Hi kids! Learn more about Double Stroke Cylinders here! A cylinder - this works just the same as a cable, except its moving up and down. It can be best visualized as a tube that slides linearly in one direction by scaling and then down again. Now a double acting cylinder can move both ways and this is extremely important. It can therefore attracts or repels. As you can imagine, dual stroke cylinders are purposeful for a wide array of tasks due to this capability!

Dual stroke cylinders are great because it consumes low energy compared to other cylinder types. By saying that they are energy efficient, what we mean is these can carry out all the work but require less power from machines for doing it. Which is very important considering that less power means a whole lot of positive for mother earth. It saves energy, making it saving air too. Clean air is healthy for everyone in our community — and its good for the environment also.

Dual stroke cylinders are unique for its versatile nature to do a variety of tasks. For instance a factories are using them to shift heavy items from one place to another. Do you picture some big machines hoisting and hefting boxes that seem like they must be about a million pounds? Dual stroke cylinders can also be used in hospitals to aid with breathing machines, such as the breathe better machine for improved airway relief. They even find a home in submarines! These cylinders can also be placed underwater yes to perform a variety of tasks. They are easy to use and can be employed for various roles, so being very valuable there.

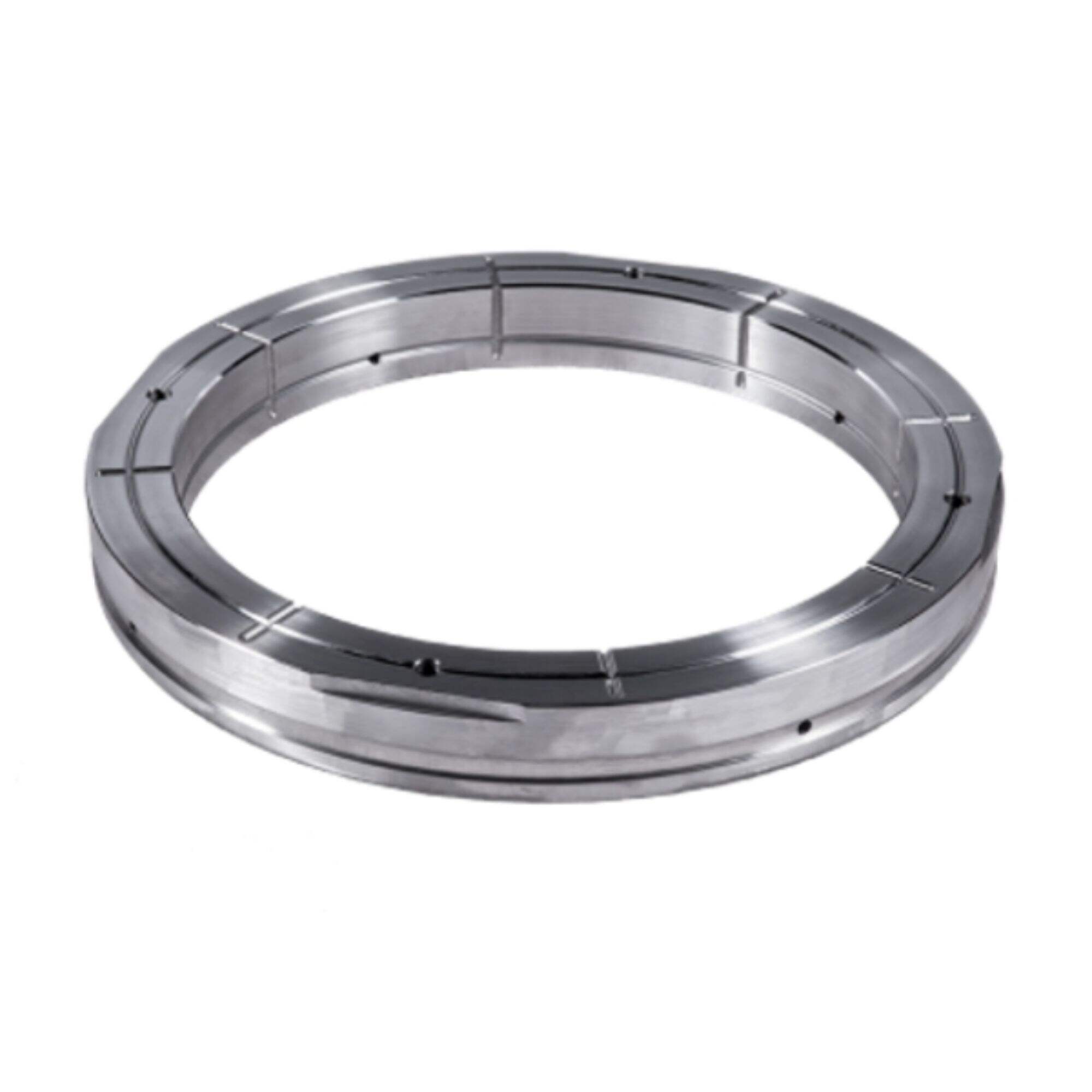

But, how do they really function these ingenious dual stroke cylinders? These work by pushing back an forth using either air or specialized fluids. What moves the cylinder is airflow that pushes in, or liquid flow that ever? These cylinders are designed to be extremely durable, and they will generally be constructed from rugged materials like aluminum or steel. This is the reason why these materials withstand a lot of power. They tend to have long life durations before breaking down or getting damaged. Isn’t that cool?

