Pingcheng is a role model in clamp mould industry of industrial manufacturing. The molds are very important for the production of a number of products. Here you will learn how clamped molds benefit the manufacturing process, common problems with materials used to construct these tools and some troubleshooting options for clamp molds.

There are several benefits of using clamp molds in productions. One main advantage is that an accurate and homogeneous product can be produced. Contraction molds guarantee that every single product of any given type will be the same size, shape, and quality as the rest. Clamp Molding A clamp mold can facilitate flow lines and a mass production operation of the molding process. This improved efficiency can translate to cost savings and higher productivity rates for industries that manufacture goods. What’s more, the clamp molds are flexible enough to be adapted for different product types, which makes them a multi-use solution fitted for multiple industries.

Despite these advantages, clamp molds may encounter operational problems that can have an adverse effect on the manufacturing process. One common problem is mould sticking or adhesion in which the product adheres to the mould cavity and makes it hard (or impossible) for ejecting. To solve this problem, mold release agents can be used by manufacturers or equilibrium mold temperature can be changed to avoid sticking. Another common problem is mold flash, where injected material escapes through the mold seams as uncontrolled or excess material around the part edges. This may be resolved by regulating the clamp pressure or designing a more effective mold to minimise flashing. Mold erosion can also become an issue if the molds are not well maintained. The preservation of the molds can clean a mould itself and keep its surface smooth. By dealing with these typical usage problems and ma, the difficulties manufacturers can effectively troubleshoot further nufacturers kiye.su re smooth clamp molds working conditions of their Giving a wide variety in cal manufacturing operations.

There are many important questions to think about if you find yourself weighing the investment in clamp molds for your business. First things first, what do your products look like that you will be making with the clamp molds? Different molds are made to create different products, so its essential you select the right one for your specific needs.

And also you have to study suppliers around and check the prices, quality and reputation. You should be able to trust a supplier before you attempt to make the purchase of such items from them because this will guarantee that you are getting high quality clamp mold and that it would equally satisfy your needs for a long time. Thinking through these questions in advance of your clamp mold purchase will help you better understand how best a clamp mold will help your business.

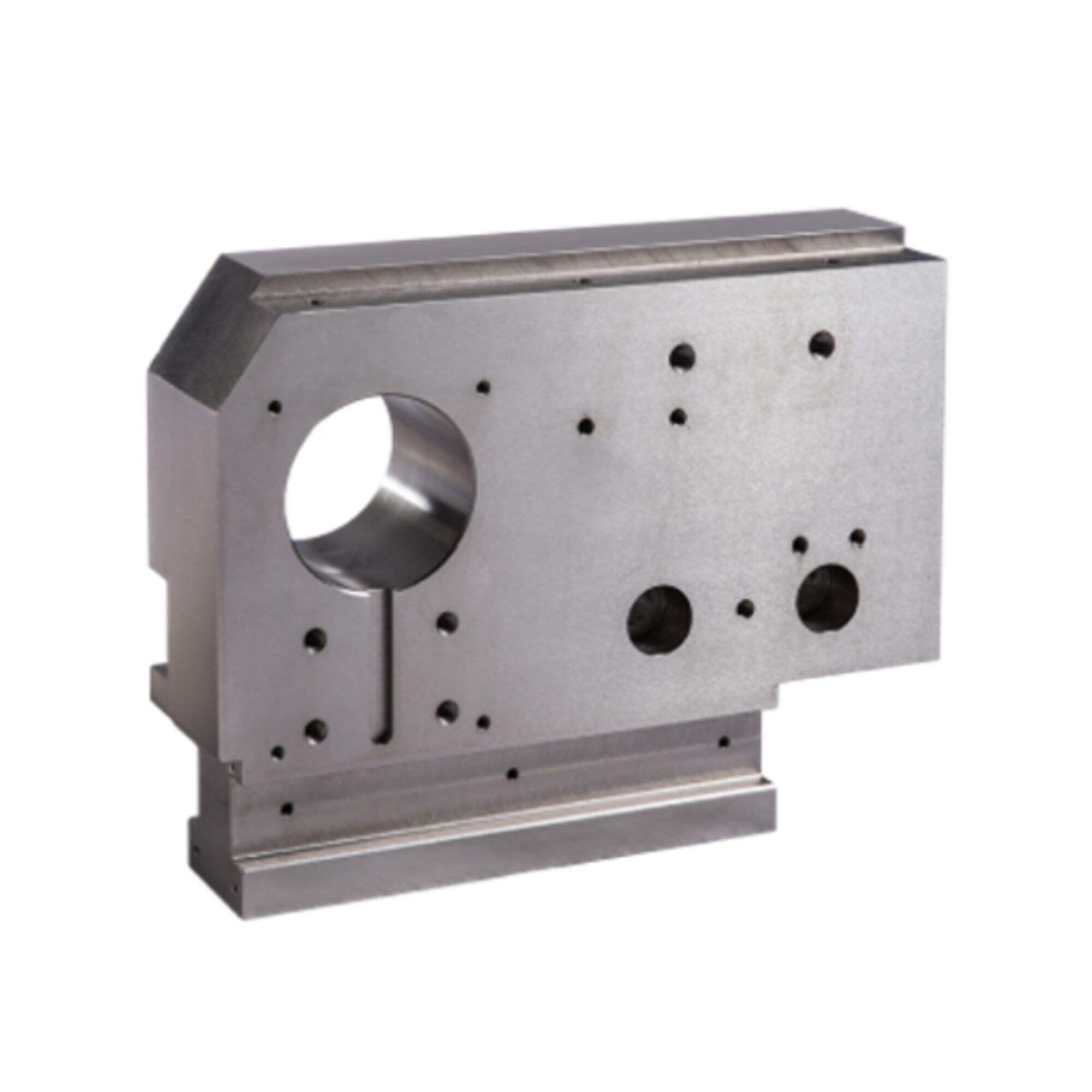

The material a clamp mold is made from is another key factor to think about when deciding on the clamp mold. Materials have a variety of properties which may influence the quality and efficiency of the molding process. You must also take into account the mold design and its features, including how many cavities there are and what type of cooling system is involved.

By choosing the perfect form of clamp mold for your work, you can be confident that you are doing as much as you can to get a great result. While you might have to pay more upfront for a quality mold, it pays off in the long run by streamlining your production process and helping you become more efficient sanitarily.

Pingcheng is committed to helping customers achieves their business goals through our clamp mold and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng now clamp mold and 50 highly skilled technical employees. They strives to provides high quality. Then, the products is inspected by Mitsutoyo measuring instruments and CMM that periodically calibrated. The double-checking keeps quality reliable and accurate. The machining and assembly of important parts controlled and traceable.

Pingcheng is a clamp mold and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we clamp mold, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.