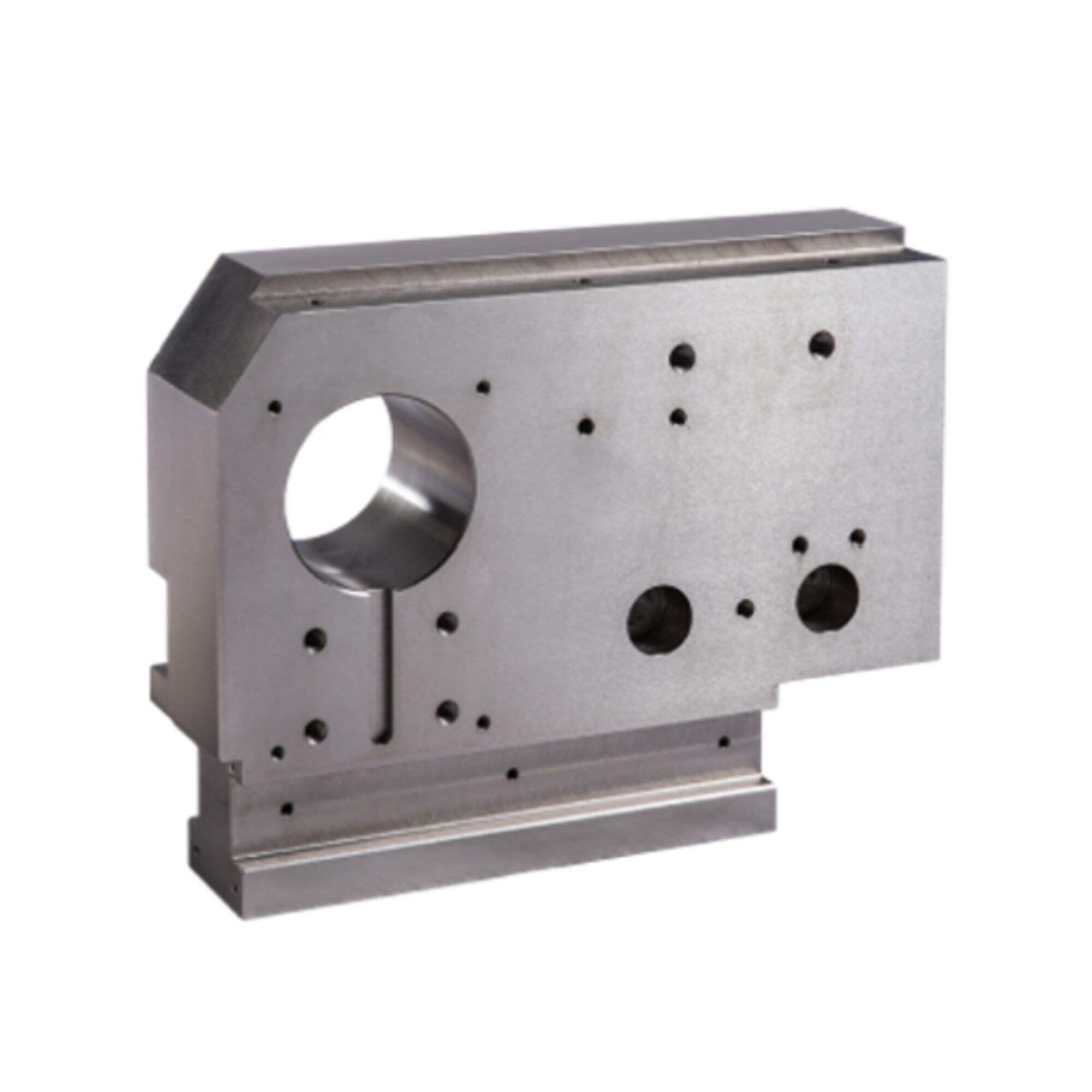

The bearing flange housing is an imperative thing to have for machines and they work well with this. It is the one that operates as a support for both of these bearings at their correct spinning order. It is composed of materials such as metal, plastic or composites.

Machines depend on bearing flange housing for supporting the bearings, reducing friction and cost of maintenance. These will have different types (2 cassette, 3 gear-jam or 4-bolt) of their respective standard sizes/hole spacings. The correct choice (of these method) depends on the weight of the machine and its running speed.

In short, these are the essential things to keep in mind while designing any machine bearing flange housing. The proper selection and protection of machines result in a longer shelf life with increased productivity.

Navigating the World of Bearing Flange Housing; An Integral Part in our Machinery Lacking in that all-important engineering backbone, machines would be unable to fulfill their purpose safely. Bearing Flange Housing is an important part of bearing which supports and facilitates the rotation load of bearings to run efficient when industrial equipment work.

Bearing flange housing: Bearing flange housings are a very important aspect of the industrial applications where they take part in reducing friction and service cost by supporting as well aligning bearings efficient way. Bearing flange housings are also available in the 2-bolt, 3-bolt and four bolt variations that come is a multitude of size shapes, and materials. Determining the right style of bearing flange housing depends on factors such as load capacity, speed requirements and environmental conditions within a machine.

