Turbinele eoliene sunt mașini foarte mari care produc energie electrică bazată pe forța suprafeței. Ca parte a energiei regenerabile, acestea sunt utilizate pentru a genera energie fără a folosi resurse naturale. Mânde adânc în interiorul unei turbine eoliene se află ceea ce numim cutia de viteze. O parte deosebit de specială este cutia de viteze care transformă energia eoliană în putere mecanică. Această energie mecanică, la rândul ei, generează electricitate care poate fi folosită pentru a alimenta casele și afacerile noastre.

O cutie de viteze este o mașină de genul său, poate varia viteza cu care ceva se mișcă. O turbină eolică este un dispozitiv care reduce rotirea rapidă a pârghiilor (când există vânt puternic) prin intermediul de viteze. Acestă reducere are loc pentru că echilibrează turbină eolică astfel încât, când se rotește corespunzător de repede și nu este supradusă de vânturi violente sau rafale de aer, să funcționeze în siguranță. În același timp, aceasta face și ca generatorul să se rotească rapid și să producă electricitate. Este foarte similar cu pedala mai repede pe un bicicletă pentru a merge mai repede, unde cutia de viteze ajută generatorul să performe mai bine.

Există mai multe componente principale care funcționează împreună în cadrul funcționării cutiei de viteze a turbinelor eoliene. Roțile, șarpele și uleiul sunt părți ale acesteia. Roțile se află în interiorul cutiei de viteze, ca dinți pe un spate, și se rotesc între ele pentru a schimba viteza de deplasare și direcția mișcării. Șarpele sunt prevăzute pentru funcții delicate; similare cu articulațiile umane care ne ajută să ne încovoiem și să ne întoarcem. Și în sfârșit, avem nevoie de ulei pentru a menține totul rece și pentru a ajuta componentele obișnuite să nu se supraîncălzească când sunt sub o sarcină grea.

Este esențial să monitorizați și să mențineți cutia de viteze a turbinelor dvs. eoliene dacă doriți ca aceasta să funcționeze perfect și eficient. Corpul nostru are nevoie de întreținere și, la fel, mașinile au nevoie de serviciu. Verificarea nivelului de ulei din cutia de viteze este una dintre aceste sarcini. Dacă nivelul este scăzut, pur și simplu adăugați mai mult ulei până la nivelul corect. Acest lucru menține toate piesele reci și se asigură că acestea funcționează împreună perfect.

Este la fel de important să examiniți roțile și antrenamentele. Dacă roțile sau antrenamentele încep să se use, ceea ce poate să se întâmple după 10+ ani de utilizare într-un deschidător de porțișoare de gară (în funcție de cât de des este folosit), întreaga sistem va fi afectată. Înlăturați-l atunci când observați semne de avarie imediat. Acest lucru poate să ajute să evitați probleme mai mari curând.

Supraîncălzire: Când temperatura în jurul cutiei de viteze devine ridicată, în acest caz aceasta nu va funcționa corect și poate provoca avaria componentelor, ceea ce le duce să se use mai repede. Această cantitate excessivă de căldură poate apărea când nu există o lubrificare potrivită sau când antrenamentele în sine sunt use. Dacă este cazul, trebuie doar să adăugați ulei sau să înlocuiți ceea ce determină funcționarea incorectă.

Există câteva considerente cheie atunci când alegeți următoarea cutie de viteze a turbinii eoliene. Lucruri precum dimensiunea și greutatea turbinii tale eoliene, felul de vânt pe care îl ai în regiunea unde locuiești, și câtă putere este necesară sunt unele dintre caracteristicile principale care vor influența această configurație. Toate cele de mai sus devin importante pentru ca acest lucru să funcționeze drept o cutie de viteze a turbinei eoliene.

Pingcheng este dedicată ajutării clienților noștri să-și atingă obiectivele în afaceri prin propriile soluții de lanț de aprovizionare și servicii. Ne concentrăm pe extinderea duratei de viață și pe întreținerea reductoarelor pentru parcele eoliene ale produselor dumneavoastră. PingCheng este un producător de încredere pe care îl căutați. Suntem un furnizor de încredere al oportunităților.

Angajamentul Pingcheng privind prețurile corecte se bazează pe ani de experiență în domeniu și pe cunoștințele acumulate. După ce primim cererea de ofertă, analizăm desenele și simulăm reductorul pentru parcele eoliene cât mai repede posibil, oferindu-vă cea mai bună soluție din punct de vedere al costurilor.

