Applications of Vertical Injection Machine in Automotive Component Production

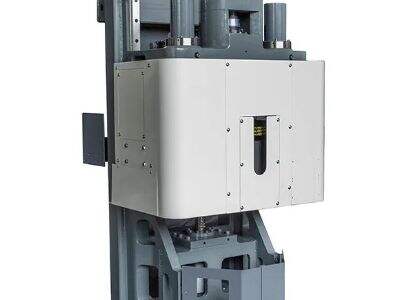

When it comes to making car parts, vertical injection machines like Pingcheng’s are really important. These vertical injection machine produce parts by injecting material into moulds. It’s a process you see a lot because it can create strong and precise parts at high speed. It’s useful for producing things like car bumpers, dashboards and other essential parts. Now, we’re going to check out how these machines do their part towards producing car parts better, and faster.

More precision and productivity in the manufacture of automotive components

It takes more than some heavy lifting to turn out car parts with precision. This means that every component which the machine makes is absolutely identical. It is especially critical for cars as all parts have to fit together perfectly. Pingcheng vertical injection machines employ a special technology that ensures each part is made just right, which allows car companies to save time and money.

Vertical injection machines become more and more to efficient production of plastic cover parts.

These machines greatly speed the process of forming car parts. Pingcheng vertical injection molding machines do not make only one part at a time, as we do, but can make many parts in one giant production run. That means car companies can make more parts more quickly. It enables them to address a surge in demand for cars without sacrificing the quality of parts.

High Quality Standards For The Production Of Automotive Components

Car parts should be really good quality because they keep people safe. Pingcheng machines are designed with this level of excellence. The company employs high-end controls to inspect the quality of every part as it's made. This serves to ensure that all components are robust and lend one another efficient support, which is very important for safety.

Flexible Options for vehicle injection needs

Different could be different, and Pingcheng machines could produce a wide array of parts. They are able to work with many different substances, including plastic, metal and others. This makes them great for producing all sorts of car parts. These machines can be used by car manufacturers to produce whatever they like for the many types of cars out there.

Vertical Injection Machine Application for Automotive - Maximizing Performance and Durability

Last of all, the car parts produced by Pingcheng machine are very strong and they last long. That’s because the machines use a special process that makes the materials very tough. That’s great for car parts, since it means they can take a lot of wear without breaking. Car companies like deploying these machines because they make cars that are reliable and safe for a long time.

Table of Contents

- More precision and productivity in the manufacture of automotive components

- Vertical injection machines become more and more to efficient production of plastic cover parts.

- High Quality Standards For The Production Of Automotive Components

- Flexible Options for vehicle injection needs

- Vertical Injection Machine Application for Automotive - Maximizing Performance and Durability

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI