Injection molding machines are invaluable in production. They produce a wide range of goods by shaping plastic and other materials through a variety of means. Pingcheng’s horizontal Assembly injection machines are the most popular because they are easy to use and much more efficient. They don’t take up much space, and they lay flat (so it’s easy to add raw ingredients to them or pull out the finished product). This article takes a closer look at how flexible horizontal injection molding Large castings machines from Pingcheng can meet various production requirements, including productivity improvement, product quality precision and profit-boosting as well.

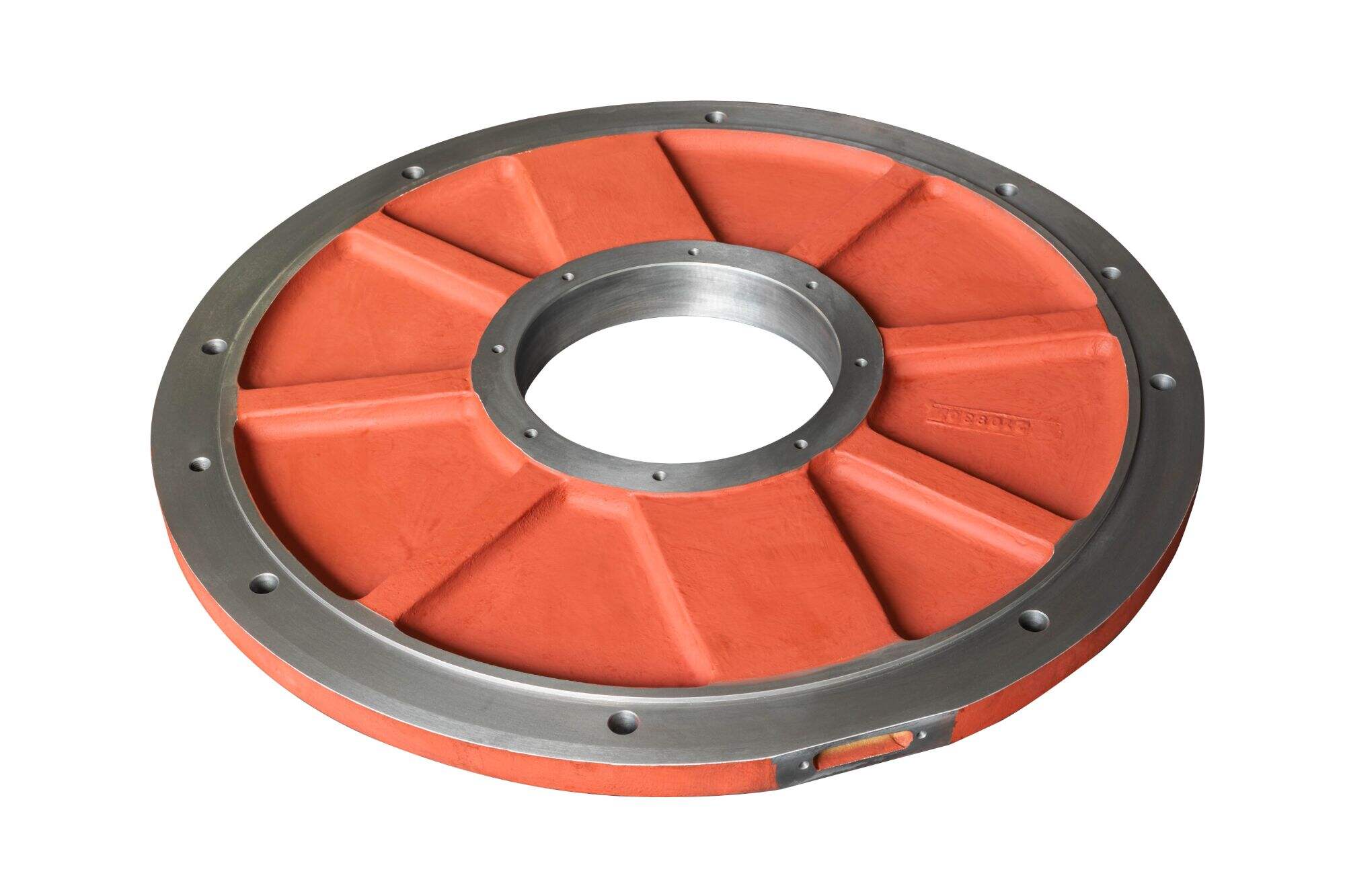

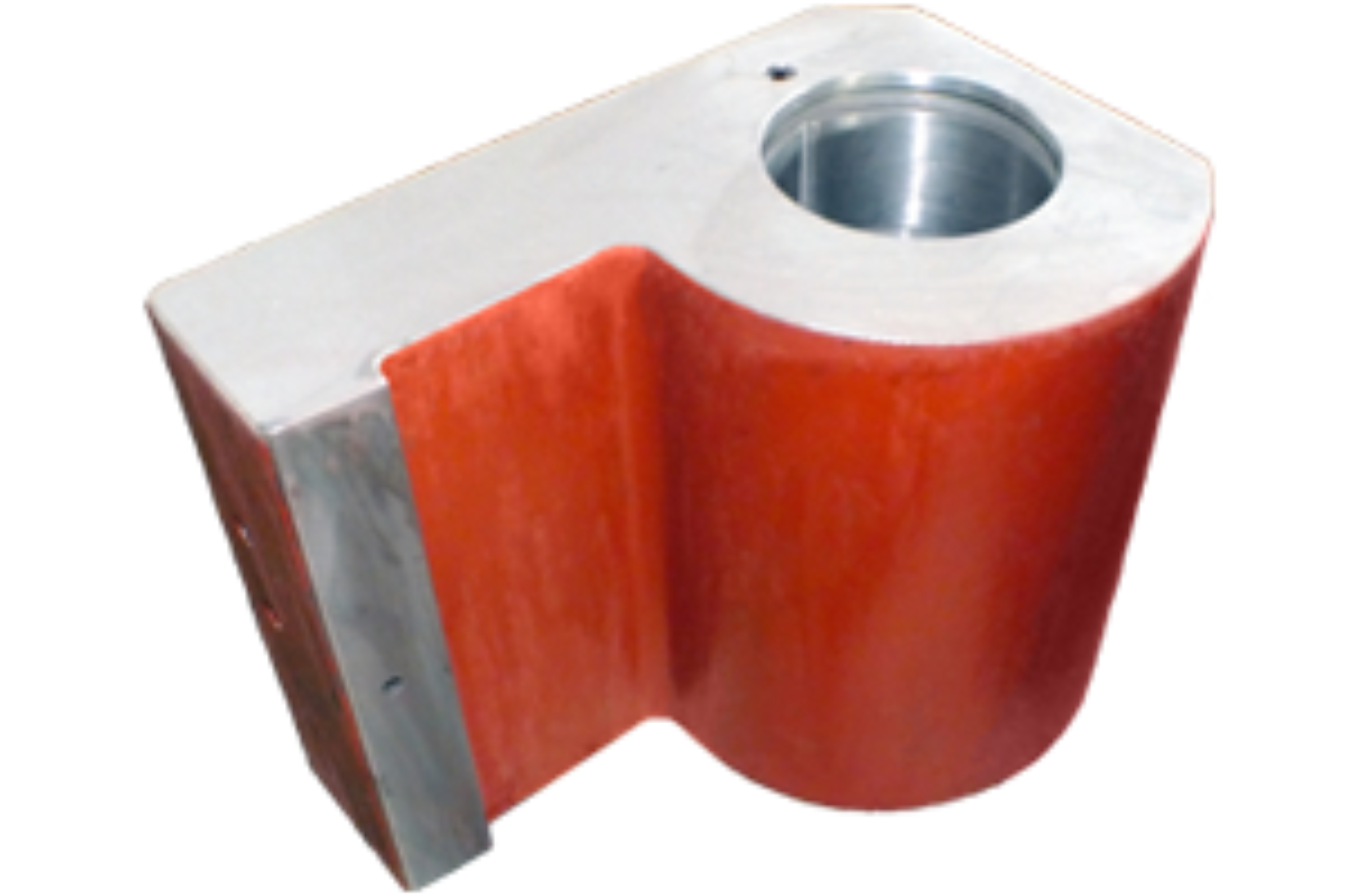

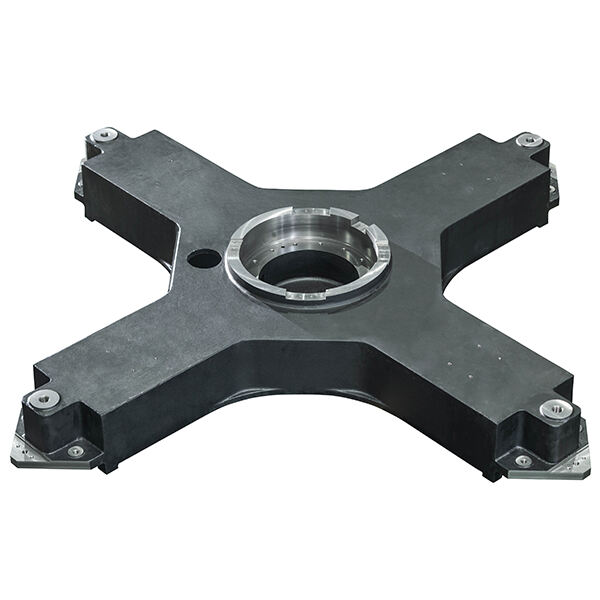

Wholesale good quality injection molding machine Injection Molding Machine - Centre clamping structure - Cast aluminum characterristic - Individual hyaulic system - ATOS systerm and GEFRAN system * - Competitive price, professional excellence and high stability.

Pingcheng provides with best quality and best price of horizontal injection moulding machines to our wholesale customers. These are durable machines that are made with materials of superior quality and are equipped with the most cutting-edge technology. They’re fast workers: In no time at all, they can produce a large number of items. This enables buyers to rapidly balance their orders and not be concerned about machines breaking down. And Pingcheng machines require less power, which cuts the cost of electricity bills for buyers.

For those businesses that want to produce more products in less time, Pingcheng also have horizontal injection molding machines solution. Their design allows workers to see and reach the mold easily, to add materials and take out products more quickly. That arrangement enables factories to produce more items a day and to meet their production targets more quickly. Plus, the less time you spend maintaining something, the more time you have to make products.

Picking the right setup is the ticket to savings and efficiency in manufacturing. Pingcheng’s horizontal injection molding machines are constructed to be more energy efficient, which cuts costs. They also don’t need as many repairs due to their basic, solid construction. This will save you money on maintenance and ensure the machines run smoothly for years, so they are a wise investment for any business.

One of the great points about Pingcheng’s horizontal injection machines is that they can create very accurate and precise products. A small toy, part for a car, or whatever, comes out looking exactly like it should. This level of accuracy assists business to make sure that their products adhere to stringent quality standards and please their customers.

Pingcheng is a full-service and injection molding machine horizontal. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Pingcheng is dedicated to helping customers injection molding machine horizontal by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate injection molding machine horizontal as soon as we can, and provide the best solution for your cost.

Pingcheng has now more than 20 manufacturing machines and injection molding machine horizontal with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.