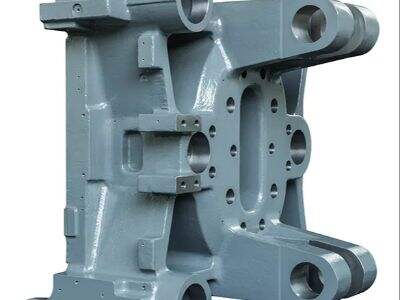

When it comes to products made of a single material, no form of manufacturing is more popular than injection molding. Did you even know that these machines have moving parts that wear out? Wear is what happens when parts rub up against each other frequently. This can cause the machine to not work well or even break. But don't worry! Wear in the moving parts in injection Molding machines can be minimized to help keep them running smoothly, and longer.

One of the effective methods to prevent wear in injection moulding machines is lubrication.

Lubrication is covering the parts that come into contact with oil or grease. This makes it easier for them to move. It can help prevent wear and tear on the machine’s moving parts by supplying the right amount of lubricant on a regular basis. Generally it’s a good idea to refer to the owner’s manual to learn how to lubricate the machine to ensure that it operates well.

The machine settings can be checked and adjusted, there by helping to minimise wear.

A machine sets the pace at which the parts slide and how much pressure is exerted to shove plastic into the mold. By inspecting these settings and altering them whenever necessary, you may be able to help stop the machine from wearing too much. It’s also useful to collaborate with a machine operator or technician to ensure your equipment is properly set up and running efficiently.

Selecting the proper materials for the moving parts is important as well.

Some materials are stronger and last longer than some others. And you can help them last longer and replace them less frequently by using good quality materials in the machine’s moving parts. It’s wise to consult with a materials expert when selecting parts for your njection Molding machine to ensure they can withstand daily usage.

Preventative maintenance and inspection are important to halt excessive wear on the moving parts. Just as you look after your toys or bikes to keep them neat, machines too need to be checked regularly to be in good condition. If you keep a schedule of maintenance and you’re able to identify signs of wear and damage, you can see problems early and fix them before they get much worse. Creating a maintenance checklist and sticking to a regular cleaning and inspection schedule isn’t a bad idea.

Cooling and heating techniques are also essential to help the moving parts last longer.

Cooling and heating regulate the temperature of the plastic within the machine. When the plastic is too hot or too cold, the product’s quality can be negatively affected, and more pressure can be placed on the machine. By employing the proper cooling and heating techniques, you can maintain the machine at optimal temperature, thus cutting down on wear and extending the life of its parts. You can also work with experienced technician to provide proper cooling and heating systems for your injection molding machine.

Table of Contents

- One of the effective methods to prevent wear in injection moulding machines is lubrication.

- The machine settings can be checked and adjusted, there by helping to minimise wear.

- Selecting the proper materials for the moving parts is important as well.

- Cooling and heating techniques are also essential to help the moving parts last longer.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI