Vertical injection molding is a method used to produce products by injecting material into a mold. This process is unusual because the material is injected vertically, not horizontally. The result is a more accurate and intricate component. We, as Pingcheng, apply this way in our production of good products for our customers. Find out why vertical molding makes the perfect solution for wholesale buyers, how it can improve the quality of your products while saving you time and money: Providing Quality - Consistency by Design There are plenty of demands on your manufacturing business, not the least of many is the demand for a product that provides consistent quality and economy.

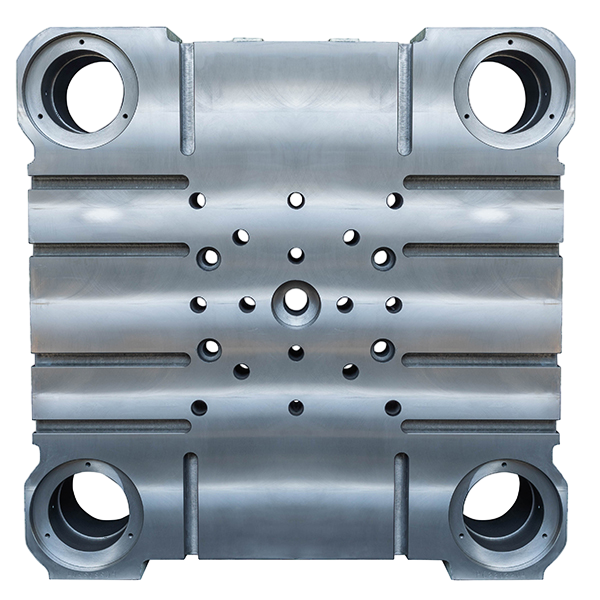

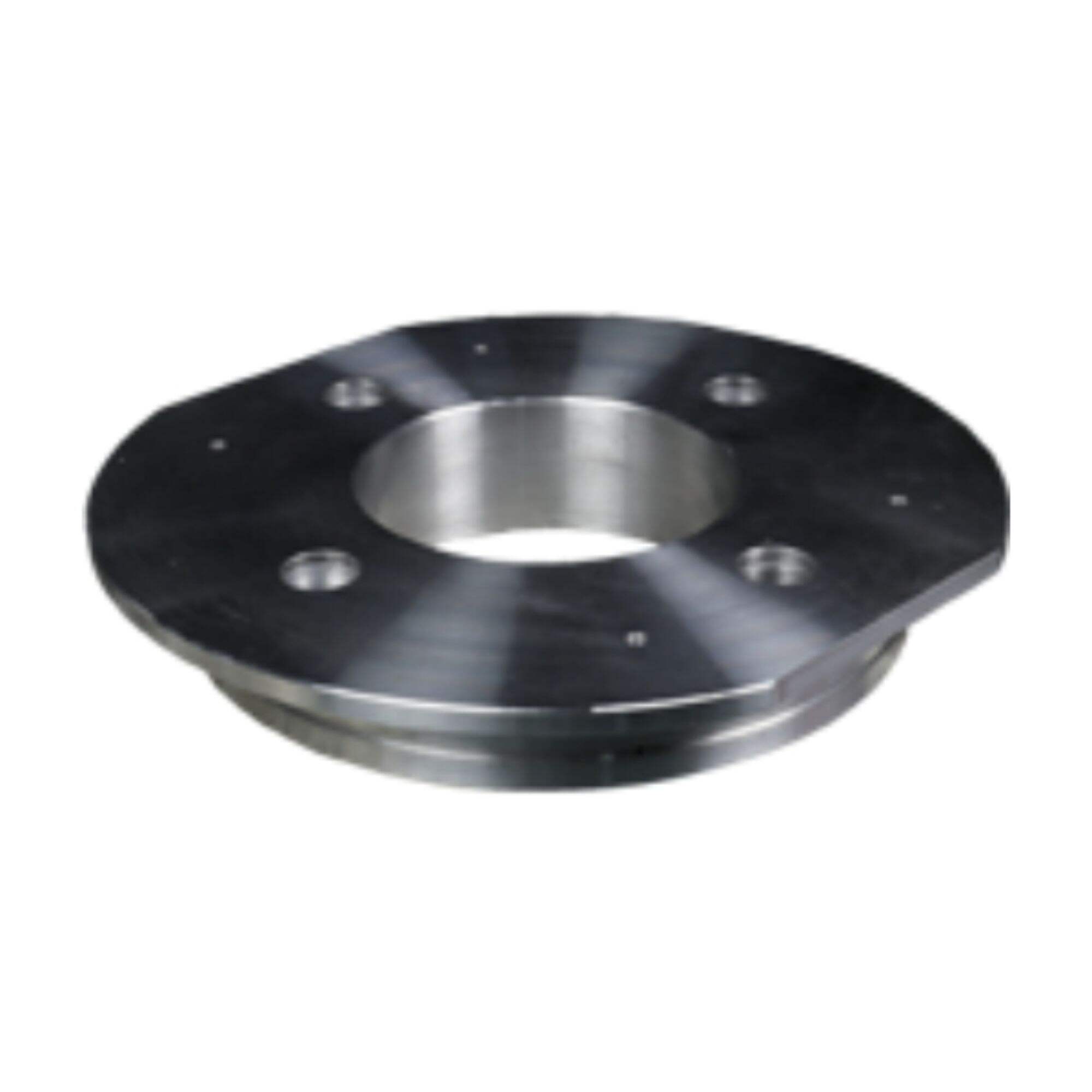

Wholesale customers will always be looking for the best products at the best prices. They prefer the use of vertical injection moulding machines as it is capable of producing intricate moulds with greater accuracy. Because filling of the mold goes on under the vertical direction, there are no double stabilizers in the molded article, and a low defectives molded article can be made, so as to be able produce high-quality one. And, Pingcheng is able to churn out high volumes at a rapid pace, so wholesale customers can receive products quickly and begin selling them to their own customers rapidly.

Available in vertical inject and horizontal inject (above the clamping unit). Quality of the products produced is usually poor when compared to Product products manufactured with the vertical injection. This is because the gravity of the situation aids in filling the mold more evenly and lessens the risk of trapping air, which can cause defects. Considerable amount of work that we put into our products in Pingcheng We employ state of the art machines and premium raw materials to ensure every product is up to our standard. This means our customers can trust that they are receiving the best products for their money.

The use of vertical injection molding can also be more cost effective and it can improve productivity. For instance, the molds for vertical injection molding can, in many cases, be easier and less expensive to form. This is good as it saves some money from the beginning. It’s also the process that can be automated, reducing labor costs and expediting production. At Pingcheng, we've streamlined our vertical injection molding operations to deliver the highly efficient operations you need to be successful.

The speed with which vertical injection molding can be carried out, is one of the biggest benefits. This enables rapid mold changeovers and faster cycle times, which equals increased productivity within less time. For businesses needing to respond swiftly to market changes or on tight deadlines, the effect can be huge. Pingcheng is more about working tight production schedules, not long ones, and makes sure that we’re always able to meet our clients’ deadlines.

Pingcheng has now more than 20 manufacturing machines and vertical injection molding with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Pingcheng is vertical injection molding achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We vertical injection molding, recreate it in specialized software, and then provide the most competitive price.

Pingcheng is a full-service and vertical injection molding. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.