Some of us might be curious about how those wind mills move around because we see them spinning in the breeze. Ever wondered how they work? Wait until you find out what is inside this wind mill, yes that thing is called gear box. This gear box is a crucial component that allows the wind mill to generate electricity for our homes and schools.

A Wind Turbine is basically a machine that taps the energy of wind and converts it into electrical power. The swirling motion of the blades is caused when air moves past, so that a significant force forces them to revolve and drive→ ←wind turbines. It is this spinning motion that generates power. Wind turbine must have the gear box without them it will not be work. It helps to get the blades spinning faster, meaning they can generate even more electricity for us.

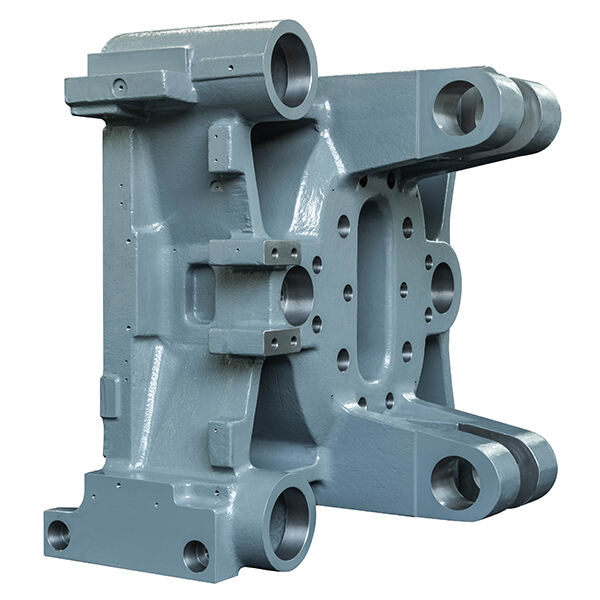

Gearbox is a kind of special machine which improves the efficiency and functions. Gear Box– its other important parts are gears which work inside the gear box. This gears are used for speeding up the blades. This slow-spinning response of the blades is converted to fast spinning itself inside the turbine gearbox. It is this rapid rotation which then turns the generator and produces electricity.

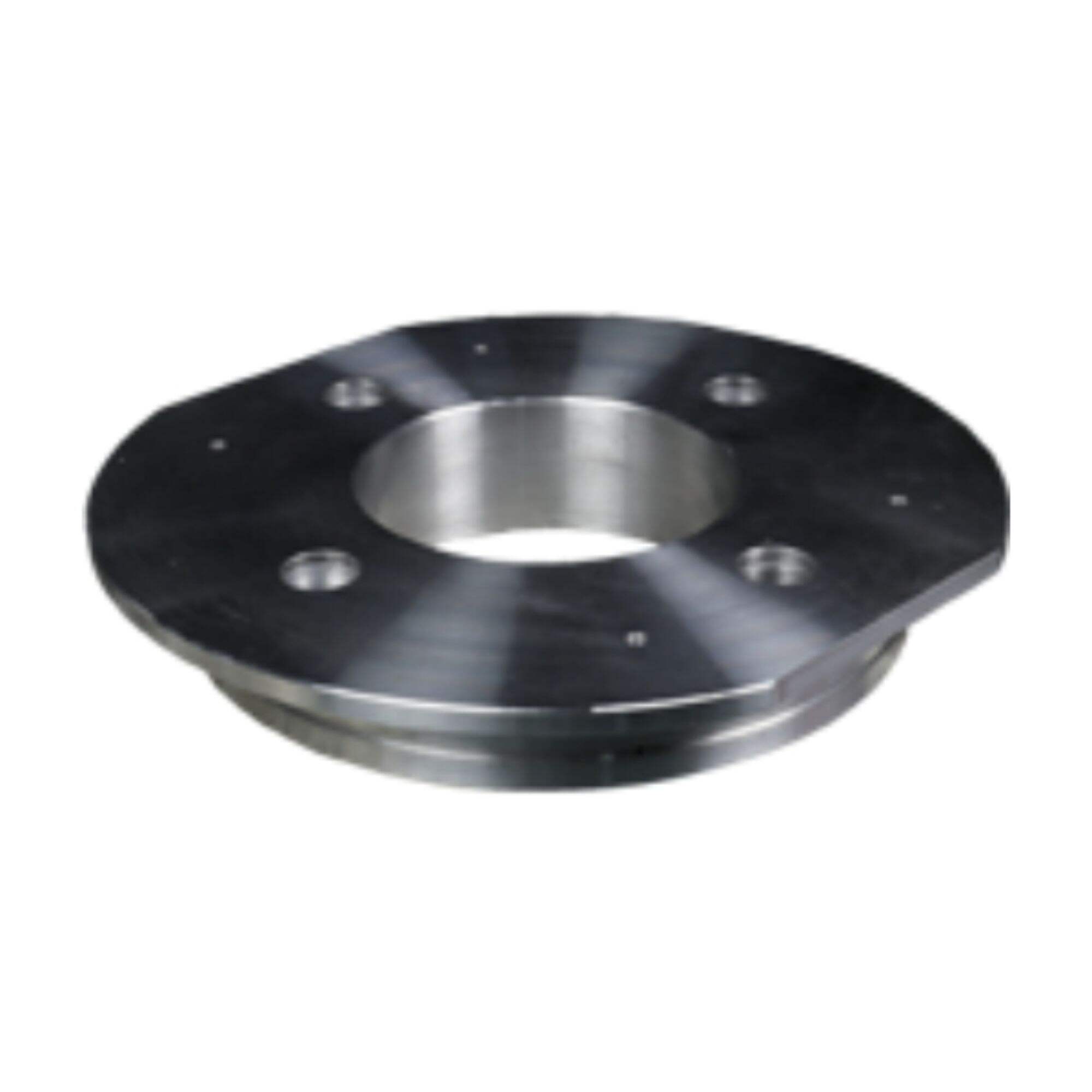

This nose cone is in the wind turbine where you will find a gear box. This part of the Kite faces the direction from which wind is blowing. The gear box is designed to safeguard all of its gears and parts from bad weather and hard conditions. These various gears inside the gear box must work in unison to create faster spinning blades. Parts like bearings and seals also play an essential role in ensuring that everything runs smoothly, without any leaks.

And the design of the gear box in wind turbines has evolved a lot as well, all thanks to greater and better technology The new gear boxes are designed to be more efficient, meaning they can perform better and save power while doing it. They are also designed to last longer than the older models. A few of the most recent wind turbines also use a system known as direct drive. Like this, they can do away with the gear box completely! Instead, it uses a larger generator but contains fewer moving parts that provides simpler maintenance and lower upkeep.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and gear box in wind mill. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with gear box in wind mill for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

Pingcheng now gear box in wind mill and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

Pingcheng's gear box in wind mill is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.