Dual stroke cylinders have a whole lot of great reasons to use them in various jobs. They are not only efficient, in the sense that they have low costs of production and use few resources to produce a given level of output fast) but also flexible-they can perform many different tasks. To the fact that also we know for sure they will work. This is why they serve as an appealing solution for a lot of businesses and industries. They save energy, they move heavy stuff and people see them breathe. Dual stroke cylinders are a natural marvel and is too playing with us greatly important in our life.

Based on dual stroke cylinder and a deeps understanding of the business, Pingcheng dedicated to providing its customers with a fair prices. When we receives a an inquiry for quotes, we look at the drawings and simulates using special software immediately, and offer the most effective solutions with a fair costs.

Our customer services is dual stroke cylinder. For over a decades we've offered services for machining and developed a close cooperations with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based on decades of experience and a deep understanding of this fields. When we receive a an inquiry for a quote, we review the drawings and simulations in our specialized software as soon as we can, and provides the most appropriate solution at an affordable prices.

Pingcheng is dual stroke cylinder achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

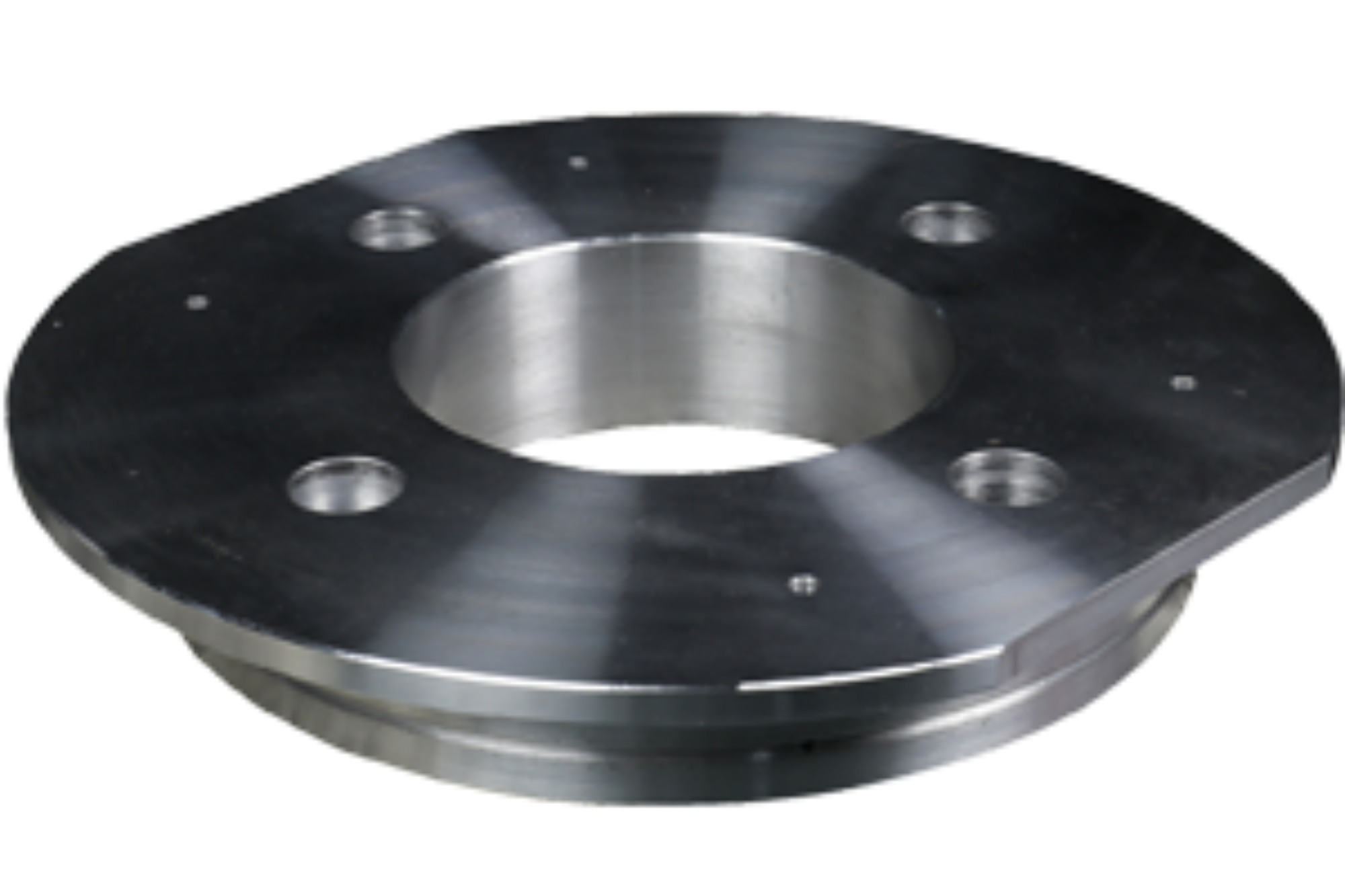

Pingcheng has now more than 20 manufacturing machines and dual stroke cylinder with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.