Injection mold clamps are tools that must be considered when producing plastic parts. These work to hold together two pieces of a mold very tightly. This is important because the hot molten plastic has to flow into that shape appropriately filling up space in the mold. Otherwise, the mold was not held secure and all of that expensive liquid plastic would have poured out. The Injection Mould Clamps are of many kinds, each element have the proper functions in molding a plastic product efficiently and correctly.

Plastic products are generally produced using injection mold clamps because they have a very important priority. They close the mold tightly so no liquid plastic leaks out. Without those clamps, the liquid plastic would run everywhere instead of forming the correct shape and result in materials being wasted as well time. The clamps also help in the proper placement of plastic into mold. If the plastic does not fill evenly, your end product may look weird or have defects; you do not want that. That is the problem for what clamps are of great use in plastic item manufacturing.

Injection mold clamps are also designed to lock and keep the two halves together, forcing each item created out of plastic in order that they will be uniform. The mold is left in the same location, and so a channel for plastic must be added each cycle. Consistency is key since it can prevent errors and guarantee everything looks good as well. In fact, without the clamps this would probably be impossible to achieve in such a consistent and high quality scale throughout all the products being made hustle.

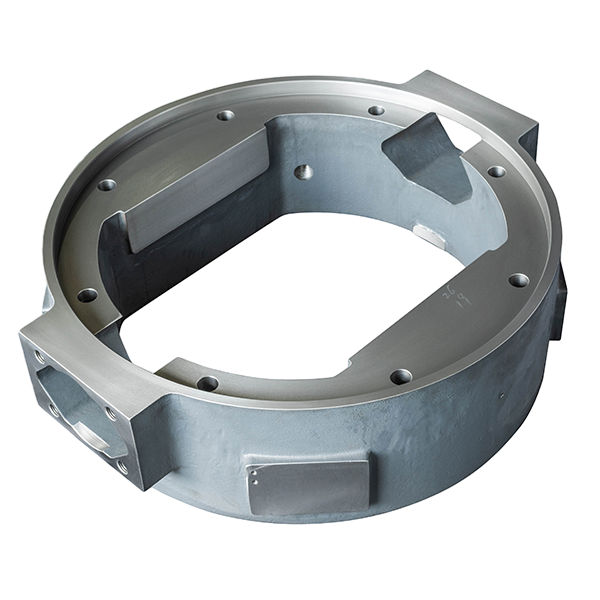

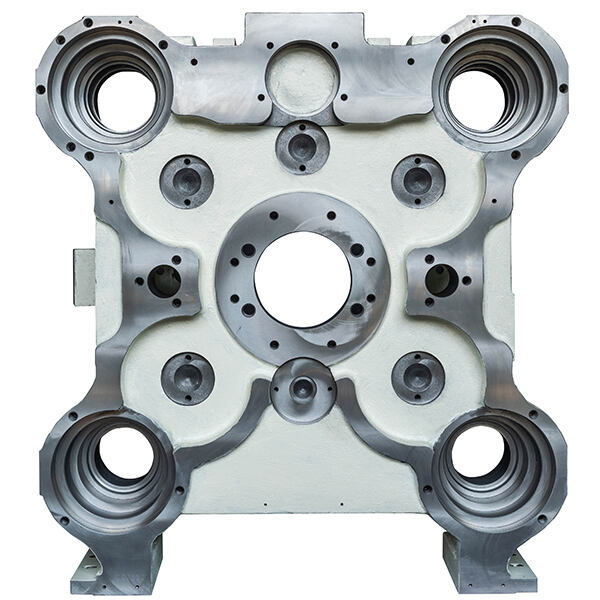

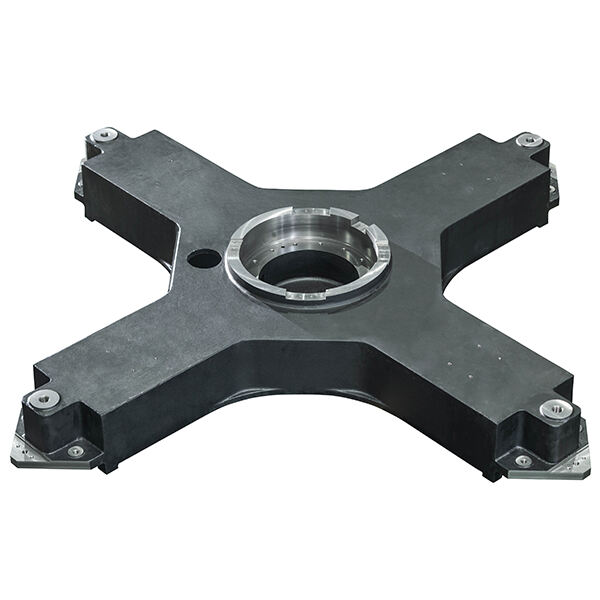

Different mold clamps have different structures. Mechanical clamps, which would be in the class of some others that use working a rod and plate to keep the mould protected Hydraulic clamps, on the other hand, use pressure to tighten the mold together for a more robust hold. Moreover, magnetic clamps (which employ magnets to hold the mold together) are used. Fast-installation clamps are convenient to install, can be opened quickly and fastened when applied. In addition, air-powered clamps secure the mold via compressed air. The manufacturer would know which of the specific clamps to choose for a particular task, as one type of clamp has it's designated area where is stands out best in use.

Injection mold clamps should be properly maintained to guarantee they function well. Clean and well-maintained, they can become brittle or seize if left unused for long periods of time. Such a situation can lead to serious trouble and the creation of faulty plastic products, which is very expensive to correct. This would make sure your current piping is sitting right straight and you may possess as well maintained the appropriate clamps; cleaned all of them on regular basis, examined occasionally for almost just about any damages plus replaced often the weakened kinds immediately. These steps will help ensure that clamps are in good working order, and consequently assist with developing better quality plastic products.

Injectdion mold clamps play a very important role in the daily work of the production plant, and they way it is used there has to be no different from any other piece of equipment or tool. The rest of the plastic production can be held up if these clamps are not functioning properly This will make the customers wait longer for their products, which does no good to sales and it might affect negatively on the company’s image. Products being wrong in its manufacturing due to the clamps will cost a ton of money, if any. Let your clamps being well-maintained and working properly is the first step to create plastic faster in China. This not only gives the factory a better quality product in warehouse, but you can get some more money on your production.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They injection mold clamps. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Our customers service focuses your satisfaction. We've been providing machining services and injection mold clamps with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Based on injection mold clamps and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Pingcheng is dedicated to helping customers injection mold clamps by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.