Các đầu trục giao của Pingcheng là một thành phần rất quan trọng cho máy bơm tãng động. Những máy bơm này擅长 nâng và bơm các chất lỏng như nước hoặc dầu. bình tích áp của một giếng nước hoặc giàn khoan dầu: đây là những máy bơm hoạt động để di chuyển các chất lỏng đó lên và ra khỏi độ sâu. Tuy nhiên, nếu không có thanh gối trượt, máy bơm sẽ không thể hoạt động đúng cách và chúng ta cần di chuyển những chất lỏng đó! Hôm nay, chúng ta sẽ tìm hiểu thêm về cách thanh gối trượt đóng góp vào việc đảm bảo máy bơm hoạt động hiệu quả. Máy bơm tịnh tiến là một máy móc trong đó chất lỏng hoặc khí được đẩy về phía trước bằng piston và hút ngược lại thông qua van hút sao cho nó hoạt động định kỳ. Hãy tưởng tượng nó giống như một chiếc bơm xe đạp mà bạn sử dụng để bơm căng lốp. Mặt khác, máy bơm tịnh tiến rất lớn, mạnh mẽ và bền bỉ, có thể được sử dụng cho các công việc nặng. Khả năng bơm chất lỏng đòi hỏi phải sử dụng thanh gối trượt này khi các máy bơm được chế tạo.

