The Toy Factory Small Machine is very key Just a machine that collects some special material and forms it into all the little things children love to play with. One of the most crucial developments in toys, and this is part of process called -Injection molding.csrf- (more on Injection molded parts later). There are a lot of different parts at play to allow this, but most importantly is what's called the clamping unit.

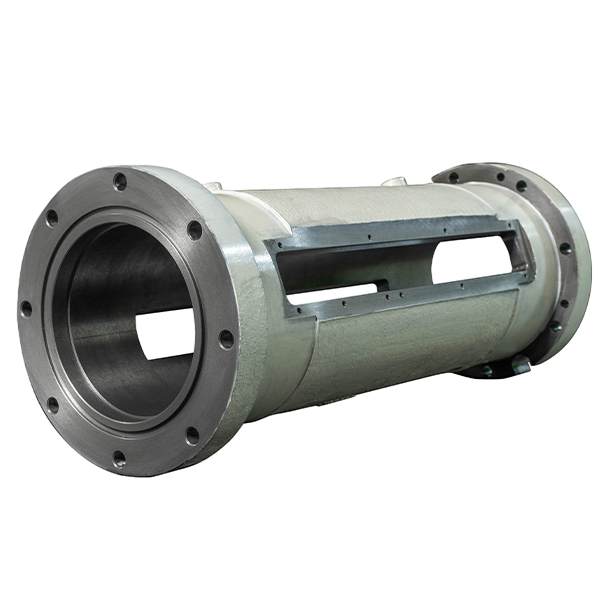

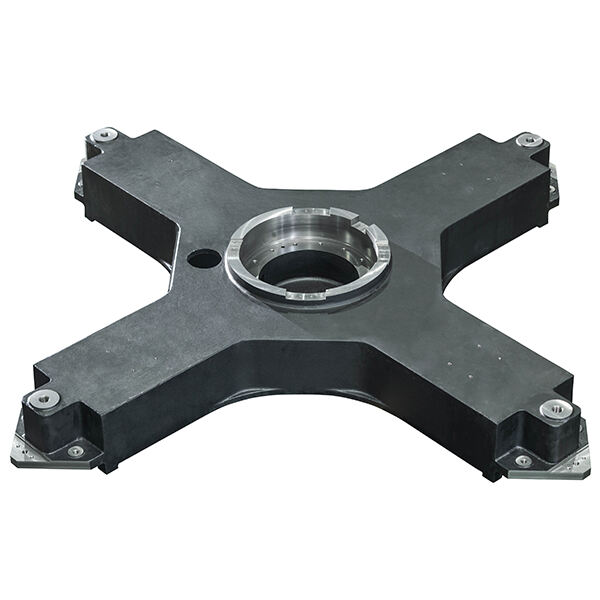

Clamping unit is a unique division of the machine that imitates as big hand. It keeps two halves of a mold tightly pressed together as the special material is injected inside. The mold consists of two pieces that easily come apart like a jigsaw puzzle piece. The clamping unit, however, holds these two halves together keeping them from falling apart on you. This is important because when the mold closes, this hugging action prevents material from getting trapped in or around it.

A tight clamping of the mold pieces ensures that no material is leaked throughout. The clamping is also the power of that grip (in tones) and this eventually tells you how big something. Think what would happen if you were to squeeze the plush toy really hard in your hand such that it took a different shape. The clamping force makes it possible so the material will then take its proper shape in such a mold. Without significant clamping force, it could let the material escape from which would destroy a toy.

The clamping force is very important. If the clamping force it too low such a thing can occur as well, and your toy will be ruined before even leaving production line. Conversely, if the force is too strong it will break through mould or cause wasting more energy. That is why applying the correct volume of clamping power an automobile workshop should useRelativeToForce. The correct pressure is used to make sure that everything comes together properly and high quality toys are made both efficiently and safely.

Over time the machines for injection molding have gotten better and better due to advancements in technology. It was clamping units using so called hydraulic power with highly variable parameters. This means the machine parts are moved using a liquid rather than electricity. Electric power is required for other clamping units that are mentioned and it also more energy saving. And now, there is even a new clamping unit available that utilizes the magic of magnets to keep the mold pieces in contact instead nuts-and-bolts sod heavy metal. These improvements assist to the equipment run a lot better and in addition support manufacturing of toys more quickly with accuracy.

