قد يكون بعضنا فضوليًا حول كيفية حركة تلك طواحين الهواء لأننا نراها تدور في الهواء. هل سبق وأن تساءلت عن كيفية عملها؟ انتظر حتى تكتشف ما بداخل هذه الطاحونة، نعم هذا الشيء يُسمى صندوق التروس. هذا الصندوق هو مكون أساسي يسمح للطاحونة بإنتاج الكهرباء لمدارسنا ومنازلنا.

التوربين الهوائي هو آلة تقوم باستغلال طاقة الرياح وتحويلها إلى طاقة كهربائية. يحدث حركة الدوران للشفرات عندما يمر الهواء بجانبها، مما يؤدي إلى قوة كبيرة تجعلها تدور وتدفع التوربينات الهوائية. إن هذا الحركة الدورانية هي التي تولد الطاقة. يجب أن يكون للتوربين الهوائي صندوق تروس، بدونه لن يعمل. فهو يساعد على جعل الشفرات تدور بشكل أسرع، مما يعني أنها يمكن أن تنتج المزيد من الكهرباء لنا.

صندوق التروس هو نوع من الآلات الخاصة التي تحسن الكفاءة والوظائف. صندوق التروس - وأجزاؤه المهمة الأخرى هي التروس التي تعمل داخل صندوق التروس. تُستخدم هذه التروس لتسريع الشفرات. يتم تحويل استجابة الدوران البطيئة للشفرات إلى دوران سريع داخل صندوق التروس الخاص بالتوربين. إن هذا الدوران السريع هو الذي يدير المولد ويولّد الكهرباء.