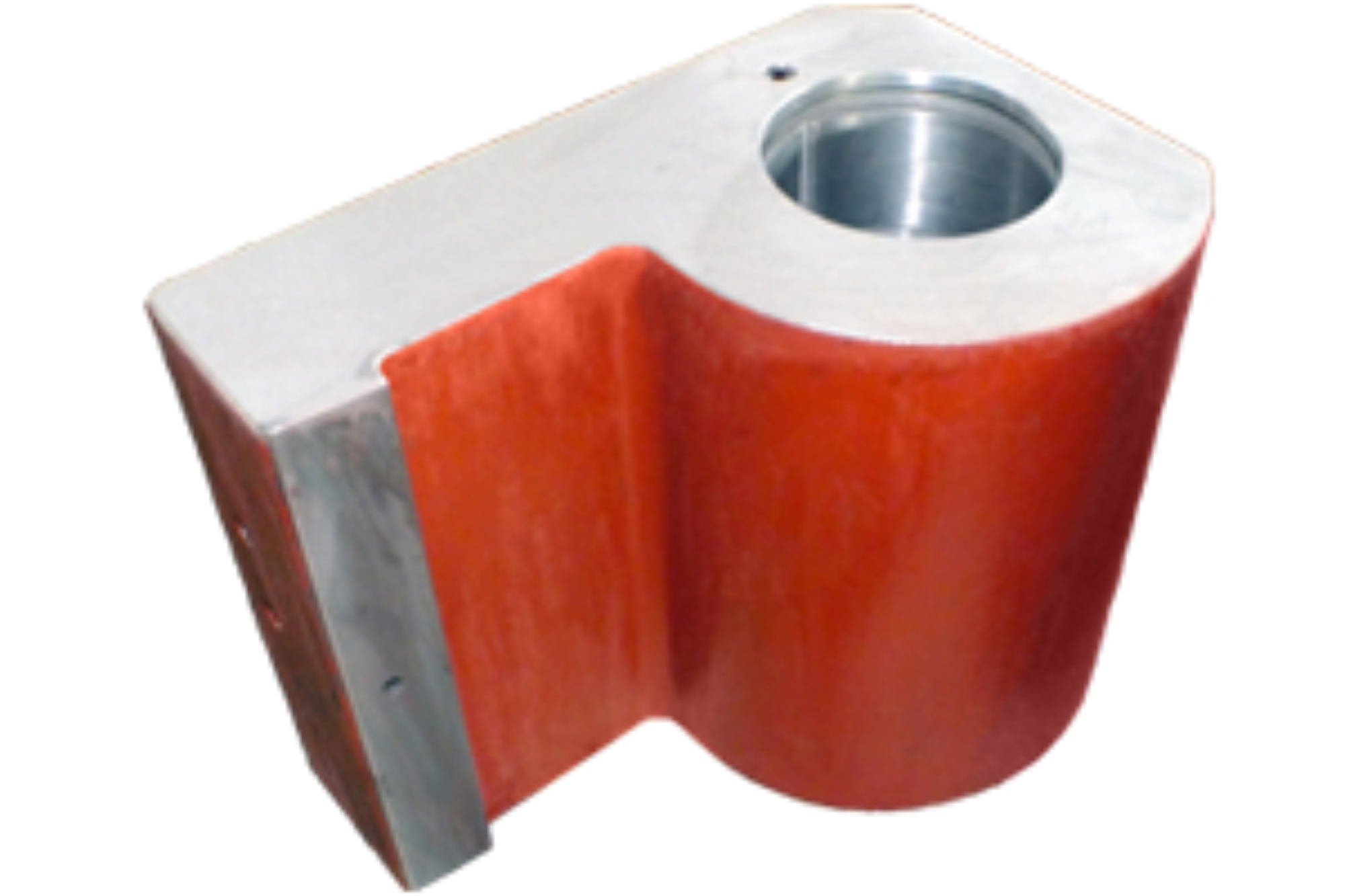

Ty nổ của Pingcheng ở trên một phần được gọi là piston. Nó kết nối piston với một bộ phận quan trọng khác được gọi là trục khuỷu. Khi piston di chuyển lên xuống, ty nổ cũng di chuyển theo. Nếu piston di chuyển lên xuống trong lỗ xi-lanh, thì chuyển động đó sẽ truyền năng lượng từ piston đến trục khuỷu. Trục khuỷu sau đó hoạt động bằng cách điều khiển van của bơm nước hoặc dầu, điều này là cần thiết để cho chất lỏng chảy qua các bơm này. Bơm sẽ không hoạt động và thực hiện chức năng của nó nếu không có quá trình này. Ty nổ rất mạnh mẽ và bền bỉ, làm cho bơm hoạt động hiệu quả hơn. bộ tích nhiệt áp suất cao có thể xảy ra ngay cả với một số thanh chéo được làm từ thép cứng hoặc gốm. Những vật liệu này rất bền và tốt hơn nhiều so với các loại khác như đồng thau hoặc nhôm, có thể mòn nhanh chóng. Với những vật liệu bền bỉ hơn này, bơm có thể được thiết kế để hoạt động tốt hơn và kéo dài tuổi thọ hơn.

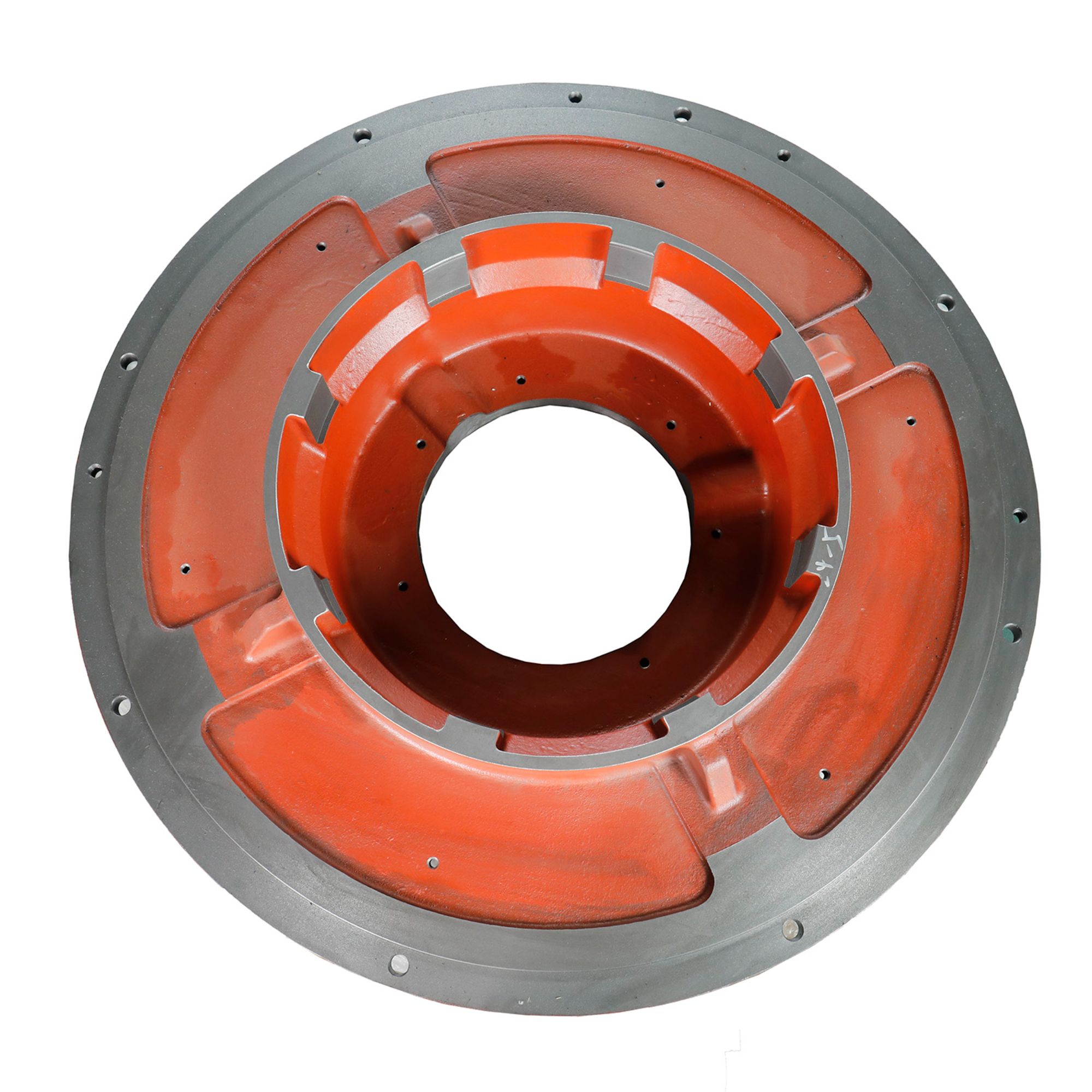

Hệ thống thanh chéo của Pingcheng đóng vai trò quan trọng trong nhiều lĩnh vực khác nhau, chẳng hạn như khai thác dầu khí, chế biến hóa chất hoặc xử lý nước. tích áp thủy tại một số địa điểm này, các máy bơm phải có khả năng vận hành liên tục 24/7 trong thời gian dài và trong môi trường khắc nghiệt. Do đó, việc hệ thống thanh chéo có độ bền cao và khả năng chống mài mòn tốt là vô cùng quan trọng.

