Bạn có từng quan sát một thiết bị di chuyển qua lại hoặc lên xuống không? Một xi lanh piston - một thành phần đặc biệt của máy móc làm cho loại chuyển động này trở nên khả thi. Xi lanh đẩy là một thiết bị bắt buộc cho phép kẹp đẩy hoặc kéo lên xuống. Như ta thấy, trong xi lanh của nó có một piston bên trong và một ống nón đang di chuyển. Piston, thứ rất nặng, có thể đẩy hoặc kéo bằng chuyển động của piston và do đó ít nhất làm công việc này dễ dàng hơn cho máy móc.

Bộ phận xy-lanh piston Xy-lanh piston rất hữu ích để di chuyển các vật nặng theo chuyển động thẳng hàng (ray) hoặc lên/xuống. Dưới đây là một số nơi phổ biến mà bạn có thể gặp phải xy-lanh piston - trong các nhà máy sản xuất hàng hóa hoặc tại các công trường xây dựng trước khi tòa nhà trở nên hoạt động và trong quá trình vận chuyển vật liệu giữa các nhà máy khác nhau. Chúng giúp máy móc hoạt động nhanh hơn và hiệu quả hơn, điều này cơ bản là giảm thời gian đưa sản phẩm ra thị trường. Các piston xy-lanh trước đây thường khá lớn, và đó là một điều tốt vì bạn đang mang trọng lượng dọc theo đường ray.

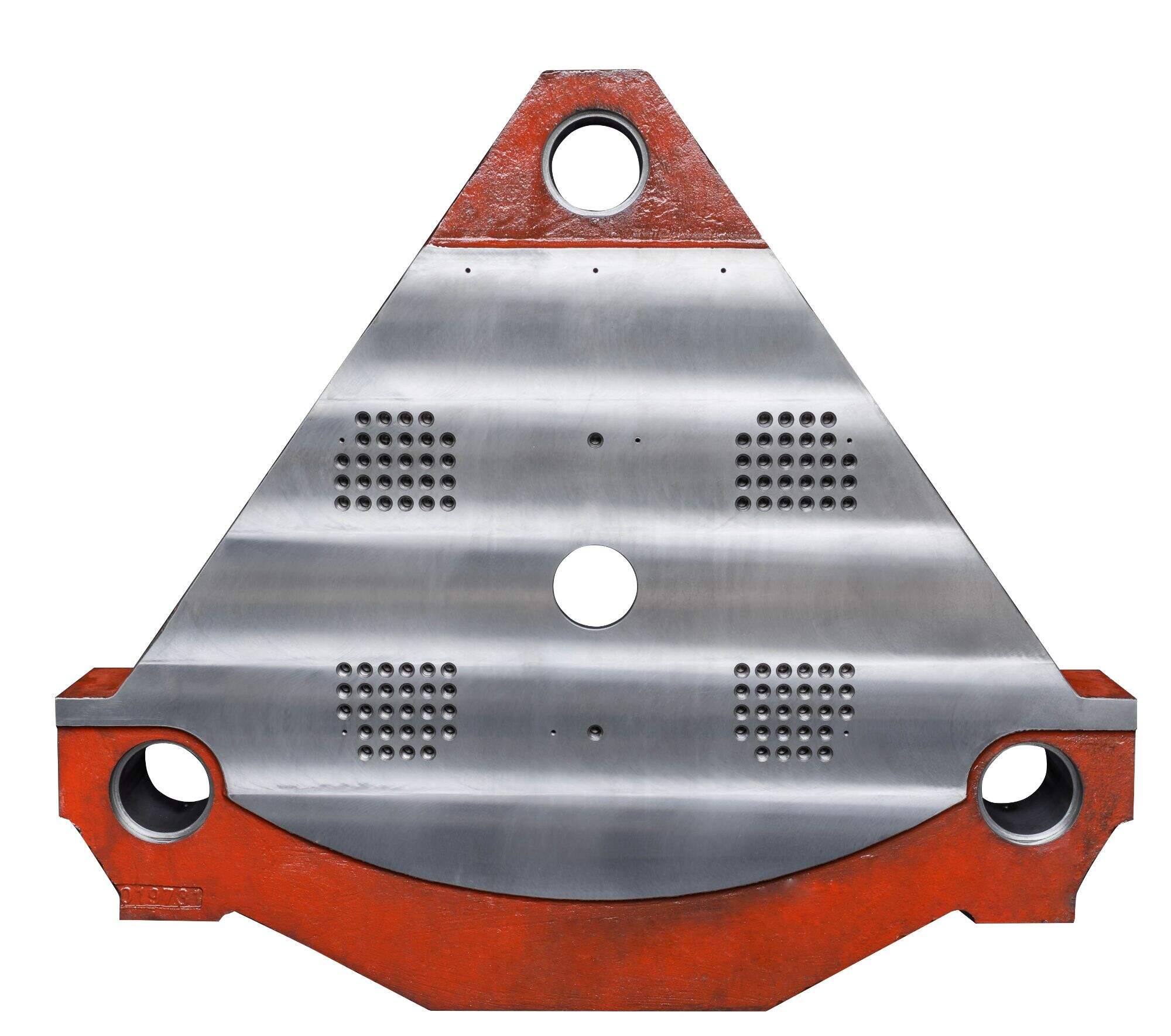

Mô tả Xi lanh đột quỵ là một actuator khí nén hoặc thuỷ lực tạo ra chuyển động tuyến tính được kiểm soát của thanh (chuyển động sẽ phụ thuộc vào các lực tác động lên piston).