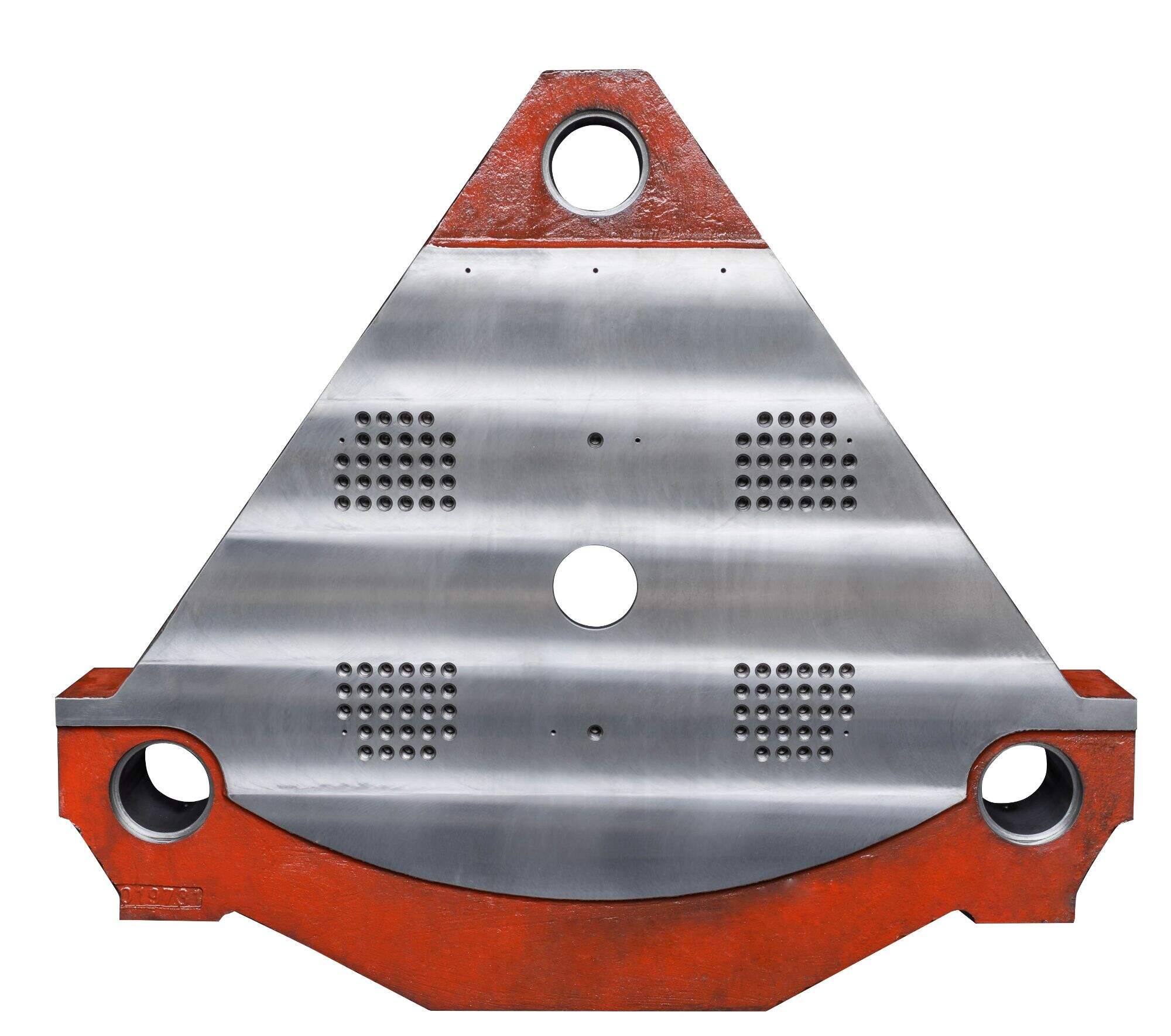

Pingcheng găzduiește în prezent peste 20 de mașini de fabricație și peste 50 de specialiști tehnici calificați. Aceștia asamblează reductoarele pentru turbine eoliene. Apoi, produsele sunt inspectate cu ajutorul instrumentelor de măsurare Mitsutoyo și al mașinilor de măsurat cu coordonate (CMM), care sunt etalonate periodic. Verificarea dublă asigură o calitate precisă și stabilă a produselor noastre. Fiecare componentă individuală poate fi urmărită și monitorizată în timpul prelucrării și asamblării.

Pingcheng oferă servicii complete pentru reductoarele pentru turbine eoliene. Expedierea produselor noastre reprezintă doar începutul parteneriatului nostru. Serviciul nostru clienți se concentrează pe asigurarea satisfacției dumneavoastră. De mai bine de 20 de ani oferim servicii de fabricație și am stabilit colaborări strânse cu companii japoneze de renume. Angajamentul Pingcheng față de prețurile corecte se bazează pe deceniile de experiență din domeniu și pe înțelegerea profundă a acestui sector. Analizăm desenele în programe speciale și vă prezentăm cea mai bună soluție la costuri accesibile, imediat după ce primim o cerere de ofertă.