Vertically, multiplas injection moulding machines hold a special place in industrial sectors to make an optimum use of our resource. These machines are faster, can give accurate parts in a few minutes or hours rather than days and weeks with significant time- cost-saving.

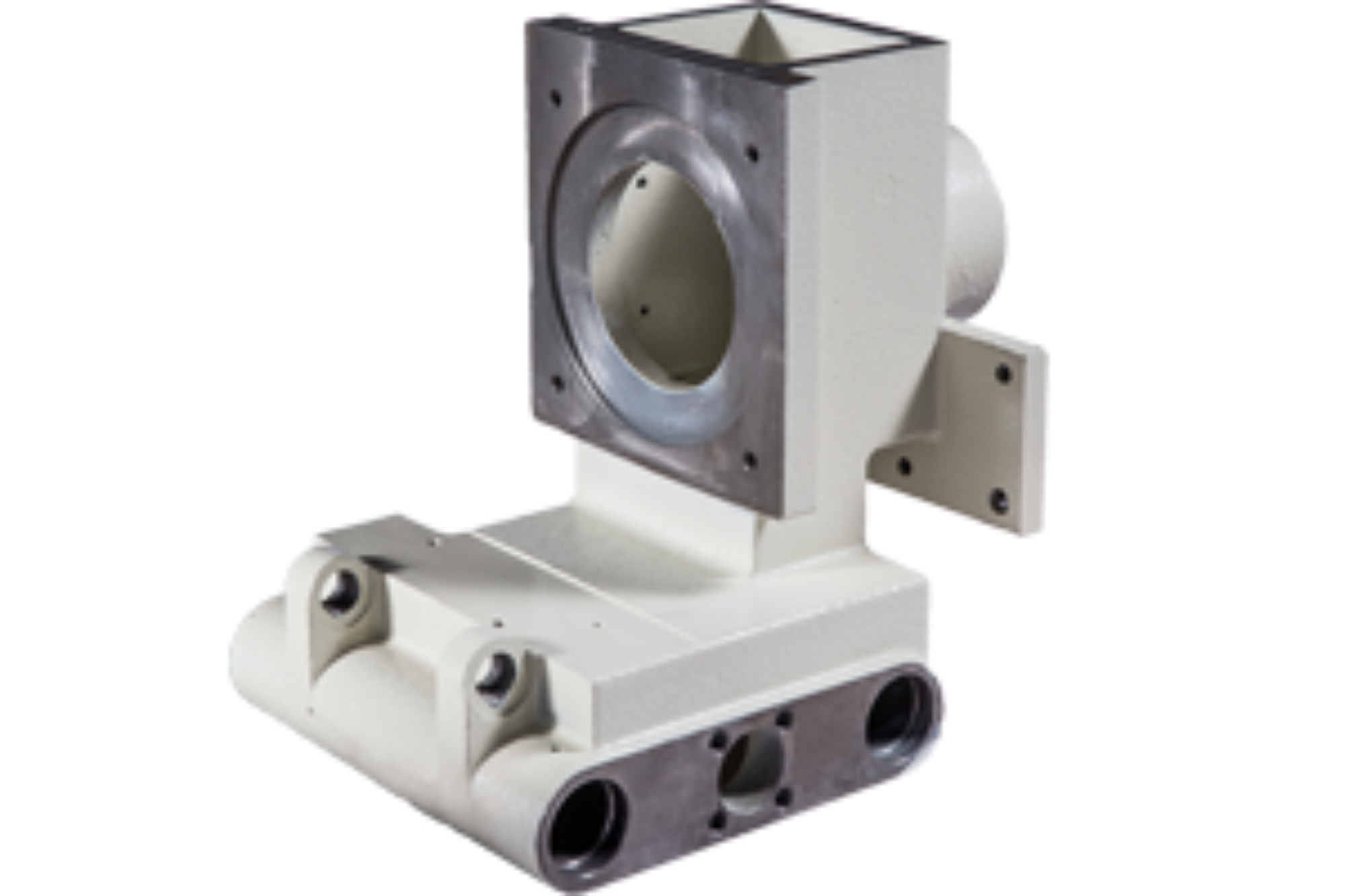

The first highlight of the Multiplas vertical injection moulding machines is versatility. By using these machines you can manufacture any product like from simple to complex designs with different materials such as rubber, plastic and metal etc. Due to their adaptability, they are used across a wide range of industries such as automotive, medical and electronics.

