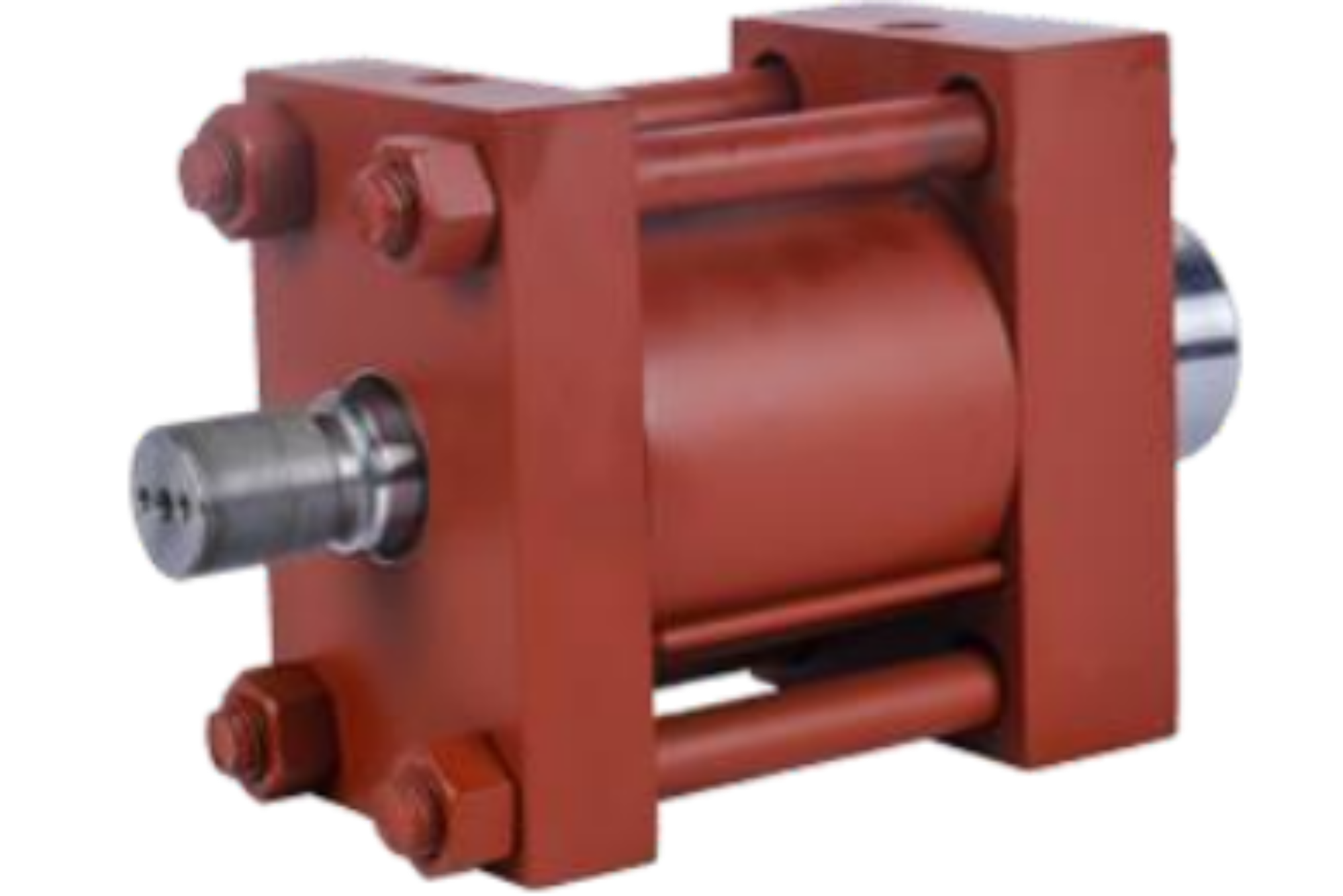

Как я всегда вам говорю о других статьях, одна из них касается того, что многие предприятия, заводы и компании могут использовать зажимные технологии формовки, например, производители автомобилей или игрушек. Но что такое зажимная форма? На самом деле это волшебное устройство, которое превращает материалы, такие как пластик или металл, в повседневные полезные предметы. Этот процесс называется литьем под давлением, и он имеет огромное значение в различных отраслях промышленности.