Các nhà sản xuất thực hiện quy trình xây dựng và sản xuất chi tiết, sử dụng những vật liệu tốt nhất để đảm bảo hệ thống thanh chéo có độ bền cao. bộ tích năng hơi nước có tác dụng giảm thiểu thiệt hại xảy ra trên các bộ phận này. Ngoài ra, hệ thống trục giao được thiết kế sao cho có thể thay thế một cách dễ dàng. Đây là một tính năng tuyệt vời vì nếu một bộ phận bị hỏng hoặc cần thay thế, nó có thể tiết kiệm tiền và thời gian trong việc sửa chữa xe của bạn.

Điều này đặc biệt hữu ích vì bôi trơn giúp ngăn ngừa bất kỳ tiếp xúc nào giữa piston và thành xi-lanh tương ứng. Bôi trơn đúng cách làm giảm ma sát, từ đó giúp bơm hoạt động hiệu quả hơn và kéo dài tuổi thọ. Có nhiều phương pháp bôi trơn đầu nối chéo (crosshead), bao gồm bôi trơn bằng dầu, bằng mỡ và thậm chí cả bôi trơn khô. máy ép nhựa dọc Loại phương pháp bôi trơn được sử dụng sẽ được xác định dựa trên cách máy bơm được vận hành và môi trường xung quanh nó.

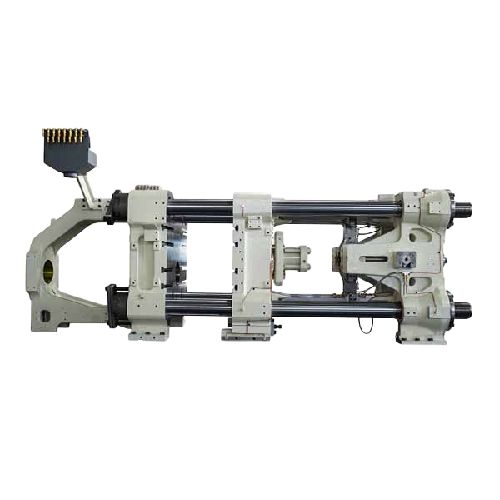

Dịch vụ khách hàng của chúng tôi tập trung vào sự hài lòng của quý khách. Trong hơn 20 năm qua, chúng tôi đã cung cấp các đầu trượt và xây dựng mối hợp tác bền vững với nhiều doanh nghiệp Nhật Bản nổi tiếng trong ngành. Dựa trên kinh nghiệm dày dặn cùng sự am hiểu sâu sắc về ngành, Pingcheng cam kết mang đến cho khách hàng mức giá minh bạch và công bằng. Ngay khi nhận được yêu cầu báo giá, chúng tôi sẽ rà soát bản vẽ bằng phần mềm chuyên dụng và đề xuất giải pháp tối ưu nhất với chi phí hợp lý nhất.

Pingcheng cam kết hỗ trợ khách hàng hiện thực hóa các mục tiêu kinh doanh thông qua chuỗi cung ứng và đầu nối chéo (Crosshead) của chúng tôi. Chúng tôi tập trung vào việc giúp quý khách nâng cao tuổi thọ và giá trị tiềm năng của sản phẩm. Pingcheng có thể trở thành nhà sản xuất đáng tin cậy mà quý khách cần. Chúng tôi là đối tác uy tín, sẵn sàng mang đến những cơ hội hợp tác.

Dựa trên Crosshead và sự hiểu biết sâu sắc về kinh doanh, Pingcheng cam kết cung cấp cho khách hàng giá cả hợp lý. Khi nhận được yêu cầu báo giá, chúng tôi xem xét bản vẽ và mô phỏng bằng phần mềm đặc biệt ngay lập tức, và đưa ra các giải pháp hiệu quả nhất với chi phí công bằng.

Hiện nay, Pingcheng sở hữu dây chuyền sản xuất đầu nối chéo (Crosshead) cùng 50 kỹ thuật viên lành nghề. Đội ngũ này nỗ lực không ngừng nhằm đảm bảo chất lượng sản phẩm ở mức cao nhất. Sau đó, sản phẩm được kiểm tra bằng các thiết bị đo lường của hãng Mitutoyo và máy đo tọa độ ba chiều (CMM), cả hai đều được hiệu chuẩn định kỳ. Việc kiểm tra kép này giúp duy trì độ tin cậy và độ chính xác cao trong kiểm soát chất lượng. Quá trình gia công và lắp ráp các chi tiết quan trọng được kiểm soát chặt chẽ và truy xuất được nguồn gốc.