Điều này cực kỳ quan trọng, đặc biệt là đối với chuyển động máy được kiểm soát. Đó là nơi các xi lanh hành trình phát huy tác dụng. Ngoài ra, các xi lanh có hành trình còn giúp cung cấp sự kiểm soát chính xác về tốc độ và hướng di chuyển của máy. Nhờ vậy, máy có thể bắt đầu lại với một trong những cách tiếp cận này và đủ nhanh để đến nơi cần đến mà không quá chậm hoặc không đủ nhanh. Xi lanh hành trình rất hữu ích trong hoạt động chung của máy móc vì chúng quản lý chuyển động. Chính tính chất liền mạch này khiến hệ thống cảm thấy ít rủi ro hơn, không chỉ giảm thiểu bất kỳ tổn hại nào cho chính nó mà còn đảm bảo rằng không có tải nặng nào bị vận chuyển sẽ rơi vào tình trạng không an toàn.

Với nhiều loại chiều dài piston khác nhau, điều này làm cho mỗi loại trở nên độc đáo. Việc chọn loại piston phù hợp là rất cần thiết cho mọi nhu cầu của bạn. Có nhiều yếu tố cần cân nhắc khi chọn piston nhưng có một số điểm quan trọng mà bạn nên xem xét trước khi đưa ra quyết định cuối cùng. Tốc độ máy móc là yếu tố thứ hai - Hãy cân nhắc kích thước và trọng lượng của vật bạn sẽ nâng. Và, cần bao nhiêu lực để di chuyển tải đó? Ví dụ, trong một số piston chỉ có piston di chuyển về một phía và quay lại, trong khi những piston khác có thể di chuyển hai chiều. Các bước cần thực hiện:- Chọn loại piston phù hợp để vận hành máy móc của bạn một cách hiệu quả.

Mỗi máy móc đều cần bảo trì định kỳ để tiếp tục hoạt động đúng cách, bao gồm cả xi lanh piston. Do đó, bạn sẽ phải bảo dưỡng nó đúng cách; vì ngay cả một chút bụi bẩn cũng có thể làm hỏng tai của bạn! Bạn cũng cần thêm dầu để đảm bảo các bộ phận được bôi trơn tốt và không có mài mòn hoặc hư hại quá mức theo thời gian. Khi làm việc với xi lanh piston dài, bạn cần sử dụng loại chất lỏng phù hợp - dù đó là dầu thủy lực hay khí nén. Nói chung, sự vận hành liên tục của trục sẽ kéo dài hơn và hoạt động tốt hơn nếu bạn duy trì bảo dưỡng xi lanh piston thường xuyên.

Dựa trên xi-lanh hành trình và kiến thức chuyên sâu về lĩnh vực kinh doanh, Pingcheng cam kết mang đến cho khách hàng mức giá minh bạch và trung thực. Chúng tôi phân tích bản vẽ, tái tạo lại bản vẽ bằng phần mềm chuyên dụng, sau đó đưa ra mức giá tốt nhất.

Dịch vụ khách hàng của chúng tôi luôn lấy sự hài lòng của quý khách làm trọng tâm. Trong hơn một thập kỷ qua, chúng tôi đã cung cấp các dịch vụ gia công cơ khí và xi-lanh hành trình cho nhiều công ty Nhật Bản nổi tiếng. Chính sách báo giá trung thực của Pingcheng được xây dựng dựa trên kinh nghiệm dày dặn trong ngành và hiểu biết sâu sắc về lĩnh vực này. Ngay khi nhận được yêu cầu báo giá, chúng tôi sẽ phân tích bản vẽ bằng phần mềm chuyên dụng và đề xuất giải pháp tối ưu với chi phí hợp lý.

Hôm nay, Pingcheng sở hữu hơn 20 cơ sở sản xuất và hơn thế nữa về xi-lanh hành trình. Mục tiêu của công ty là cung cấp sản phẩm chất lượng cao. Các thiết bị đo lường và máy đo tọa độ ba chiều (CMM) của hãng Mitutoyo được hiệu chuẩn định kỳ. Việc kiểm tra kép giúp duy trì độ chính xác của sản phẩm và tính ổn định. Mỗi chi tiết đơn lẻ đều có thể truy xuất nguồn gốc và giám sát trong suốt quá trình gia công và lắp ráp.

Pingcheng cam kết hỗ trợ khách hàng về xi-lanh hành trình thông qua chuỗi cung ứng và giải pháp dịch vụ của chúng tôi. Chúng tôi nỗ lực giúp quý khách kéo dài tuổi thọ và tối đa hóa giá trị sản phẩm. PingCheng là nhà sản xuất đáng tin cậy mà quý khách đang tìm kiếm. Chúng tôi là một doanh nghiệp mang tiềm năng thực sự.