During Operation Clamping-unit problems sometimes). If the mold pieces do not mate well, for example, perhaps the clamping force needs adjusting or altered. Else if the mold does not open and close properly, then there should be some mis-awareness in its clamping mechanism. To explain all of the exact points and how they affect it can be a lengthy post, but simply said this means that by fixing those issues in injection molding process you prevent stoppages from happening thus ensuring toys to me molded without delays.

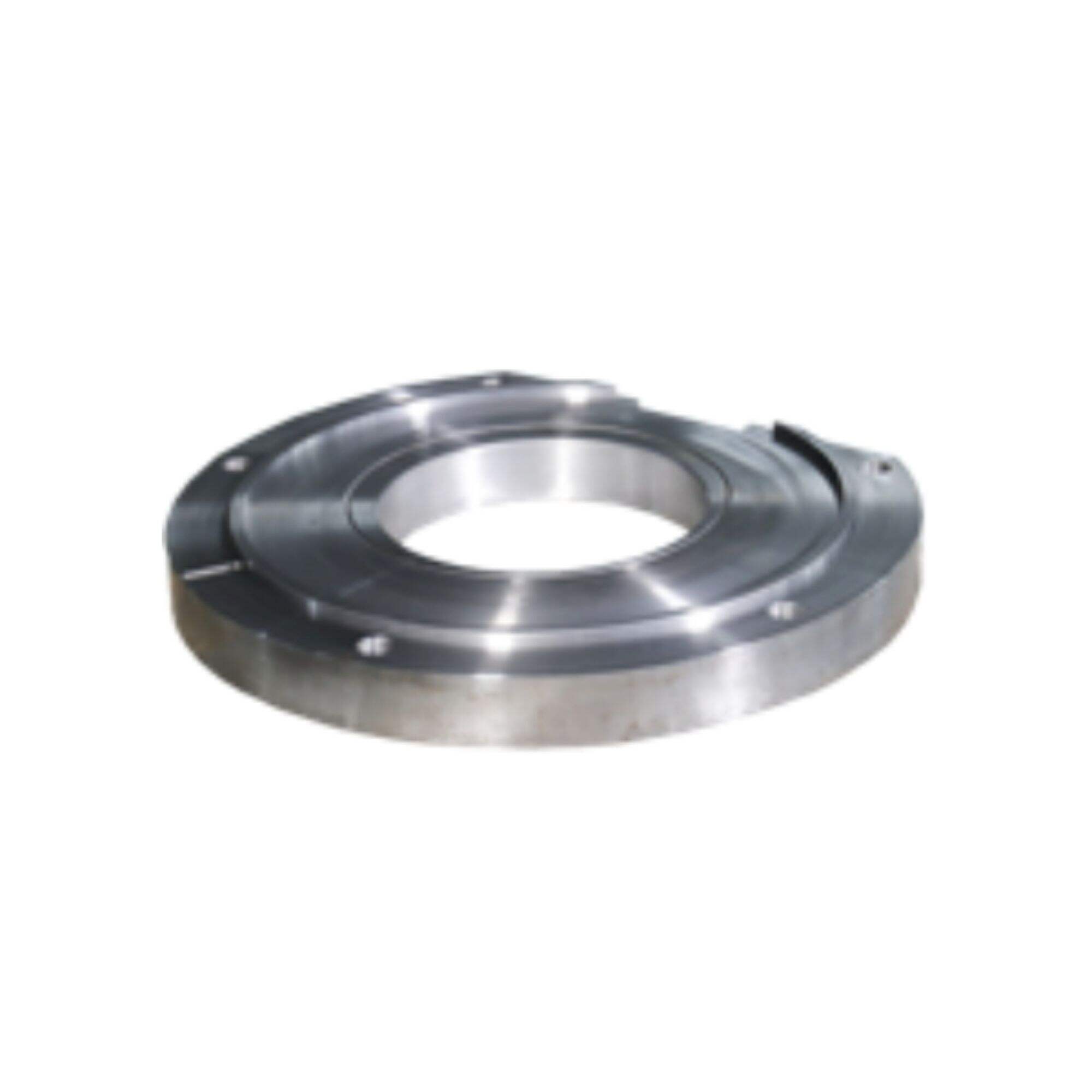

Pingcheng now clamping unit injection molding and 50 highly skilled technical employees. They strives to provides high quality. Then, the products is inspected by Mitsutoyo measuring instruments and CMM that periodically calibrated. The double-checking keeps quality reliable and accurate. The machining and assembly of important parts controlled and traceable.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and clamping unit injection molding with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We clamping unit injection molding, recreate it in specialized software, and then provide the most competitive price.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We clamping unit injection molding as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.