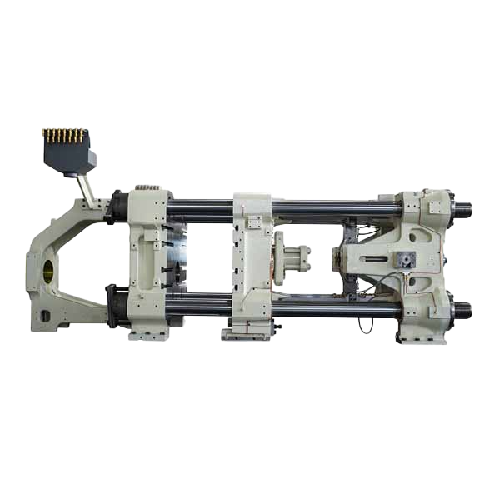

Injection Molding Machine is a special processing equipment used for manufacturing parts. This machine is also capable of generating products with irregular shapes, such as toys, plastic containers and even parts for automotive industries or airplanes. This system is actually quite useful as it fast-tracks the entire manufacturing process. Let us understand how this wonderful machine works.

Injection Molding: The plastic is heated up to a liquid form in an injection molding machine. This is quite a critical part seeing that the melted plastic are going to be shaped in the end product. The Liquid Plastic is Injected into a Mold is a hollowed-out block that produces the shape of an item and molds it into its corresponding impression. The plastic cools and hardens into the configuration of whichever product it was governed by. Then the Pingcheng injection molding machine gently pulls out the finished product. Finally when the product is fully dry it can be either painted or assembled with other parts.

They are very flexible too as these machinery enable in manufacturing with diverse molds for varied products. This way, for example if a factory manufacturer toy cars and wants to start producing car parts instead then this machine can do it on the fly. To quicken the process and save costs for making items, this flexibility offers single machine ability to make different kinds of products.

One of the greatest benefits that this Pingcheng machinery can bring is to help decrease waste. If they are manufacturing items they can re-melt warm accumulating plastic from previous remove to generate the next thing out of line. This not only keeps manufacturing processes more eco-friendly, finalized and even still recyclable materials are also used efficiently pulling that material out of upcoming waste streams.

In addition, these machines come in extremely user friendly which means they only require minimal labor force. This is a massive advantage as it helps keep the labor cost under control. The Pingcheng machines can make a lot of things at once over, so factories that utilize 3D printing are able to increase production without adding more staff. The vertical injection molding machine manufacturers really change the game in what we produce, making production easier and faster than ever.

One of the key benefits that these injection molding mechanisms bring to factories is the savings which can be generated as production costs. Factories were able to produce every product for a less expensive price with these machines. The vertical injection molding machines are designed to be extremely fast and accurate as a result, which means they need fewer workers in order for them to effectively.

Moreover, since these are machinery both the return of human intervention is very less in it. The same thing would also result in saving even more money at the factories level because there will be fewer workers to pay. This makes investing in injection molding machines a wise decision for any manufacturing company. These vertical injection molding machine price assist in lowering the product cost, and thus instead of cutting profit margins.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate Injection molding unit as soon as we can, and provide the best solution for your cost.

Our customer services is Injection molding unit. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Pingcheng now Injection molding unit and 50 technical staff with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the product's quality precise and steady. The machining and assembling of all important parts is monitored and traceable.

Pingcheng is committed to helping customers achieves their business goals through our Injection molding unit and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.