Vertical Injection Molding Machines: Precision Manufacturing Without Dooming Into Oblivion

In recent years, vertical injection molding machines have revolutionized the manufacturing industry by enhancing efficiency and precision. These machines offer a versatile approach to injection molding, making them ideal for a wide range of applications, including medical device production and custom manufacturing.

Top 5 Vertical Injection Molding Machines for Precision Manufacturing

Vertical injection molding machines are a popular choice for medical device production due to their precision and efficiency. These machines can create anything from small connectors to complex surgical instruments, meeting strict safety and hygiene standards in a cleanroom environment.

High-speed vertical injection molding machines are game-changers for manufacturers seeking improved efficiency and reduced production time. These machines offer fast injection and clamping processes, leading to higher component production rates and shorter cycles, enhancing productivity and reducing costs.

Vertical injection molding machines are not only precise and efficient but also customizable to meet unique application requirements. They can be adapted to specific manufacturing needs by adjusting injection pressure, volume, and other characteristics, making them ideal for companies with specialized manufacturing requirements.

When considering upgrading manufacturing equipment to include the precision applications of vertical injection molding machines, it is crucial to choose the right machine based on your needs. Factors to consider include the size and complexity of parts, production volume requirements, and the level of training and support needed to operate the new equipment effectively. Vertical injection molding machines offer accuracy, productivity, flexibility, and customization, making them a valuable asset for various manufacturing sectors.

Our customers service focuses your satisfaction. We've been providing machining services and vertical injection molding machine with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng's vertical injection molding machine and services are designed to helps customers meet their goals for business. We are focused on expanding and increasing the potential and lifespans of your productions. PingCheng is a dependable producers you are looking for. We are a suppliers that provides opportunities.

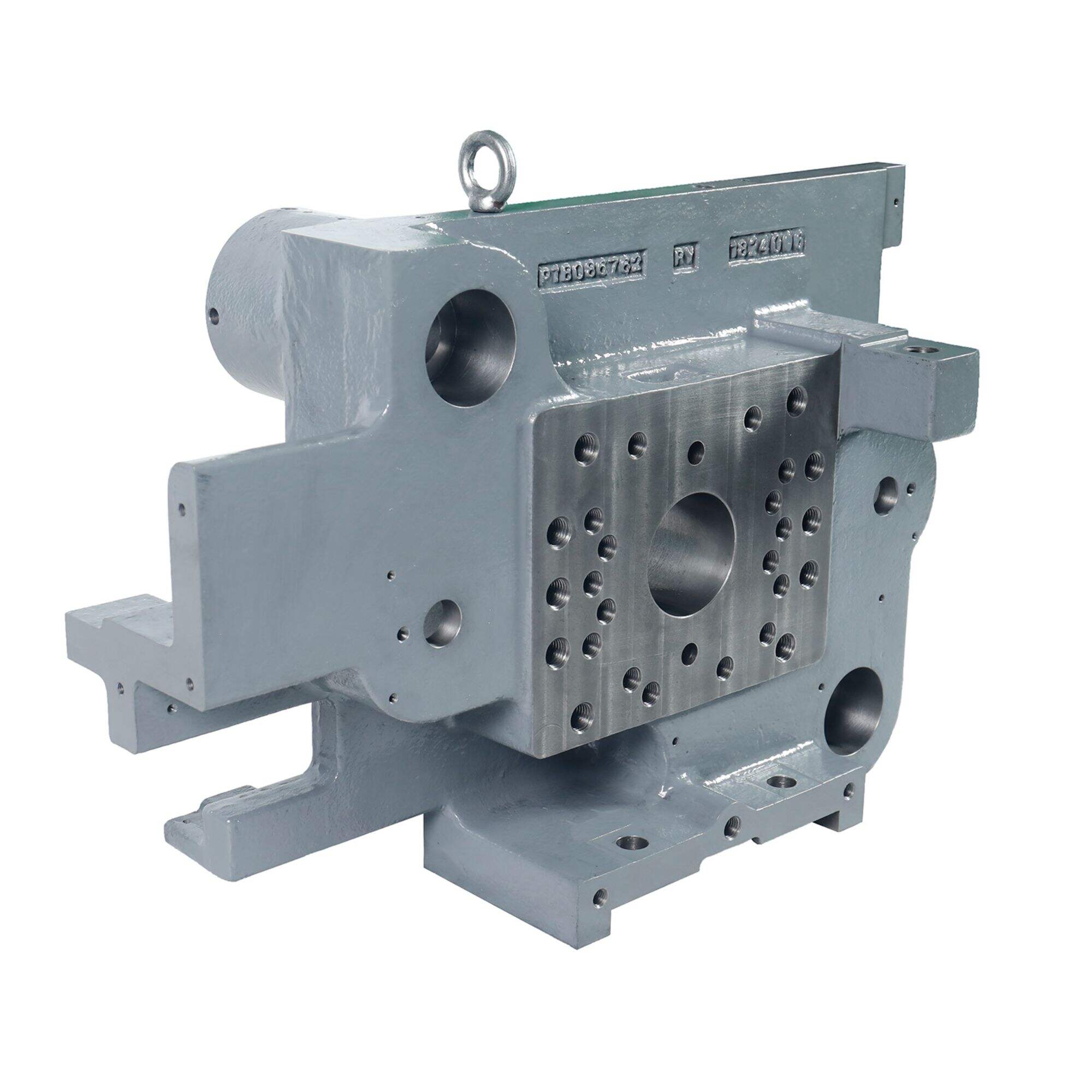

Pingcheng has now more than 20 manufacturing machines and vertical injection molding machine with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng's vertical injection molding machine is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.