Proper maintenance and bearing flange housing repair is essential in that it guarantees efficiency of machinery, and saves the machine from unwanted down time. Read below for principal maintenance and repair plans

In summary, bearing flange housing is an important part in industrial machinery to support bearings and reduce friction and maintenance costs. When bearing flange housing is chosen correctly and maintained properly, it ensures a higher machine performance operation for more time. Adoption of Next Gen housing designs will bring about machines that are more agile, dependable and easier to support.

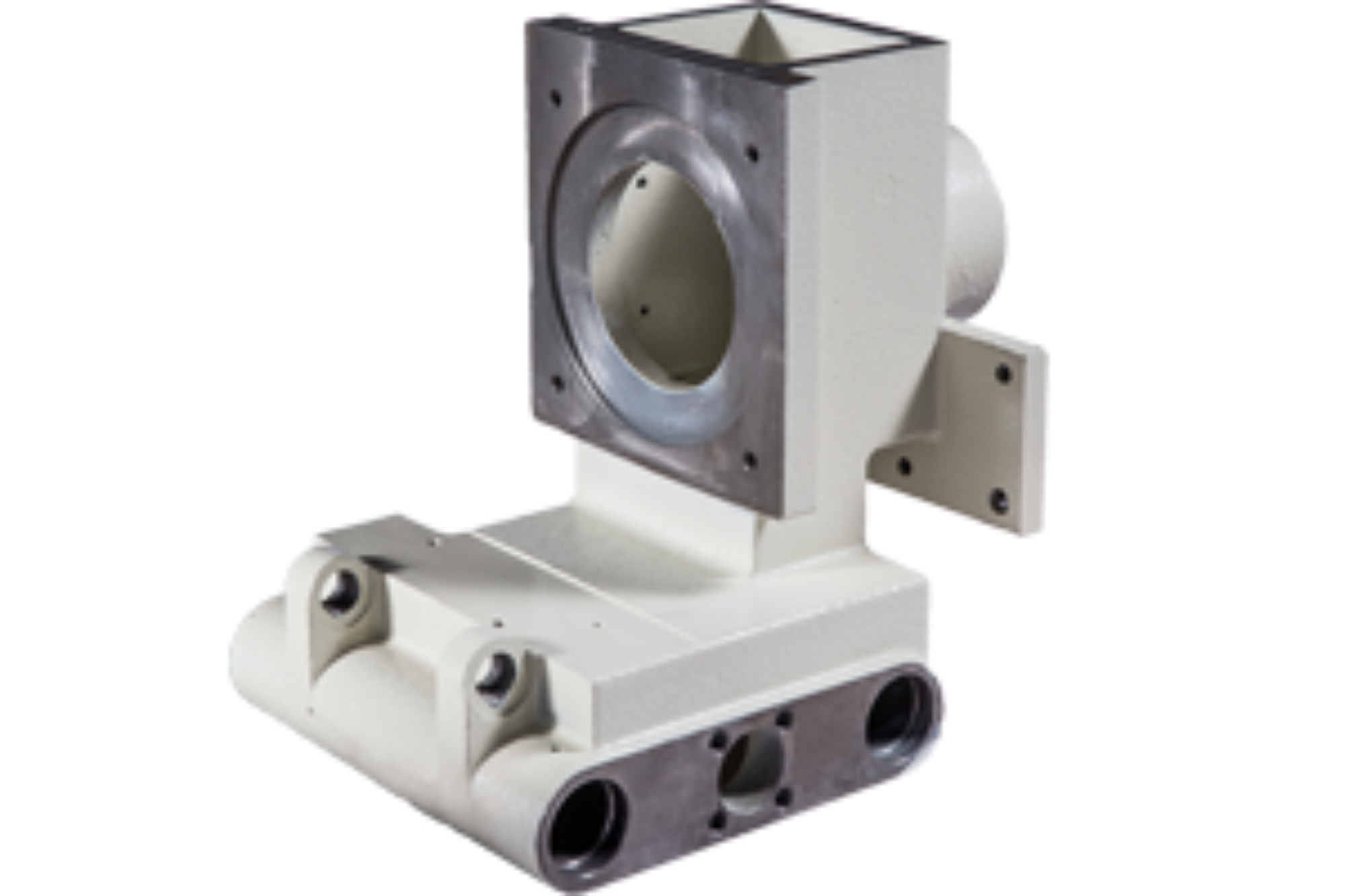

Based on bearing flange housing and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng is committed to helping customers realize their business goals through our supply chain and bearing flange housing. We concentrate on helping you increase the lifespan and potential value of your products. PingCheng can be the reliable manufacturer that you need. We are a trustworthy partner that can provide opportunities.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They bearing flange housing. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with bearing flange housing for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.