Molding machines accumulators have for one done a great deal in transforming the making of things within factories and workshops. These Pincheng machines create a large amount of heat and pressure to form materials into various shapes and sizes which help the people to produce their products in a well structured way. Once upon a time, people produced everything by hand and one at a time. It was really hard to accomplish even simple things in this process. As of yesterday, however this molding machine changed all that. Companies were able to produce far more products in a smaller amount of time with the use of these molding machines. This sped up the rate of production which in turn brought prices down, making it cheaper for everyone.

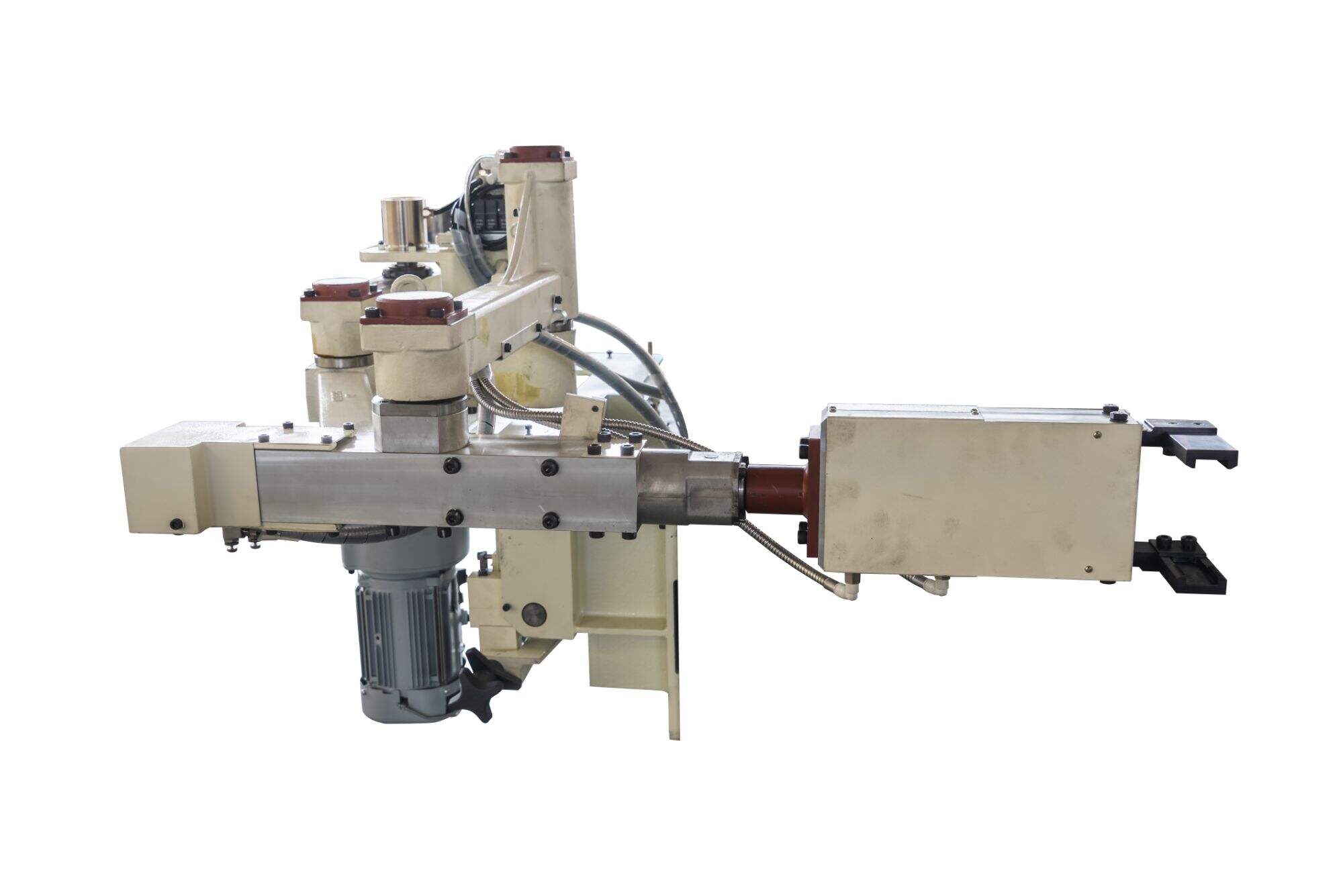

A Molding machine and high pressure accumulator is the equipment that pushes liquid or plastic material into a hollow shape known as the mold. Once the material is placed into the mould, heat and pressure are applied to generate a shape identical to that of the design. Injection molding process the molding machine consists of four essential parts placed outside the mold, a storing area for material which is prepared to load with an injected unit, and at least later one together form cranial or recovery station clamp. Most of this machinery carried out manually but other can process automatically with the presence without much human labor. They come in all sizes and shapes, being able to fabricate anything from tiny devices like toys or massive objects.

Injection molding hydraulic accumulators is a multi-step process, each of which takes place in sequence some after the other. The material that will be shaped is first placed in the hopper at the top of machine. This material is then melted by the machine in an injection unit. The melted material is injected into the mold itself at very high pressure, after it has been molten. This is for the proper distribution of liquid to all parts of the mold. Once inside, it has to cool down enough that it will harden and hold its shape. After cooling down the mould is opened, and a new item is extracted. In a single day, this whole process can repeat itself thousands of times which enables businesses to produce goods in large quantities and that too at very fast speed.

Proper selection of the press machine pressure accumulators is indispensably critical to producing high quality products in a bigger amount quicker. Every molding machine has different features and operations, so it is very important that you select the suitable one for your needs. You will need to decide what kind of products you wish to make, how many and how much money your budget. You also need to keep the machine maintained and make sure it works well at all times. This is fine for keeping the system running at peak performance and producing higher-quality product.

Pincheng aim is to assist manufacturing companies produce items of correct shape and quality, an important pre-requisite for business. Since then, molding machines and heat accumulators could quickly produce prototypes on a large scale where the designers tested new ideas and back tracked if any changes were to be made. This rapid ability to construct and re-configure designs helps save time, saves money and it will lead you towards producing better products that people actually want.

Pingcheng today has more than 20 manufacturing facilities and more than Molding machine. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a Molding machine you've been searching for. We are a partner which delivers opportunities.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We Molding machine, recreate it in specialized software, and then provide the most competitive price.

Pingcheng is a Molding machine and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.