Из описания может показаться, что редуктор ветрогенератора сложен для понимания, но когда вы упрощаете функции каждого компонента, все становится яснее. Редуктор — это уникальная машина внутри ветряной турбины. Его основная задача — заставить лопасти турбины вращаться быстрее. Когда лопасти вращаются с высокой скоростью, они могут производить огромные объемы электроэнергии, которую мы видим в домах и коммерческих зданиях повсеместно.

Это достигается при помощи коробки передач, которая использует ряд шестеренок, вращающихся вместе с лопастями ветряного турбина. Вращение лопастей начинает вращать большую шестерню. Затем она соединяется с меньшей шестерней. Система этих шестеренок связана таким образом, чтобы обеспечить вращение лопастей с более высокой скоростью. Это увеличение скорости чрезвычайно важно, так как оно помогает вырабатывать больше энергии, делая ветряной турбин очень эффективным.

Процесс покупки редуктора для ветрогенератора стал вызовом для многих людей, и это связано с тем, что при выборе неправильного редуктора для вашей системы привода может быть нанесён ущерб не только генерации электроэнергии, но и дальнейшее развитие может быть ограничено. Если редуктор слишком маленький, он не сможет справиться с мощностью, поступающей от турбины — и вы получите неэффективную систему, в лучшем случае. С другой стороны, если редуктор слишком большой, он может стать очень дорогим и неудобным в использовании. Это означает, что правильный подбор размера редуктора имеет большое значение.

Редукторы ветрогенераторов обычно работают правильно, но иногда происходят отказы. Распространённой проблемой может быть износ зубьев внутри редуктора. [Это может произойти из-за высокоскоростного вращения лопасти на сильном ветру. Без внимания это со временем вызовет проблемы.]

Чтобы избежать этой проблемы, необходимо регулярно проверять и ухаживать за редукторами до того, как ситуация станет серьезной. Это означает проведение регулярного технического обслуживания и проверок. Когда вы это делаете, это помогает обнаружить мелкие неисправности до того, как они превратятся в серьезные поломки — что способствует бесперебойной работе вашей ветроэлектростанции настолько плавно (и эффективно), насколько это возможно.

С учетом возрастающего стремления к более чистым, возобновляемым источникам энергии разрабатывается все больше новых технологий для дальнейшего повышения эффективности и надежности ветрогенераторов. Одной из новых и стратегических технологий являются системы прямого привода. Это очень уникальная система, так как она полностью исключает необходимость использования редуктора!

Превентивное обслуживание — это еще одна довольно инновационная идея. Новое решение использует датчики и Большие Данные для предсказания износа компонентов редуктора ветрогенератора. Использование этого подхода может помочь сократить простои турбины и расходы на обслуживание, обеспечивая тем самым надежную работу ветроустановок.

Pingcheng — это партнёр, обеспечивающий полный цикл производства и сопровождение на протяжении всего жизненного цикла изделия. Поставка продукции — лишь начало нашего партнёрства. Наша служба поддержки клиентов направлена на обеспечение вашего полного удовлетворения. Более 20 лет мы оказываем услуги механической обработки и выстраиваем тесные партнёрские отношения с производителями редукторов для ветрогенераторов. Опираясь на многолетний опыт и глубокое понимание отрасли, компания Pingcheng стремится предлагать своим клиентам честные и прозрачные цены. При получении технического задания мы анализируем чертёж с помощью специализированного программного обеспечения и предлагаем оптимальное решение по наиболее обоснованной стоимости.

Редукторы для ветрогенераторов Pingcheng разработаны на основе многолетнего отраслевого опыта и глубокого понимания требований рынка. Мы анализируем чертёж, создаём его цифровую модель с использованием специализированного программного обеспечения и затем предлагаем наиболее конкурентоспособную цену.

