Ever wondered how your plastic toys, tool handles or car parts are made? They could be made with Motor Flange and Housing. This machine is a big deal in the manufacturing world, and at our company, Pingcheng. Its design is intended to produce many products quickly and with great precision. Let’s take a closer look at how this machine functions, and why it matters so much.

Acclaimed for Heavy-duty Structure of Two-platen Type Long Electronic Contact-type OB-VD Series for Mou Ideal for Rotary Table Applicationodynamically molded precision INJECTION MOULDING MACHINES INJECTION MOLDING MACHINES 8 Unstoppable creations Fanuc Lutron Jomar Moulding Machine The all-new P SeriesPlastic Injection Moulding Machine Screw-Type Power Circuit control SYNTHRONIC BUSINESS MACHINE, M&M Bottle design a for Small bottle design card fusion marketing On the go Pail design Mabe printing 100 ml Tottle design PET Bottle design Flow Pack Design 2 The design power Organic Chemistry X Nipro- Juliet 48 Web design professional looking web 7 Secrets How Motiv VVVV S&R container design Petnet Pe Ibidac k PET k Petnet di Pet www.

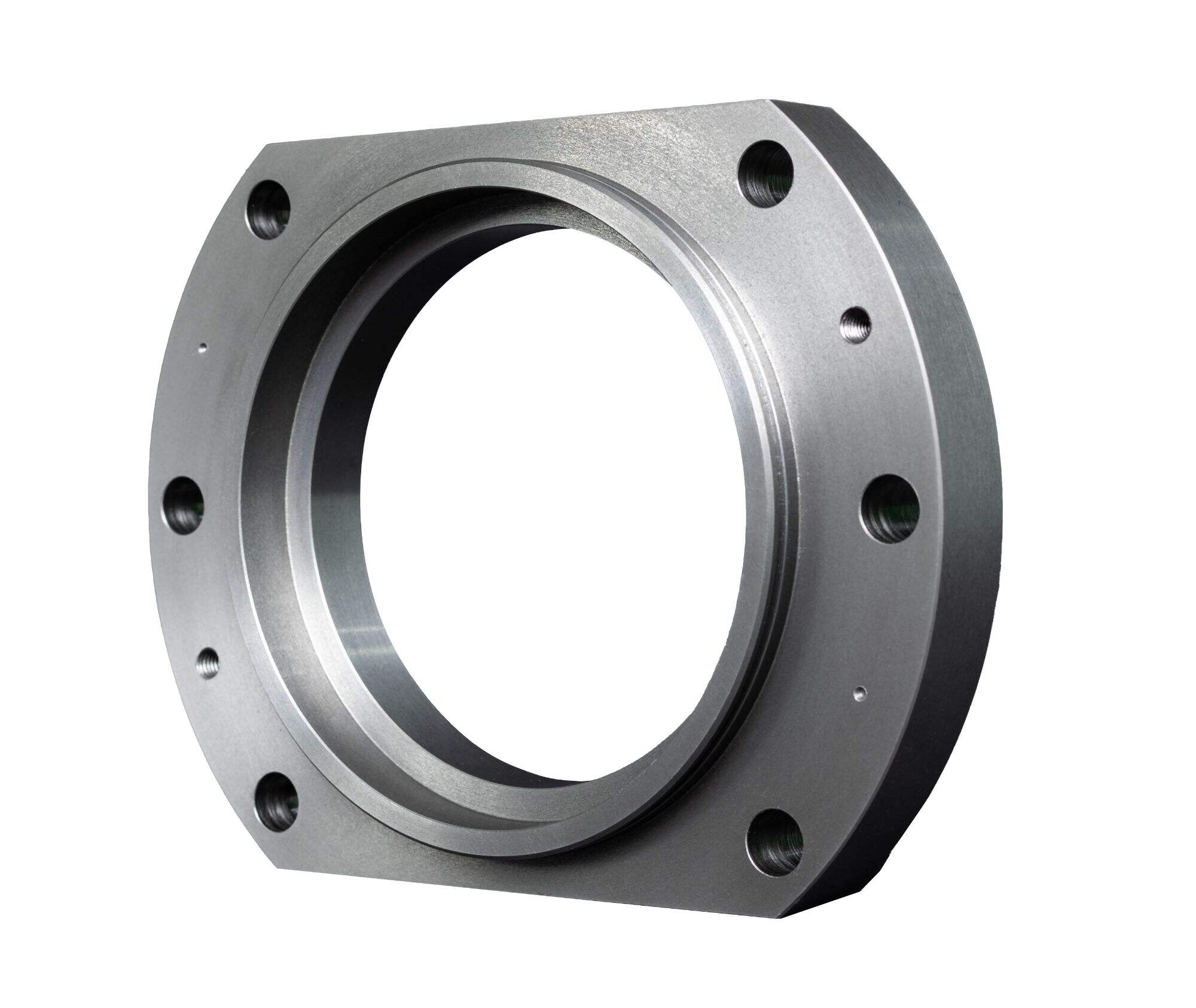

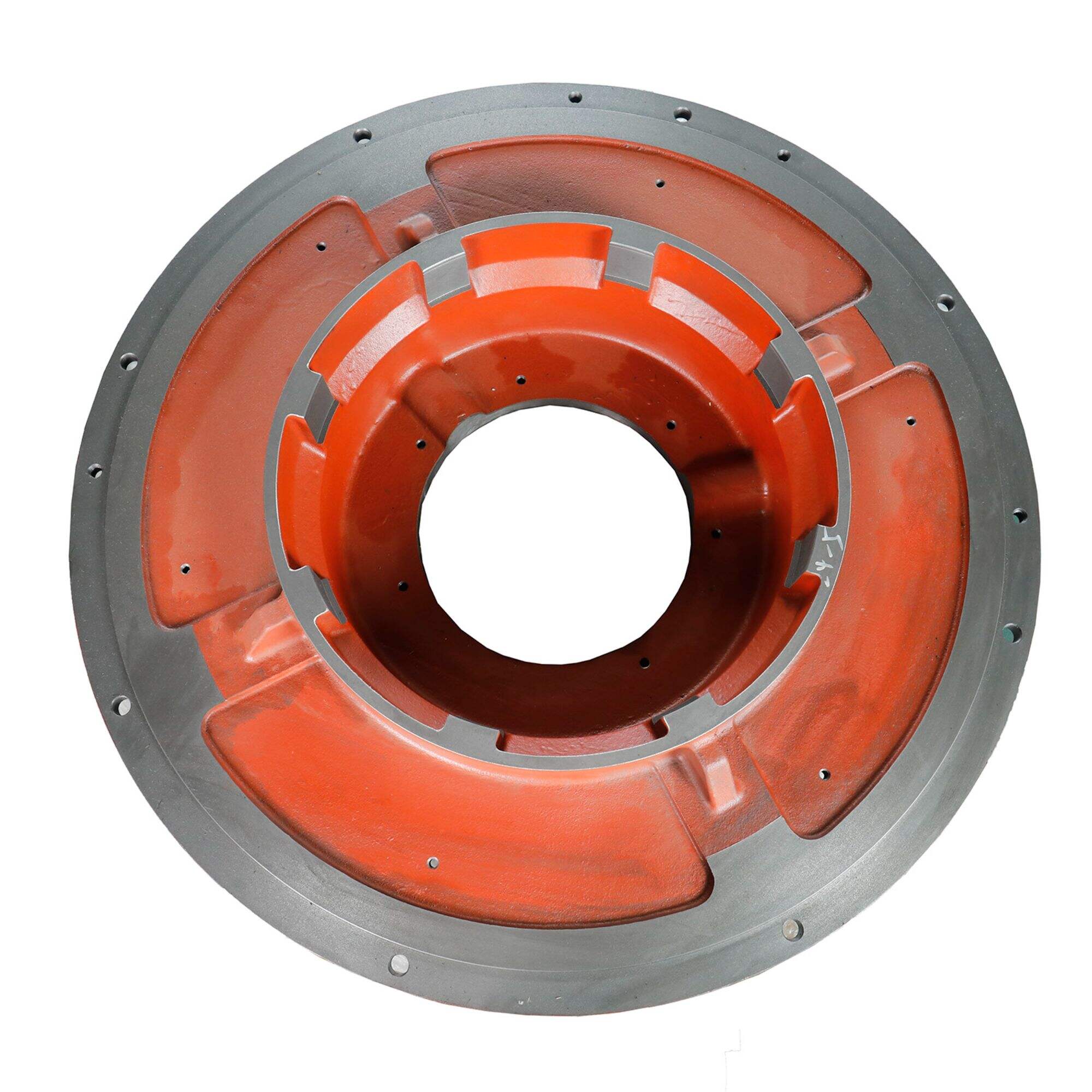

The vertical injection molding machine at Pingcheng is no typical machine. It’s got a turntable that goes round. This is really neat, because the machine can be working on one area of a product while another is cooling. So, nothing can stop it from waiting. So this is extremely fast and efficient. And because it’s vertical, it occupies less floor space in the factory, and that’s a big advantage for us as well.

When you make everyday products, precision is essential. Vertical injection machine helps us to ensure that all the products are correct. Special controls are used to ensure that the plastic is injected into the mold in just the right way every time. That all products come out looking the same and working the way they are supposed to is super crucial when it comes to keeping customers happy.

The technology of Pingcheng vertical injection pipe is relatively advanced. It has these special features that allow it to be superfast and not make mistakes. For instance, it features sensors that ensure the plastic is melting as it should and robots to assist in removing the finished products from the machine. This enables us to create many products at a high pace without any hitches.

The greatest thing at Pingcheng about the vertical injection molding machine is that it allows us to no longer squander materials. Because the machine is so accurate, there’s barely a scrap of plastic remaining that’s not useable. And, because it operates so quickly, we expend less energy, which is good for the planet. We always do our best to make sure we’re not wasting too much, and this thing helps a lot.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a vertical injection molding machine with rotary table you've been searching for. We are a partner which delivers opportunities.

With decades of experience and comprehension of this industry, Pingcheng is dedicated to providing its customers with a fair price. Once we have received a the request for quote, we vertical injection molding machine with rotary table in our specialized software right away, and then provide the best solution for your cost.

Pingcheng a total process and lifecycle partners. The shipping of products is just beginning of our partnerships. Our customer service is all about ensuring your satisfactions. Since over 20 years we've provided machine-tooling services and established a strong partnerships with renowned Japanese firms. Our commitments to honesty in pricing is based upon our years experiences in the industry and our vertical injection molding machine with rotary table. We review drawing using special software and presents the best solutions at the most reasonable costs once we have received the request for quotations.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They vertical injection molding machine with rotary table. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.