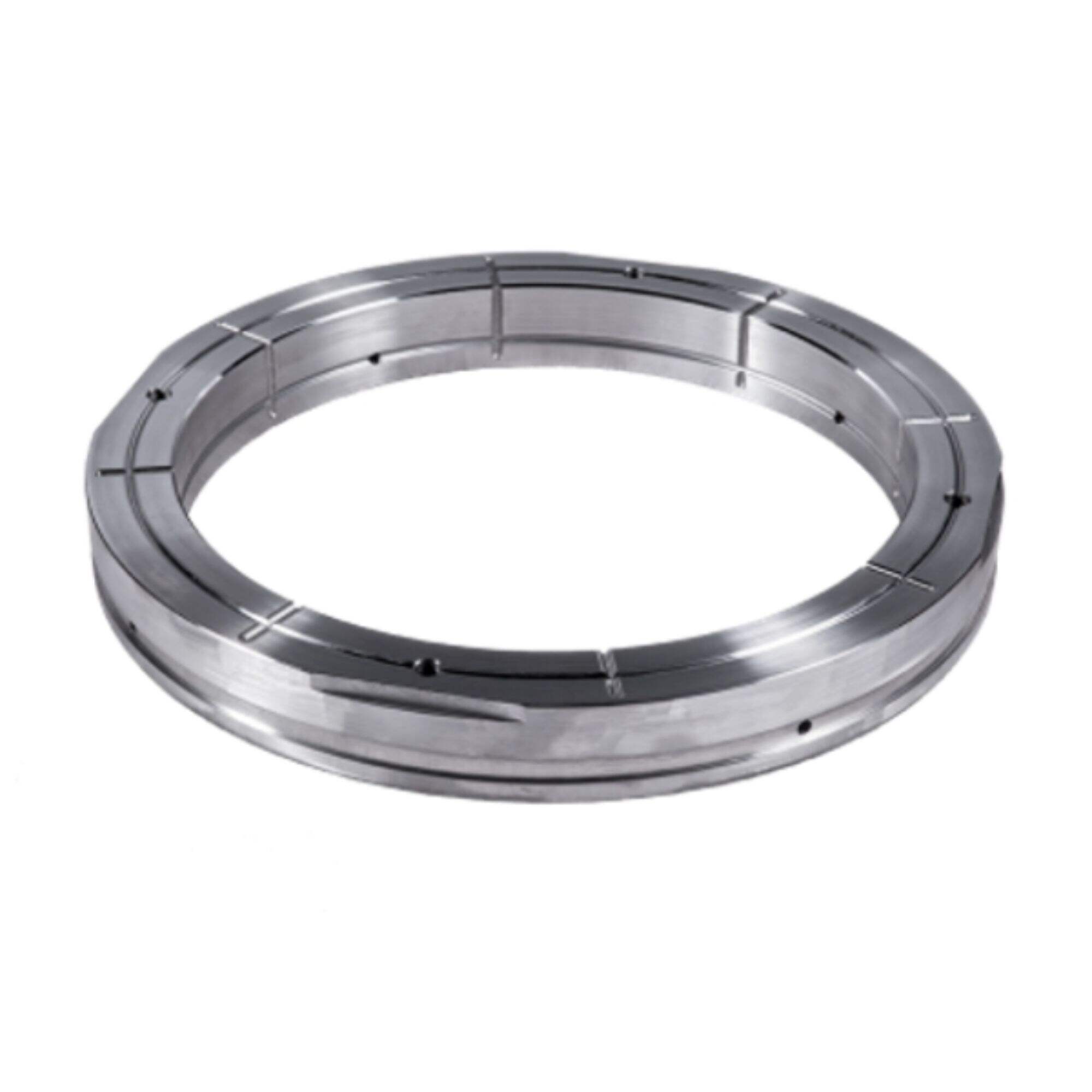

Quality Parts and Precision are the signature of Multiplas Vertical Injection Moulding Machines. These machines come with the latest technologies like touch screen interfaces and computer controlled system to guarantee a universal high quality output for every item produced. The products made by Multiplas vertical injection molding machines are the best quality, good aesthetic and has high durability.

Multiplas Vertical Injection Molding Machine - Offers compact design, energy efficiency and low cost features making it a favorite of many. Their compact design makes them installable in a small space which does not take up too much room. Furthermore, they are also known for their energy-saving characteristic and equipped machines used, of course; it saves a lot on expenses which is very handy to any business enterprise.

Multiple vertical injection moulding machines simplify the process of industrial machine, helping businesses run more efficiently. Injection moulding automation, in which the machines are designed to do all of the work automatically so that very little human labour is needed during operation. Additionally, they have an automated production system that allows parts and products to be constantly produced without long down times which makes them great solutions for large manufacturing operations. This seamless production flow allows them to cut down on costs, while also significantly driving productivity up.

In summary, Multiplas vertical injection molding machines are reliable and high-performance sets that help in raising business productivity while guaranteeing accuracy as well quality output. These machines are the latest in advanced technology, they are significantly cheaper to run and easy to use which benefits both cost efficiency saving resources and is environmentally beneficial by simplifying manufacturing process. From different industries, what stands these machines to be very useful and flexible is its precision and consistency that each while offering a complete package to cater all the demands of manufacturing.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We multiplas vertical injection moulding machine as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.

Pingcheng is a multiplas vertical injection moulding machine and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng's multiplas vertical injection moulding machine is based on decades of industry experience and understanding. We review the drawing, model it using specialized software and then provide the most competitive price.

Pingcheng today has more than 20 manufacturing facilities and more than multiplas vertical injection moulding machine. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.