В течение многих лет пластик производился на заводах старым способом. Эти старые методы занимают много времени, и помимо этого они требуют значительных затрат. С помощью новой технологии зажимной формы заводы смогли выяснить, как они могут делать вещи гораздо быстрее и тратить меньше материалов. Автоматизированные зажимные формовочные машины созданы для производства большого количества отливок за меньшее время с улучшением точности, чего раньше не достигалось на производственных машинах.

Некоторые настолько сложны, что практически невозможно обработать их старым способом. Именно поэтому кастомная зажимная формовка может быть столь важной. Технология родом из твоего предложения: эта технология была разработана для производства объектов, для которых написание традиционными методами было бы совсем нерентабельным, а если писать (например, с использованием литья под давлением), то материал может не удовлетворять начальным допускам, точность пропорциональна дозировке. Эта новая система зажимной формовки позволяет делать измерения лучше — даже лучше, чем прочность и передача, обеспечивая надежную сборку пластиковых деталей до сих пор.

Это также экономит время и деньги для заводов, так как им больше не нужно использовать более одного оборудования для производства таких деталей. Однако они могут использовать одну специальную фиксирующую форму в процессе производства, которая идеально подойдет под их потребности. Это упрощает процесс производства, а также делает бизнес более эффективным, способствуя повышению качества продукции.

Штамповка металла: Штамповка металла — это вид обработки металла, при котором создаются различные формы из листового материала. Этот метод historically выполнялся с использованием мощных: больших простаивающих машин, что требовало значительных трудозатрат и времени. Единственными методами производства тогда были ковка или литье деталей, что занимало гораздо больше времени. 16 гвоздей, которые сейчас штампуются за минуту, стали возможны благодаря модификациям между технологией штамповки металла, особенно с применением технологии фиксирующей формы, что позволило литейным цехам создавать точно такие же высококачественные и прочные детали с использованием новых ковочных методов.

Производители продукции могут достичь глубины подгонки до третьего десятичного знака и большей точности деталей благодаря индивидуальным зажимным формам. Каждая из них идентична, что улучшает качество конечных результатов. В данной статье речь пойдет о отраслях, которые зависят от высококачественных, стабильных деталей для обеспечения того, чтобы их продукция работала так, как запланировано.

Линия транскрипции должна функционировать в полную силу, чтобы производственные площадки были наполнены деталями тогда, когда это необходимо. Это идеальное место для применения технологии зажимных форм. Заводы способны создавать индивидуальные зажимные формы для массового производства с быстротой и точностью. Эта точность — в сочетании с тем фактом, что практически нет отходов в процессе (в отличие от заводов, где просто отрезают ненужное, что также экономит деньги).

Приверженность компании Pingcheng честному ценообразованию основана на многолетнем опыте работы в отрасли и глубоких профессиональных знаниях. После получения вашего запроса на коммерческое предложение мы оперативно изучаем чертежи и проводим имитационное моделирование зажимной формы, чтобы предложить оптимальное решение с точки зрения стоимости.

Pingcheng — это производитель пресс-форм для зажимов и партнер по жизненному циклу изделий. Отгрузка нашей продукции — лишь начало наших партнерских отношений. Наша служба поддержки клиентов направлена на обеспечение вашего полного удовлетворения. Более 20 лет мы предоставляем услуги в области производства и выстроили тесное сотрудничество с известными японскими компаниями. Приверженность Pingcheng справедливым ценам основана на многолетнем опыте и глубоком понимании этой отрасли. После получения запроса на коммерческое предложение мы анализируем чертежи в передовой программной среде и предлагаем наиболее эффективное решение по наиболее обоснованной стоимости.

Pingcheng стремится помочь клиентам достичь их бизнес-целей за счёт наших решений в области цепочки поставок и пресс-форм для зажимов. Мы сосредоточены на том, чтобы помочь вам увеличить срок службы и потенциальную стоимость ваших изделий. PingCheng может стать надёжным производителем, которого вы ищете. Мы — проверенный партнёр, способный предоставить вам новые возможности.

Сегодня компания Pingcheng располагает более чем 20 производственными площадками и более чем набором пресс-форм для зажимов. Основная цель компании — обеспечение высокого качества продукции. Измерительные приборы Mitsutoyo и координатно-измерительные машины (КИМ) регулярно проходят калибровку. Двукратная проверка помогает поддерживать точность наших изделий и стабильность их характеристик. Каждый отдельный компонент может быть отслежен и контролируем на всех этапах механической обработки и сборки.