Честно говоря, вы когда-нибудь видели ветрогенератор? Это высокая башня с огромными вращающимися лопастями, которые приводятся в действие ветром для производства электроэнергии. Основная причина увеличения количества ветрогенераторов — это экологически чистое производство энергии. Но знали ли вы, как на самом деле работают ветряные турбины? Присоединяйтесь ко мне в изучении этой интересной темы!

Внутри ветряной турбины находится редуктор. Но редуктор играет ключевую роль. Он помогает передавать энергию от лопастей ротора к генератору, таким образом преобразуя её в электричество. Шестерни и другие детали объединяются для создания редуктора, который функционирует. Эти детали заставляют лопасти вращаться быстрее и преобразуют энергию ветра в электричество, которое мы можем использовать в наших домах и школах.

Ветряные турбины某种程度ной степени фарс — учёные и инженеры просто не могут прекратить улучшать их работу. Они хотят разработать лучший редуктор — вещь, для которой изначально была создана турбина, но с которой возникают большие трудности. Экономия веса, достигаемая за счёт использования более лёгких материалов для улучшения редуктора (и увеличения пробега на единицу топлива), становится очевидной. Когда зубчатые колёса изготовлены из лёгких материалов, они вращаются быстрее. Это препятствует износу зубьев, что означает, они могут оставаться прочными гораздо дольше и в конечном итоге требовать меньше ремонта.

Проектирование зубчатых передач с определенными формами является еще одним важным способом улучшения коробки передач. Эти уникальные формы позволяют зубчатым передачам работать плавно и с меньшей затратой энергии. Чтобы определить, какие из них лучше всего подходят для различных скоростей ветра, инженеры используют компьютеры для тестирования этих передач против нескольких геометрических форм. Таким образом, они становятся полезными для обеспечения того, чтобы ветряные турбины производили как можно больше электроэнергии.

Как и любая другая техника, ветряные турбины требуют обслуживания для поддержания их правильной и эффективной работы. Ветряные турбины обслуживаются техниками, которые проверяют коробку передач и убеждаются, что все в порядке. Это также время для проверки передач и убедиться, что все хорошо. После завершения этого этапа техники оценят наличие повреждений или износа, и если они обнаружат их, может потребоваться ремонт поврежденных частей или замена новыми компонентами для поддержания плавной работы турбины.

Форма зубьев на шестернях может существенно повлиять на то, насколько хорошо функционирует ветрогенератор. Шестерни с косозубыми или прямыми зубьями разных форм могут изменять способ передачи мощности и уровень шума, который они создают во время вращения турбины. Ученые изучают эти различные конструкции шестерен, чтобы найти способы повышения эффективности ветряных турбин и обеспечения их регулярной работы.

Например, некоторые новые научные идеи, которые исследователи изучают для продления срока службы шестерен, включают нанесение покрытий для предотвращения износа в определенных зонах контакта. Они также исследуют использование технологии трехмерной печати для производства индивидуально подогнанных шестерен, которые работают более эффективно с различными типами ветряных турбин.

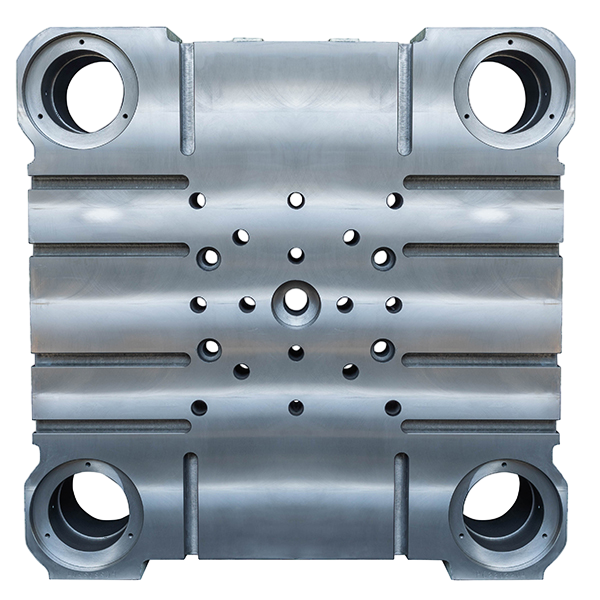

В Пинчэне сейчас расположено более 20 производственных мощностей и работает более 50 опытных технических специалистов. Они изготавливают редукторы для ветряных турбин. Затем продукция проходит контроль с помощью измерительных приборов компании Mitsutoyo и координатно-измерительных машин (КИМ), периодически проходящих калибровку. Двукратная проверка гарантирует высокую точность и стабильность качества нашей продукции. Обработка и сборка всех ключевых компонентов контролируются и прослеживаются.

На основе редуктора ветряной турбины и глубокого понимания бизнеса, компания Пинчэнг посвящена предоставлению своим клиентам справедливых цен. Когда мы получаем запрос на котировки, мы рассматриваем чертежи и проводим симуляции с использованием специального программного обеспечения незамедлительно, предлагая наиболее эффективные решения по справедливой стоимости.

Pingcheng — это производитель редукторов для ветрогенераторов и партнер по управлению жизненным циклом. Доставка нашей продукции — лишь начало наших партнерских отношений. Наша служба поддержки клиентов направлена на обеспечение вашего полного удовлетворения. Более 20 лет мы предоставляем услуги по производству и выстроили тесное сотрудничество с известными японскими компаниями. Приверженность Pingcheng справедливым ценам основана на многолетнем опыте и глубоком понимании этой отрасли. После получения запроса на коммерческое предложение мы анализируем чертежи в передовой программе и предлагаем наиболее эффективное решение по наиболее обоснованной стоимости.

Pingcheng помогает в достижении бизнес-целей в области редукторов ветровых турбин, предоставляя собственные цепочки поставок и решения по обслуживанию. Мы сосредоточены на продлении срока службы и повышении ценности вашего производства. PingCheng может стать надежным поставщиком, которого вы ищете. Мы являемся достойным доверия поставщиком, который может предоставить вам возможности.