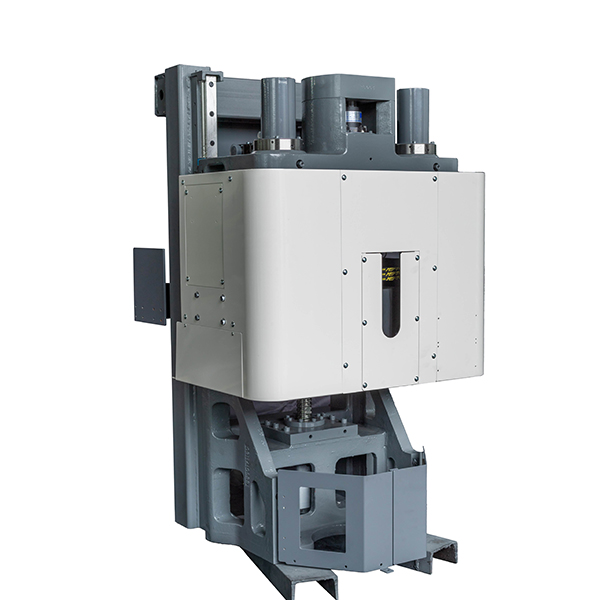

What is a Rotary Vertical Injection Moulding Machine? Pingcheng vertical injection molding machine with rotary table is a very particular kind of machine that does its work with plastic products in the way filled firmed mode. This is an advance technological machinery that forces hot molten plastic into a mold. The plastic cools and holds the shape of the mold. It is also very precise technology so it does a great job of producing parts that can be either large or small depending on what the part may require.

Many kinds of products can be produced by the rotary vertical injection moulding machine. It might sound like the 3D printer can only make parts for really cool cars or toys, but in fact it could be used to produce types of medical devices and even everyday items such as your measuring spoons and mixing bowls. It is a very flexible machine that allows it to easily adjust values and produce different sized and shape parts. Pingcheng vertical injection molding machine can hence manufacture a diverse range of products of different types by the same machine. In factories where various sorts of products are produced, this can be very useful.

This machine is fast, which Tbh might be the best thing about it. When thousands of a single item need to be made, that matters because it can produce many products in the blink of an eye, and is incredibly important. The machine is fast enough to inject the melted plastic into the mold, and then cool it just as quickly. This vertical injection machine implies that it can manufacture many parts in very short time. Have you ever dreamed of an automated machine that manufactures the toy part thousands a day in a factory?

Further, good manufacturing process is really important to build out products and for that with properly made. The rotary vertical injection moulding machine is high accuracy. This Pingcheng vertical plastic injection machine allows it to make identical or nearly-identical parts. It is of utmost important for the products that demands accuracy. An example is the need for medical companies to be sure that their products are made properly, as they must work well and not put users in harm. If parts are not manufactured exactly, we could be in serious problems.

This machine, however was designed to be great for saving space. That means it is a similar machine to other machines that do the same job, but takes up less space. More machines in less space because the more area one machine takes, lesser other can fill. Pingcheng vertical injection molding machine price is of great help in factories, where the space available to cross objects are limited. More machines means more production in less time, hence factory becomes efficient and productive.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and Rotary vertical injection moulding machine. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate Rotary vertical injection moulding machine as soon as we can, and provide the best solution for your cost.

Pingcheng has at Rotary vertical injection moulding machine and 50 technical employees who have experiences. They are committed providing tops quality. Mitsutoyo's measuring instruments and CMM are calibrated regularly. The double-checking keeps quality reliable and accurate. Each keys part traceable and controlled during machining and assembly.

Our customer service focuses on your satisfactions. We have been offering an Rotary vertical injection moulding machine and developing a strong cooperation with industry well-known Japanese enterprises for over 20 years. Based on decades experience and comprehensions of this industry, Pingcheng is dedicated to offering our customers honest prices. We review the drawing using specialized software and provide most effective solutions at the most reasonable cost the moment we receives an inquiry for a quotes.