Horizontal Injection Moulding Machine World

Curious about the awesome horizontal injection machines? These machines are what help create everything from our favorite toys to parts required in manufacturing making for cars or life saving medical equipment. So stick around as we take a look into the inner workings of these amazing electric injection from Pingcheng and really see how they work.

There are so many advantages of horizontal injection molding due to which it is popular in manufacturing industry. The speed at which these hydraulic molding machine from Pingcheng operate is one of the biggest advantages. If they are using a larger mold, the injection capacity for horizontal machines is also higher and can produce multiple products simultaneously. This effectiveness is generally essential when the very same goods are needed on a good scale in an exceedingly short time period.

It was the development of horizontal injection molding equipment that changed how plastic products were made forever. Before their introduction, the process of fully automatic vertical injection moulding machine from Pingcheng was extremely arduous and time-consuming, usually done by hand. But with the paradigm shift in production capability brought now innovation of horizontal machines. All of a sudden, millions of things could be made for pennies on the dollar that had never been possible before-and unleashing an entire world where consumers yearning plastic items are concerned.

Horizontal injection machines are also able to improve the use of material, and minimize waste in some important cases. At the time of injection, these high speed vertical injection molding machine make it possible for manufacturers to carefully control how much plastic is being injected so that they are not wasting excess and their carbon footprint in the process. This is not only good for the planet, but clearly cost-effective as well to organisations-a win-win proposition.

Horizontal machines are versatile and, therefore, the best option for mass production where your need is to produce a large number of identical items. For thousands of car bumpers, or toy trucks, etc., these machines are very good at churning out what high-volume manufacturing needs. Just think because the next time you see a plastic part or component such as in a medical device to an aircraft, chances are that they were made on this simple horizontal injection mold machining.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate Horizontal injection molding machine as soon as we can, and provide the best solution for your cost.

Our customer service focuses on your satisfactions. We have been offering an Horizontal injection molding machine and developing a strong cooperation with industry well-known Japanese enterprises for over 20 years. Based on decades experience and comprehensions of this industry, Pingcheng is dedicated to offering our customers honest prices. We review the drawing using specialized software and provide most effective solutions at the most reasonable cost the moment we receives an inquiry for a quotes.

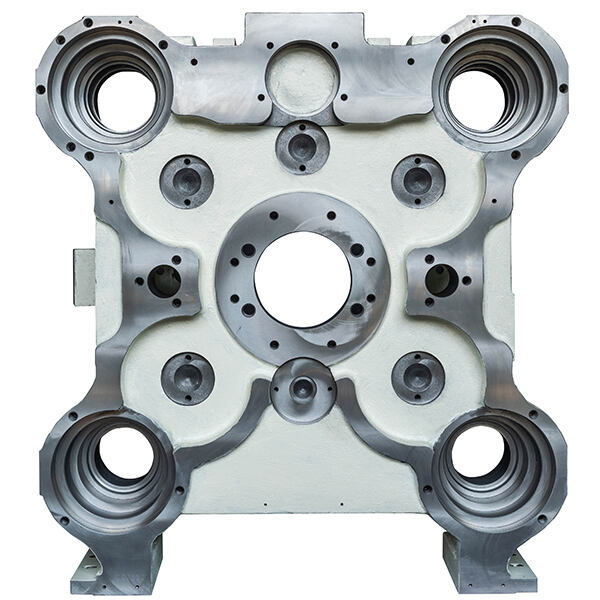

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They Horizontal injection molding machine. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.

Pingcheng is dedicated to helping customers Horizontal injection molding machine by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.