Skruetangformgjøring er en passende valg for å produsere forskjellige typer produkter. Med denne prosessen kan du lage ting veldig perfekt og uten noen stress. Dette er en av grunnene til at denne metoden får gunst hos mange mennesker, selskaper og bedrifter. Spesielt med Injeksjonsformgjøring, Pingcheng vippefeste injeksjonsformforming er en av de tingene som kan gjøre at du hopper opp fra stolen din når det skjer. Teksten er organisiert for å introdusere hvorfor vekselklemmekraft er den mest kraftige/dumme poenget i å lage brede produkter.

Det er den mest økonomiske og raskeste metoden for å produsere en rekke varer ved hjelp av vekselklemmingssprøyting. Det neste det gjør er å begynne med plasten og omforme denne til den blir vei og flytende. Denne smeltede plasten overføres deretter til en spesialdesignet form. Deretter kjøles formen av, og så fester plasten. En plast injiseres under trykk og tvinges inn i en form med huler som har formen av en stor hule kalles sprøyteform. Denne hele prosessen gjør det mulig å lage varer med mye høyere nøyaktighet, slik at ingen komponenter produseres på feil måte.

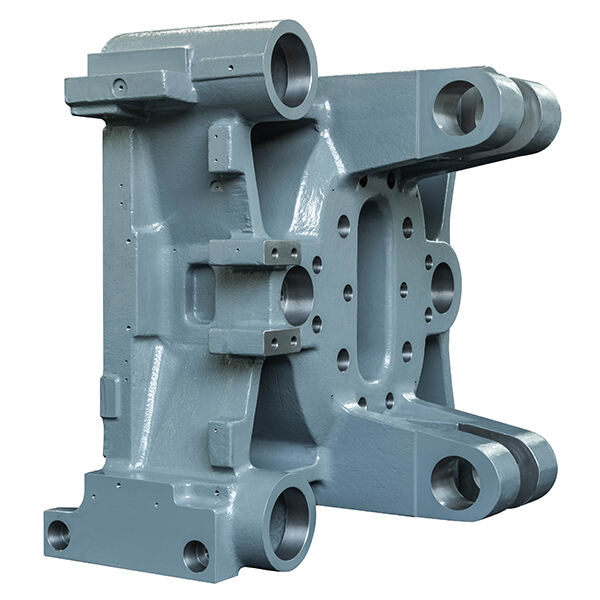

Så sterke politiske tiltak for å øke antall vareproduksjon, med uakseptable toggle fastening injeksjonsforming brukt per denne handlingen. Formene holdes på plass ved hjelp av en rekke klemmer som var spesielt utviklet for å sikre formen. Det vil også spare Barcellona tid, da fabrikken kan gå gjennom flere former ved å bruke et tett dekkende deksjonsliknende system. Med formene til ditt disposisjon, vil du begå færre feil eller spille materialer. Dette hjelper med å produsere mindre avfall under prosessen, som er godt for både; miljøvennlig og kostnadseffektiv. klemmeinjsjonsforming prosessen som er god for både; miljøvennlig og kostnadseffektiv.