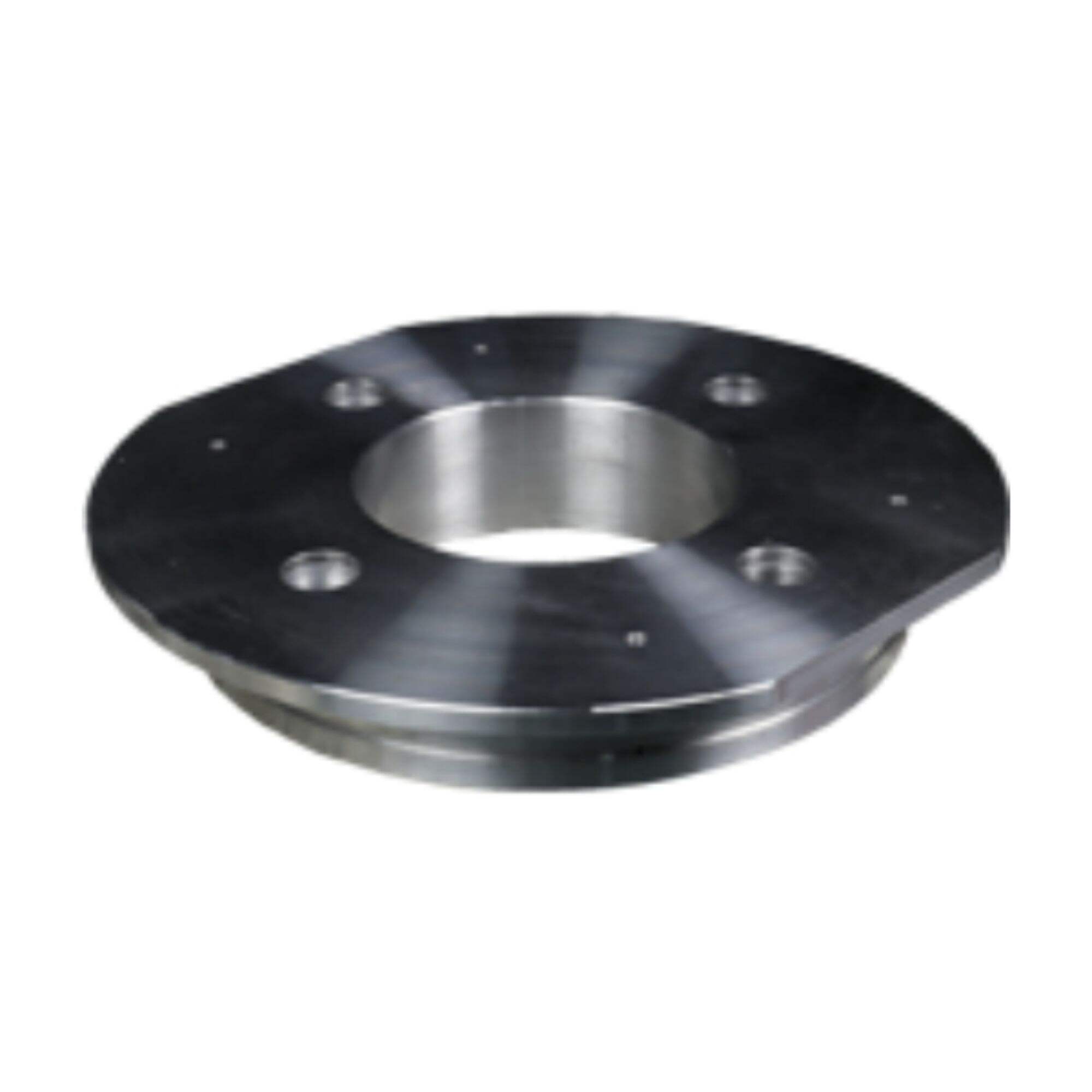

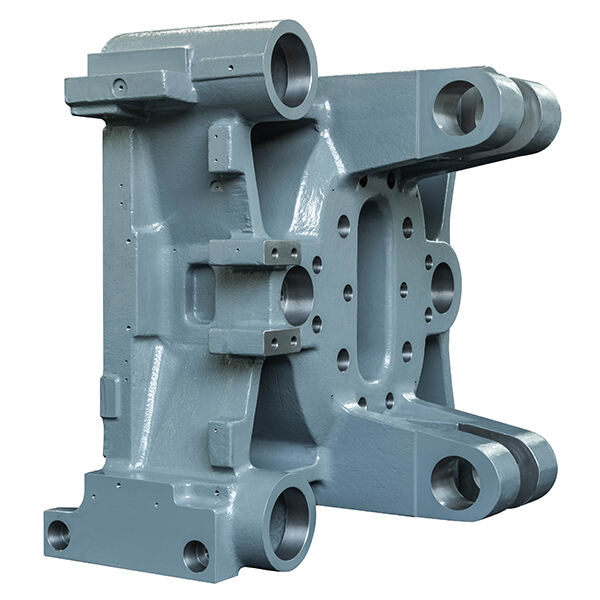

هذا مخروط الأنف موجود في توربين الرياح حيث ستجد صندوق التروس. هذه جزء من الطائرة تواجه اتجاه هبوب الرياح. صندوق التروس مصمم لحماية جميع التروس والأجزاء من الأحوال الجوية السيئة والظروف القاسية. يجب أن تعمل هذه التروس المختلفة داخل صندوق التروس بشكل متناغم لإنشاء شفرات تدور بسرعة أكبر. الأجزاء مثل الدعائم وخواتم الإغلاق تلعب أيضًا دورًا أساسيًا في ضمان تشغيل كل شيء بسلاسة دون أي تسريبات.

وقد تطور تصميم صندوق التروس في توربينات الرياح بشكل كبير أيضًا، كل ذلك بفضل التكنولوجيا الأكبر والأفضل. الصناديق الجديدة مصممة لتكون أكثر كفاءة، مما يعني أنها يمكن أن تعمل بشكل أفضل وتوفّر الطاقة أثناء القيام بذلك. كما أنها مصممة لتعمل لفترة أطول من النماذج القديمة. بعض توربينات الرياح الحديثة تستخدم نظامًا يُعرف باسم الدفع المباشر. بهذه الطريقة، يمكن الاستغناء عن صندوق التروس تمامًا! بدلاً من ذلك، يستخدم جهاز توليد أكبر ولكنه يحتوي على عدد أقل من الأجزاء المتحركة، مما يوفر صيانة أبسط وتكاليف صيانة أقل.

تم تصميم سلسلة التوريد والخدمات التي تقدمها شركة بينغتشنغ لمساعدة العملاء على تحقيق أهدافهم التجارية. ونركّز بشكل خاص على توسيع نطاق علب التروس المستخدمة في التوربينات الهوائية. وتُعد شركة بينغتشنغ المصنِّع الموثوق الذي تبحث عنه. فنحن شريكٌ يوفّر حلولاً متنوعة.

بينغتشنغ هو شريكٌ شاملٌ في جميع مراحل العملية ودورة الحياة. وتوريد المنتجات ليس سوى بداية شراكتنا. وخدماتنا للعملاء تهدف إلى ضمان رضاكم التام. ولقد كنا نقدِّم خدمات التشغيل الآلي ونبني شراكات وثيقة مع مصنِّعي علب التروس المستخدمة في توربينات الرياح لأكثر من 20 عامًا. واستنادًا إلى خبرتنا الممتدة لعقودٍ عديدة وفهم عميقٍ لهذا القطاع، تلتزم شركة بينغتشنغ بتقديم أسعارٍ صادقةٍ لعملائها. فعند استلام العروض، نقوم بفحص الرسومات باستخدام برامج حاسوبية متخصصة ونقدِّم أفضل الحلول بأقل التكاليف المعقولة.

وتضم شركة بينغتشنغ اليوم فريقًا متخصصًا في تصنيع علب التروس المستخدمة في توربينات الرياح، ويتكوَّن هذا الفريق من ٥٠ موظفًا فنيًّا يتمتَّعون بسنواتٍ عديدة من الخبرة. ويهدف هذا الفريق إلى تقديم جودةٍ عاليةٍ جدًّا. ثم يخضع المنتج للتفتيش باستخدام أجهزة قياس من شركة ميتسوتويو وأجهزة قياس ثلاثية الأبعاد (CMM) التي تُ calibrated بشكل دوري. أما عملية المراجعة المزدوجة فهي تضمن دقة وجودة المنتج واستقرارهما. كما يخضع تشغيل وتركيب جميع الأجزاء الحرجة للمراقبة الكاملة وإمكانية التتبع.

علبة تروس بينغتشنغ في توربينات الرياح تستند إلى عقود من الخبرة الصناعية وفهمٍ عميق. وبعد استلام طلبات الاقتباس، نقوم فورًا بفحص الرسومات ومحاكاتها باستخدام برامج متخصصة، ثم نقدّم الحلَّ الأمثل بسعر عادل.