This will find out in this blog is what a gear box actually do. Gear box is a special kind of the machine and part of it which helps in moving power from one place to another. Think of it as an assistant that helps keep everything running smoothly. A wind turbine has blades -- big, wide parts that catch the wind & spin The gearbox takes the spinning energy which goes up to thousands of rotations a minute and sends it down about 30 times slower rms for control. So, the generator converts that power to electricity!

Typically, the gear box is at the top of a wind turbine near where it attaches to its nacelle. The nacelle is the part of a wind turbine that houses the generator and various other key components. It is absolutely important because it must be able to manage via a great deal of power and also energy. This means it has to be super strong and reliable, like some sort of superhero who ensures everything runs smoothly.

The gear box does this a little by speeding up the spnning and passing that enerby to generator. As a result, the wind turbine is able to produce more electricity with just that right quantity of blowing winds. Then the gear box — very important to realise wind more optimal, useful and efficient! This is a conduit that can link the power of wind with electricity we use everyday at home.

The cycle repeats, with a different set of gear boxes involved. The output from the generator is in alternating current (AC) form — it must be converted to direct current (DC) before interaction with large grid. It is similar to changing lanes on a highway so that you can arrive at the correct exit. The gear boxes can change the AC to DC, and regulate voltage so it is suitable for the power grid. This is highly crucial so that the electricity can be utilised safely and effectively.

It is still the case in transmissions and final drive gears because they have not been miniaturized yet, but new gearbox designs are using lighter and stronger materials to handle that problem without breaking. One more gear boxes have the ability to work even with no oil, which really save maintenance costs and make it easy use. It can also locate problems early with new sensors for less time off the job and lower repair costs. This allows wind turbines to continue operating and generating electricity without any interference!

By virtue of where they are located and the kind os stress that is put on a day-to-day basis, looking after wind turbine gear boxes can be difficult. One of the steps to making sure that everything works correctly is keeping gear box in good shape. This Includes: checking oil levels, cleaning the area dirthousekeeper and debris site properly to prevent damage And looking at the gear teeth for any signs of wear or damage.

The replacement of a gear box is very costly, so some companies are considering replacing only the broken parts rather than an entire gear box. This can save cost and the life of gear box. This is kind of like repairing a tear in your backpack instead of replacing the whole thing…it could be easier to keep gear boxes health by not just tossing them.