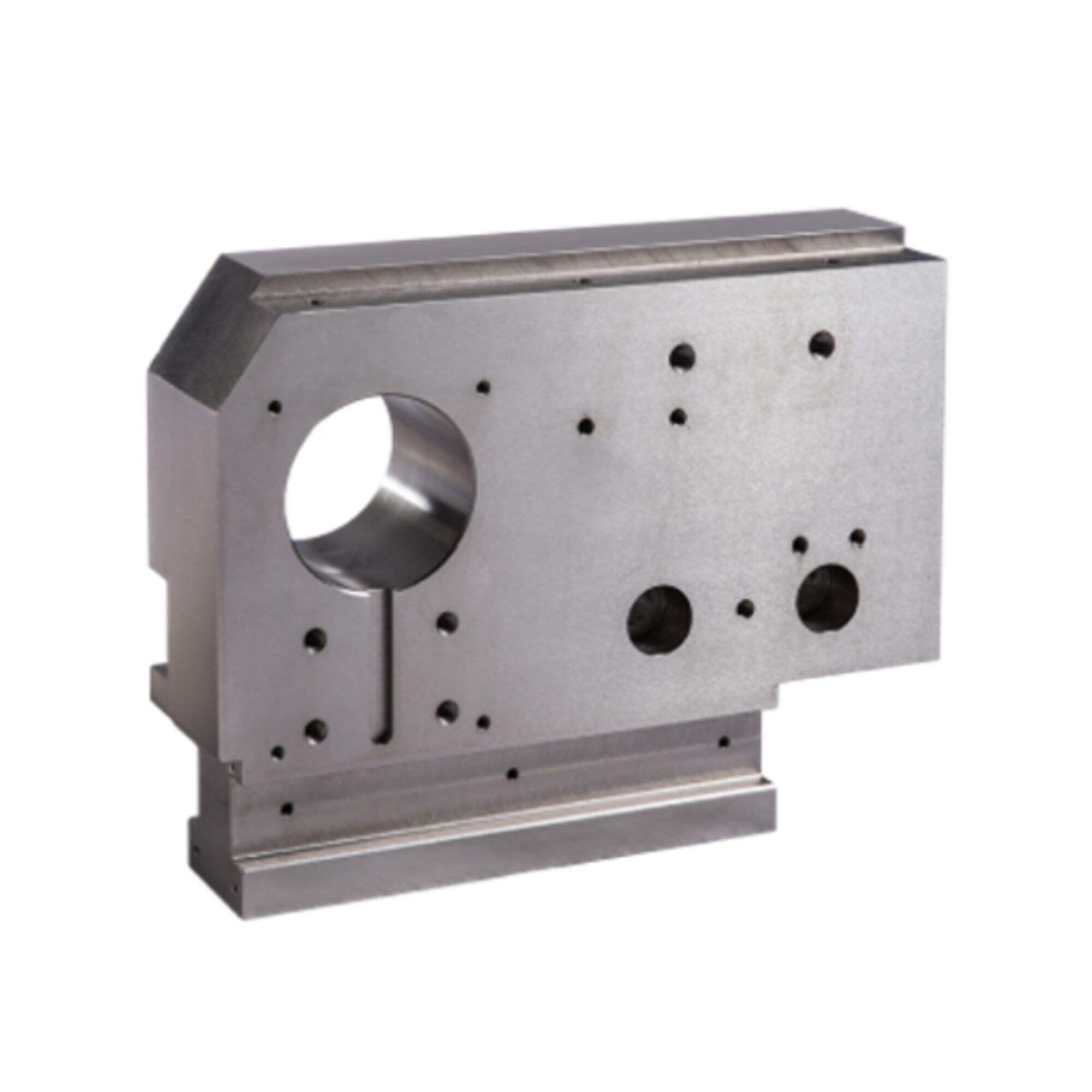

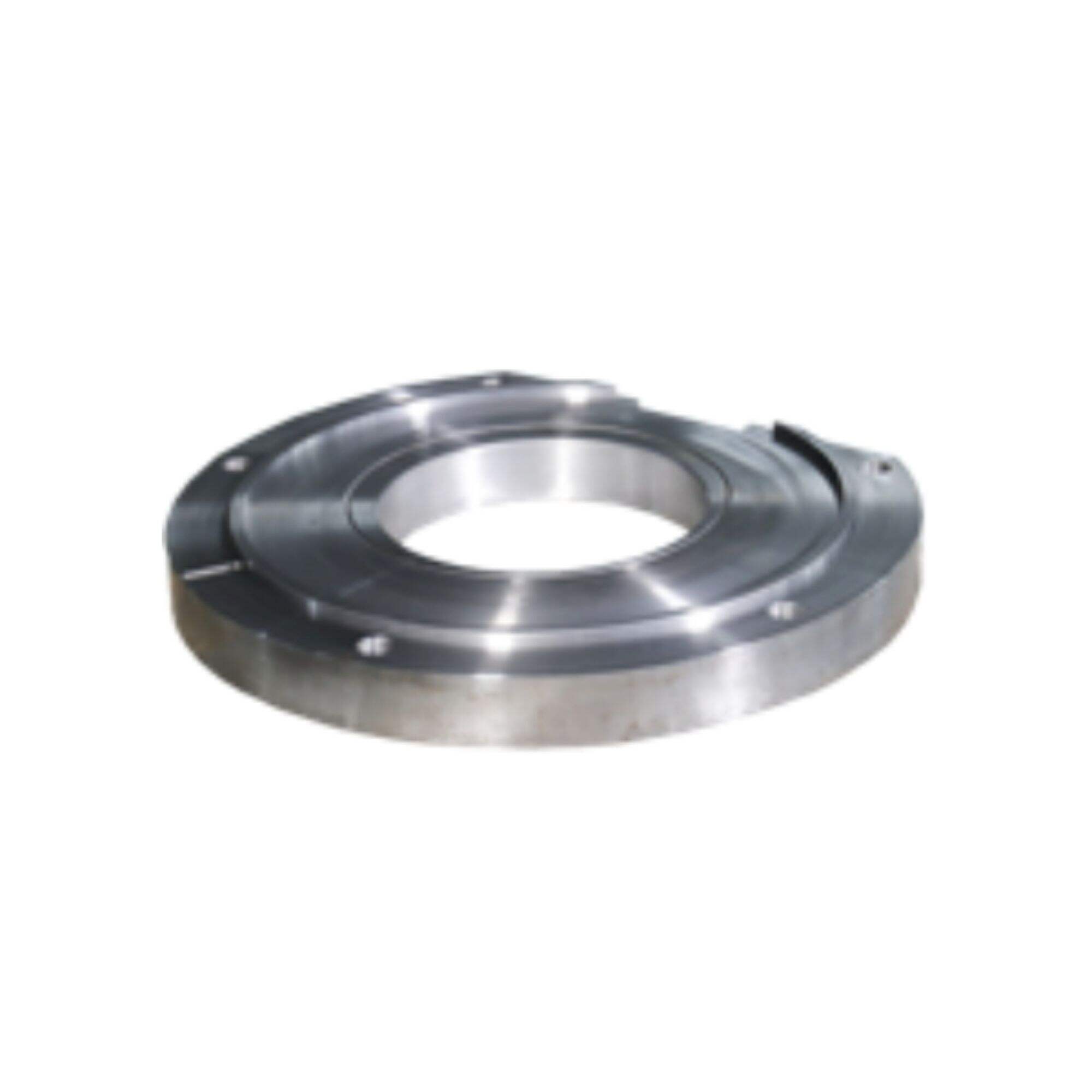

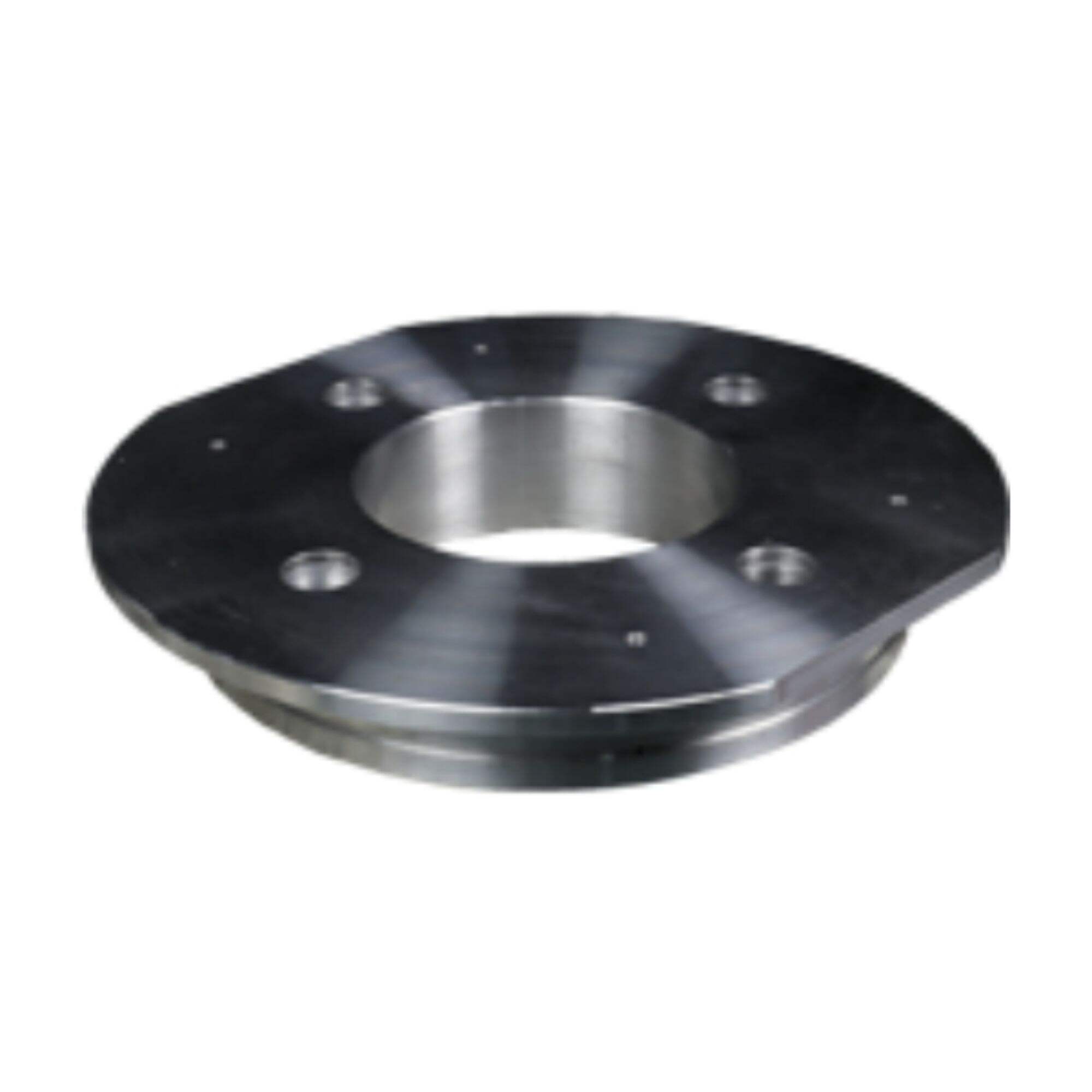

В настоящее время в Pingcheng насчитывается более 20 производственных площадок и 50 высоко квалифицированных технических сотрудников. Они занимаются производством редукторов для ветрогенераторов. Измерительные приборы Mitsutoyo и КИК подвергаются периодической калибровке. Двойной контроль обеспечивает стабильность и точность нашего качества. Обработка и сборка всех ключевых деталей находятся под контролем.

Цепочка поставок и услуги компании Pingcheng разработаны для того, чтобы помочь клиентам достичь их бизнес-целей. Мы сосредоточены на расширении и повышении потенциала и срока службы вашего производства. PingCheng — это редуктор ветрогенератора, который вы искали. Мы являемся партнёром, предлагающим возможности.