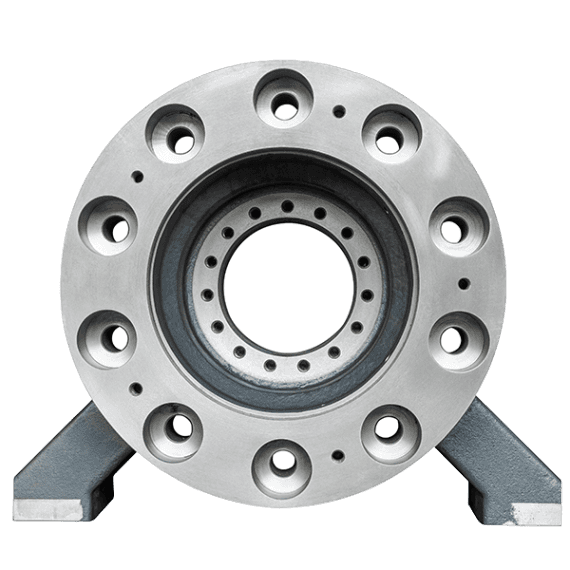

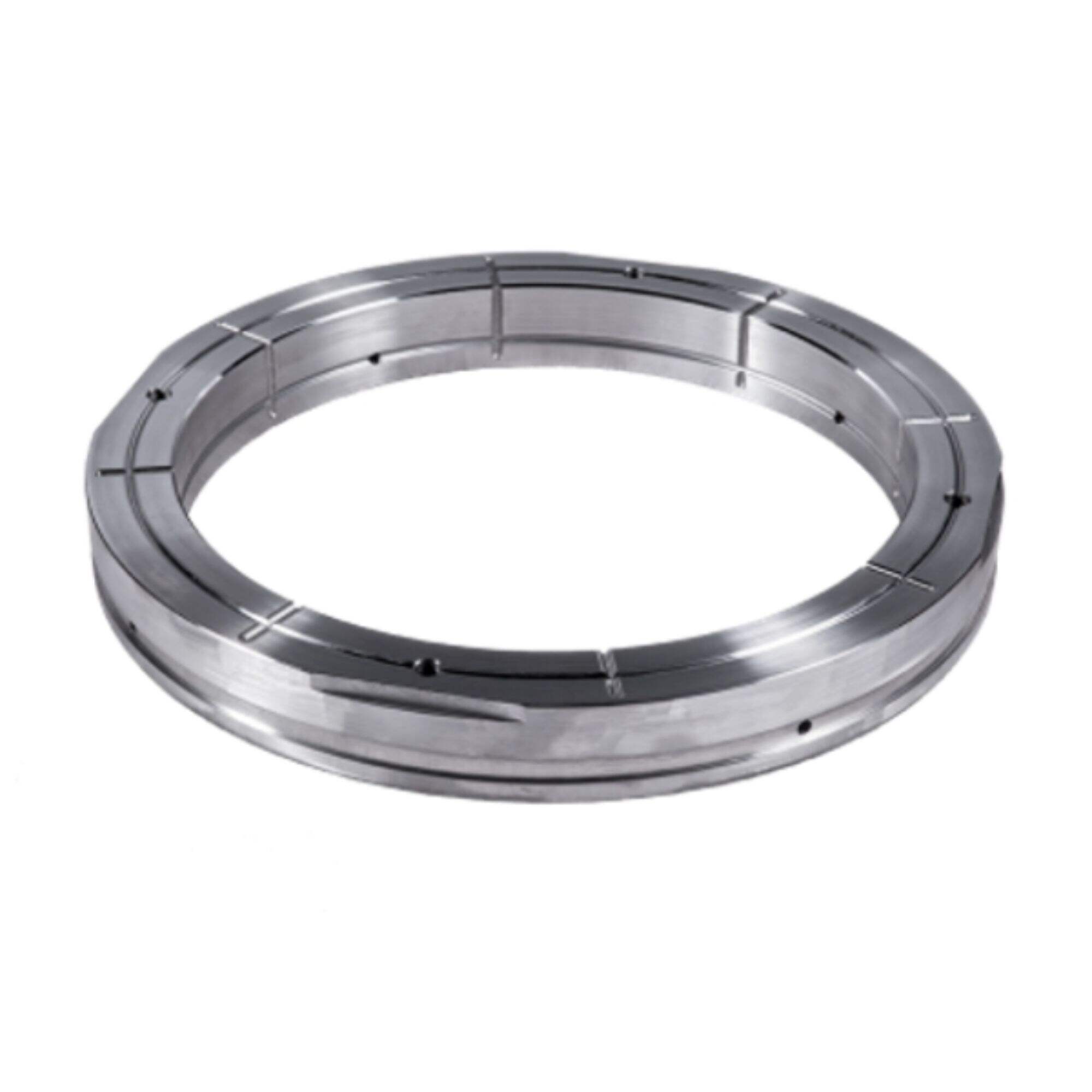

In metalworking, Assembly die clamps are one of the most important tools. They help lubricate things for a tight fit so metal can get bent and cut just right. Our firm, Pingcheng, produces the very best die clamps around. We ensure our clamps are easy to work with, have a longer lifespan, and assist workers do their jobs better, faster. Now let us get into some fun about Pingcheng and it's die clamps!

The die clamps of Pingcheng are the best because it would help meet the metal parts with great accuracy. That is, that everything comes out 100 per cent neat, in its proper place. With the help of these clamps, workers can keep things stable, making their task much easier and faster. This allows factories to hum along, producing plentiful high-quality metal products.

Industrial design for maximum service life What's in The Box 3.34 Joules 1-1/4-Inch SDS Plus Rotary Hammer Owner's Manual Warranty 1-Year Satisfaction Guaranteed Specifications Sku RH328V-RT Brand Bosch Amperage 7.4 Length 17.8 inch Width 11 inch includes (1) - 3605438513- SPRING LOADED BALL (1) - 1609100219- SERVICE PACK(see web page for customer service) Max.

Our die clamps are really built to last. They must be, because they toil in tough conditions while a load of heavy, hard metal is being thrown around and hammered into shape. Pingcheng ensures that each clamp is durable and long lasting, even with heavy use throughout every day. This spares factories the trouble of constantly restocking clamps, and saves them money, too.

The neat thing about Pingcheng’s die clamps is that they can be employed for a variety of machinery. Whether it is a huge industrial press or a little machine, our clamps can work with it. It’s a terrific convenience for craftspeople who can rely on a single, dependable tool for an assortment of tasks, which contributes to order and speed in their workspaces.

No one wants to do battle with a difficult-to-use tool, right? Then you can purchase with ease, the die clamps are easy to use from Pingcheng! The soles can be adjusted easily and taken on and off without bothering the user to fiddle with adjusting their tools. This overall speeds up the entire metalworking process and lessens the strain on workers so they can work more efficiently and let out their best work.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate die clamps as soon as we can, and provide the best solution for your cost.

Pingcheng is dedicated to helping customers die clamps by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They die clamps. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.

Pingcheng is a full-service and die clamps. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.