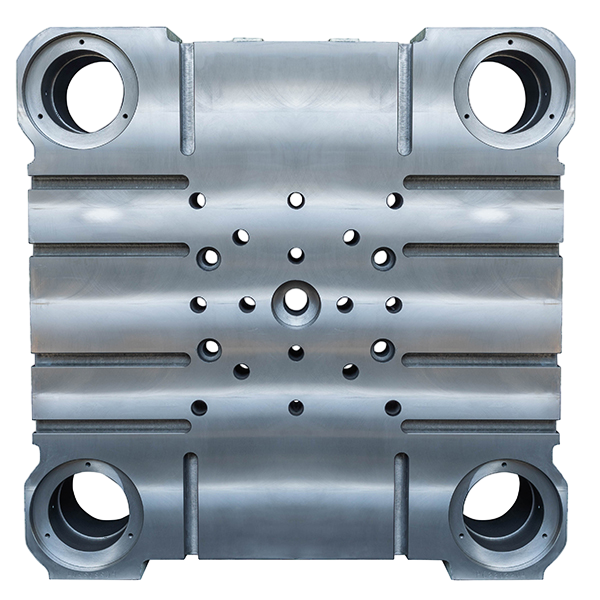

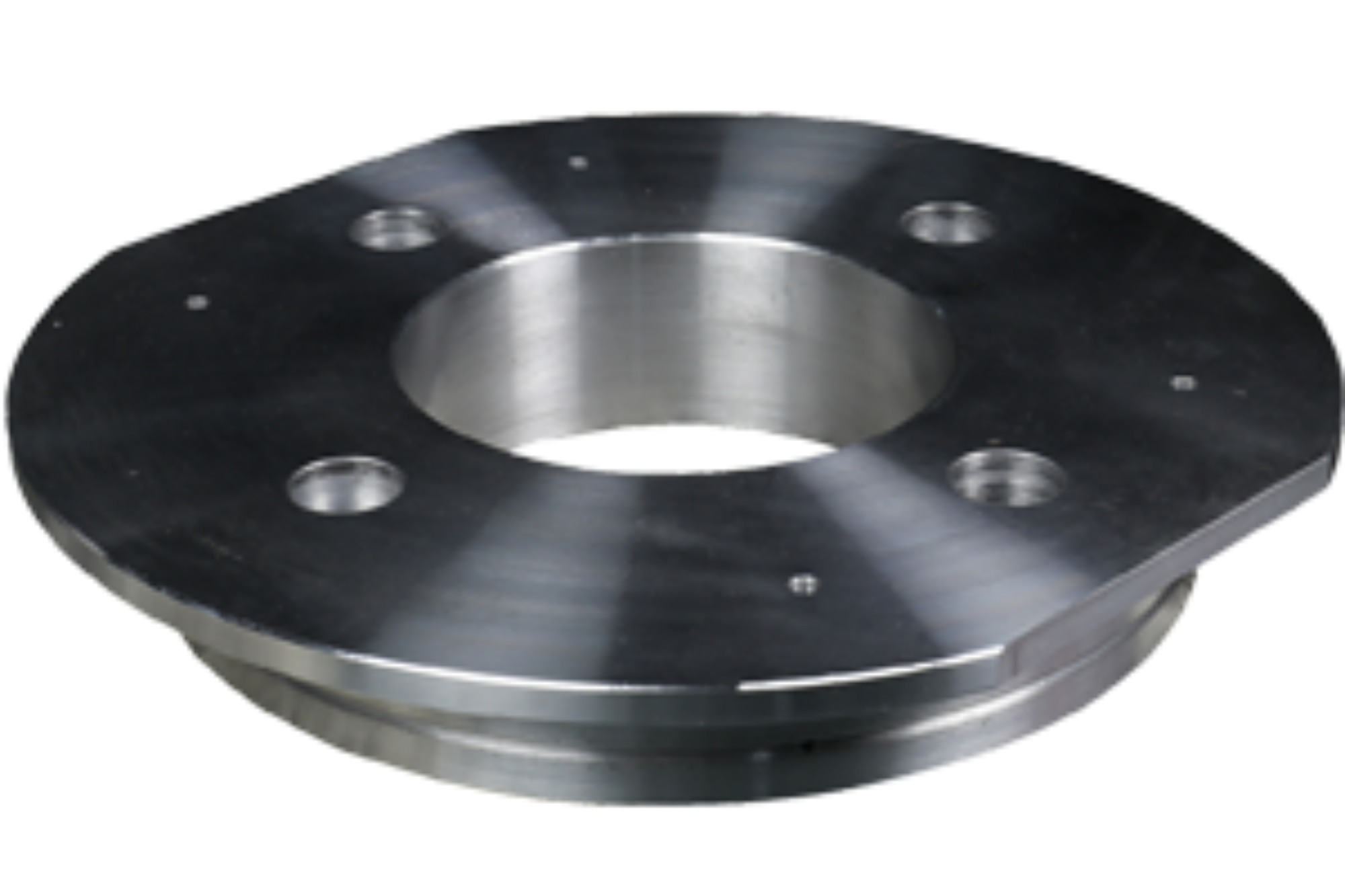

Pingcheng is now home to more than 20 manufacturing machines and more than 50 skilled technical staff. They gear box in wind turbine. Then the products are inspected by Mitsutoyo measuring tools and CMM that are periodically calibrated. Double-checking ensures that the quality of our products precise and stable. Every single component can be traced and monitored during machining and assembly.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate gear box in wind turbine as soon as we can, and provide the best solution for your cost.

The supply chain and services of Pingcheng is designed to assist customers reach their business goals. We focus on extending and gear box in wind turbine. PingCheng is the reliable manufacturer you're looking for. We are a partner which delivers options.

Our customers service focuses your satisfaction. We've been providing machining services and gear box in wind turbine with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.