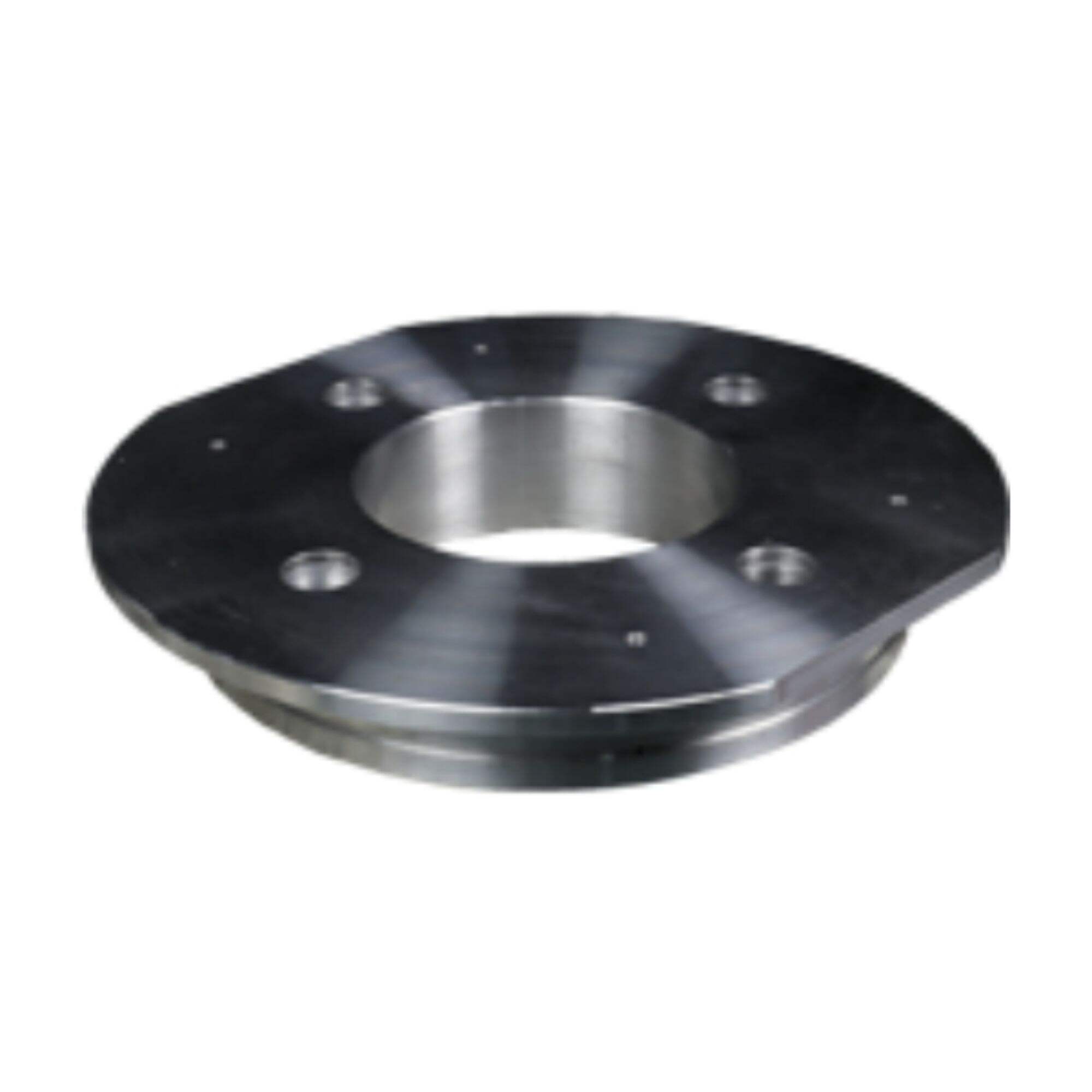

Partial mechanism of operationLinear slide bearings provide two metal components to move against each other, which forms a low-friction surface that allows free movement. And, much of the time these metal parts are coated with special coatings to reduce friction even further for that added fluid and unrestrictive movement.

Linear slide bearings are an important part of the machines, which require accurate vertical or horizontal movement and need smooth low-friction slides for good motion control. Our slide bearings of highest quality are made from robust materials and thus convinced they will give a lot more years of constant frictionless work.

How to maintain the original accuracy and prolong lifespan of linear slide bearing

Linear slide bearings help in the accuracy and durability of machines as they provide with level surface that does not wear out easily even when being used by a longer time. To get the best out of your machine and to ensure that it lasts for a long time, going with high-quality slide bearings is absolutely essential.

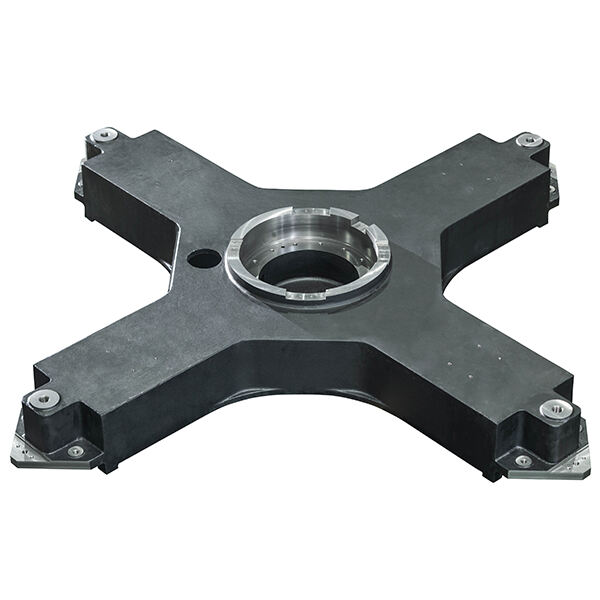

One area of challenge is selecting the correct linear slide bearings given how many types there are to choose from, including different design strengths and weaknesses. It is essential to verify exactly what your machine demands prior choosing appropriate bearing whether bearings are being needed for high-speed operations or heavy load applications.

Advanced linear slide bearings technology can greatly diminish friction and wear within your machine. This is a state-of-the-art technology implementation that includes unique lubricants and materials to reduce the friction, along with ultra precision manufacturing for a super slick low friction surface. Taking on these advancements now could ensure that you get the most out of your machine(...or at least give her a chance to live longer), in turn increasing its duties, moving forward.

Essentially, a linear slide bearing is that component of the machine which dictates how it moves without friction and glides through reducing wear on moving parts. Choosing better slide bearings and adopting advanced technologies will give your machine higher accuracy, reliability. Hopefully this in-depth conversation has brought to light the importance of linear slide bearings and how they work.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our linear slide bearings. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Based on decades of experience and linear slide bearings, Pingcheng is dedicated to providing its customers with a fair price. We examine the drawing, model it with specialized software and then give you the most affordable price.

Pingcheng today has more than 20 manufacturing facilities and more than linear slide bearings. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Pingcheng is committed to helping our customers reach their goals in business through our own supply chain and services solutions. We are focused on helping to extend and linear slide bearings of your products. PingCheng is a dependable manufacturer that you're searching for. We are a trustworthy supplier of opportunities.