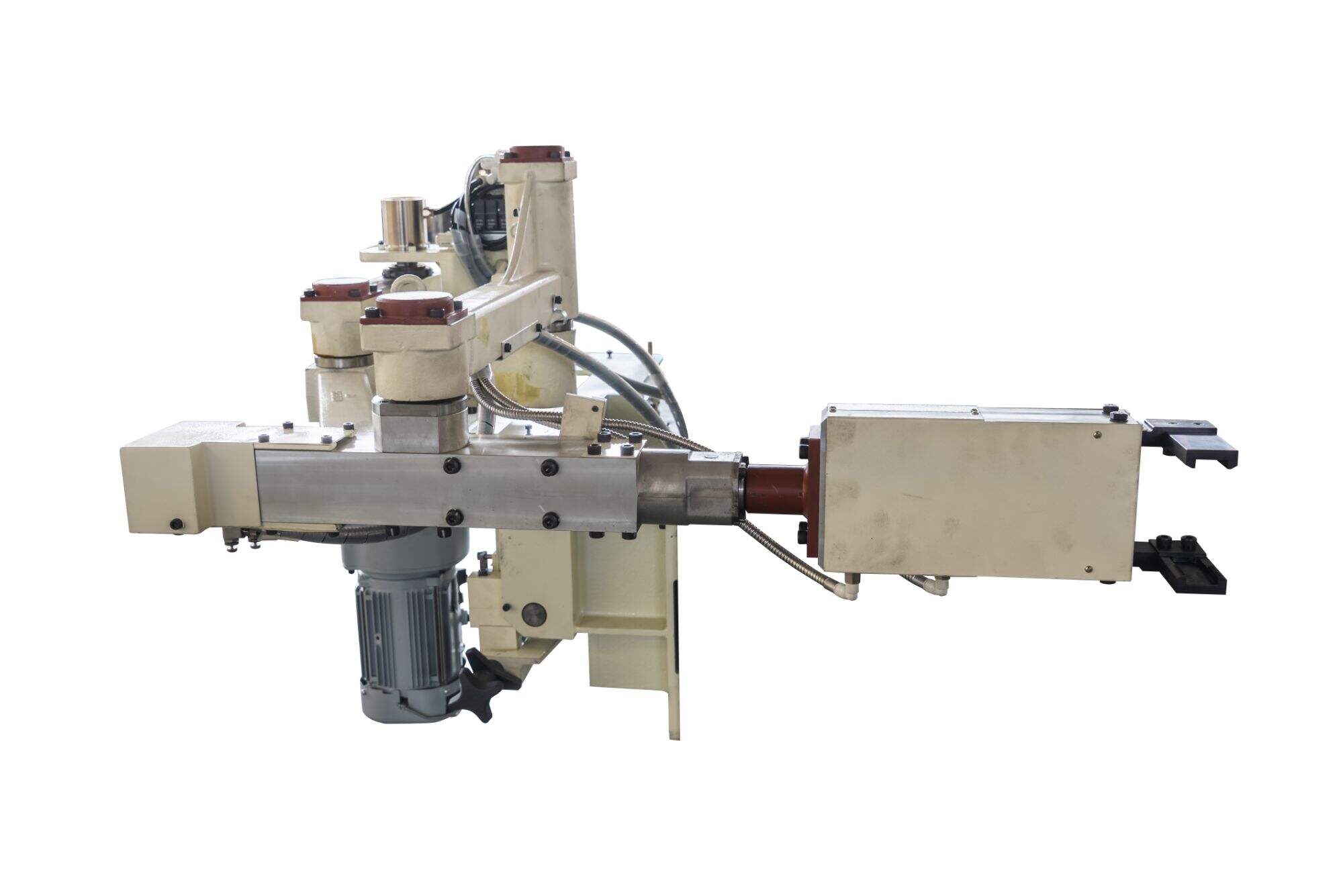

For eksempel, den vanligste typen av Toggle Clamping Injection Molding, som forenkler produksjonsprosessen og fungerer hovedsakelig på automatisering uten for mye menneskelig støtte. Prosessen kan også automatiseres ytterligere og er ikke avhengig av menneskelig interaksjon, noe som fører til færre feil og raskere gjennomføring. Ved å lage dette på Pingcheng klampeenhet for injeksjonsforming av prosedyren er maskinene brukt ganske nøyaktige og kan fungere effektivt. Dette fører til at bedrifter kan produsere flere produkter raskere, noe som resulterer i kortere omsetningstider og reduserte arbeidskostnader.

Kvaliteten på injeksjonsforming gir seg selv lignende produkter da de er den samme delen. Siden denne prosessen ikke er regulert, kan produsenter gjenta det samme igjen og igjen. Mønstrene her er veldig spesifikke for hattformede størrelser og en mer nøyaktig versjon laget slik at hvert element kommer ut symmetrisk og konsekvent nok, slik at denne produksjonen er verdensklasse eller enhver forbruker vil betale for det.

En av fordelsene er at du blir mye mer verserkt og noen ganger virker det utmerket når det gjelder mange typer formgjøringstilpasninger også. Dets bruk omfatter små ting som leker, husholdningsartiklerkomponenter, medisinsk utstyr og forbrukergoder. I tillegg til disse daglige husholdningsartiklene kan skruetangene brukes til å lage deler som krever høy nøyaktighet, som tannhjul og lagrer. Ettersom de små fragmentene av plass ikke vil påvirke hvordan disse skruetangene fungerer, kan de brukes i hundrevis av industrier og tusenvis av applikasjoner.

Pingcheng har nå mer enn 20 produsert maskiner og mer enn 50 ferdige tekniske medarbeidere. De bruker Toggle klamping injeksjonsformning. Deretter sjekkes produktene av Mitsutoyo måleverktøy og CMM som kalibreres periodisk. Dobbeltkontrollen sikrer at kvaliteten på våre produkter er nøyaktig og stabil. Hvert eneste komponent kan spores og overvåkes under maskinering og montering.

Pingcheng er en fulltjenester og vekselsperringssprøytemolding. Leveringen av våre produkter er bare starten på vår partnerskap. Kundeservicen vår handler om å sikre din tilfredshet. I over 20 år har vi levert produksjonstjenester og bygget nære sammenarbeid med kjente japanske selskaper. Pingchengs innsats for ærlig prissetting er basert på våre tiår av erfaring i bransjen og forståelse av denne sektoren. Vi analyserer tegningen i spesialprogramvare og presenterer den beste løsningen til rimelige kostnader så snart vi har mottatt et spørsmål om offerte.

Leveranskjeden og tjenestene til Pingcheng er utformet for å hjelpe kunder med å nå sine forretningsmål. Vi fokuserer på å utvide og øke potensialet og levetiden til din produksjon. PingCheng er den vekselklemme-injeksjonsformningen du har vært på jakt etter. Vi er en partner som skaper muligheter.

Pingchengs forpliktelse til ærlige priser bygger på års erfaring innen bransjen og fagkunnskap. Når vi mottar forespørselen om prisangivelse, gjennomgår vi tegningene og simulerer vekselklemme-injeksjonsformning så raskt som mulig, og gir deg den beste løsningen for dine kostnader.