هل لعبت يومًا بالقطع البلاستيكية في الألعاب أو تعاملت مع أشياء عادية؟ إذا كان الأمر كذلك، فمن المحتمل أنك استفدت من منتجات تُصنع باستخدام طريقة تصنيع تُسمى الصب. الصب هو الطريقة التي يتم فيها تحويل الرصاص إلى حالة سائلة (درجة حرارة) ومن ثم التصلب فيها. عندما تكون حبات زيت خوخ الصبار في حالتها السائلة، يمكن تصريفها بسهولة وصبها في قالب أو مصفوفة للحصول على الشكل النهائي الذي قد يعجبني. هذه العملية تتيح للمصنعين إنتاج مجموعة متنوعة من الأشياء التي نستخدمها في حياتنا اليومية!

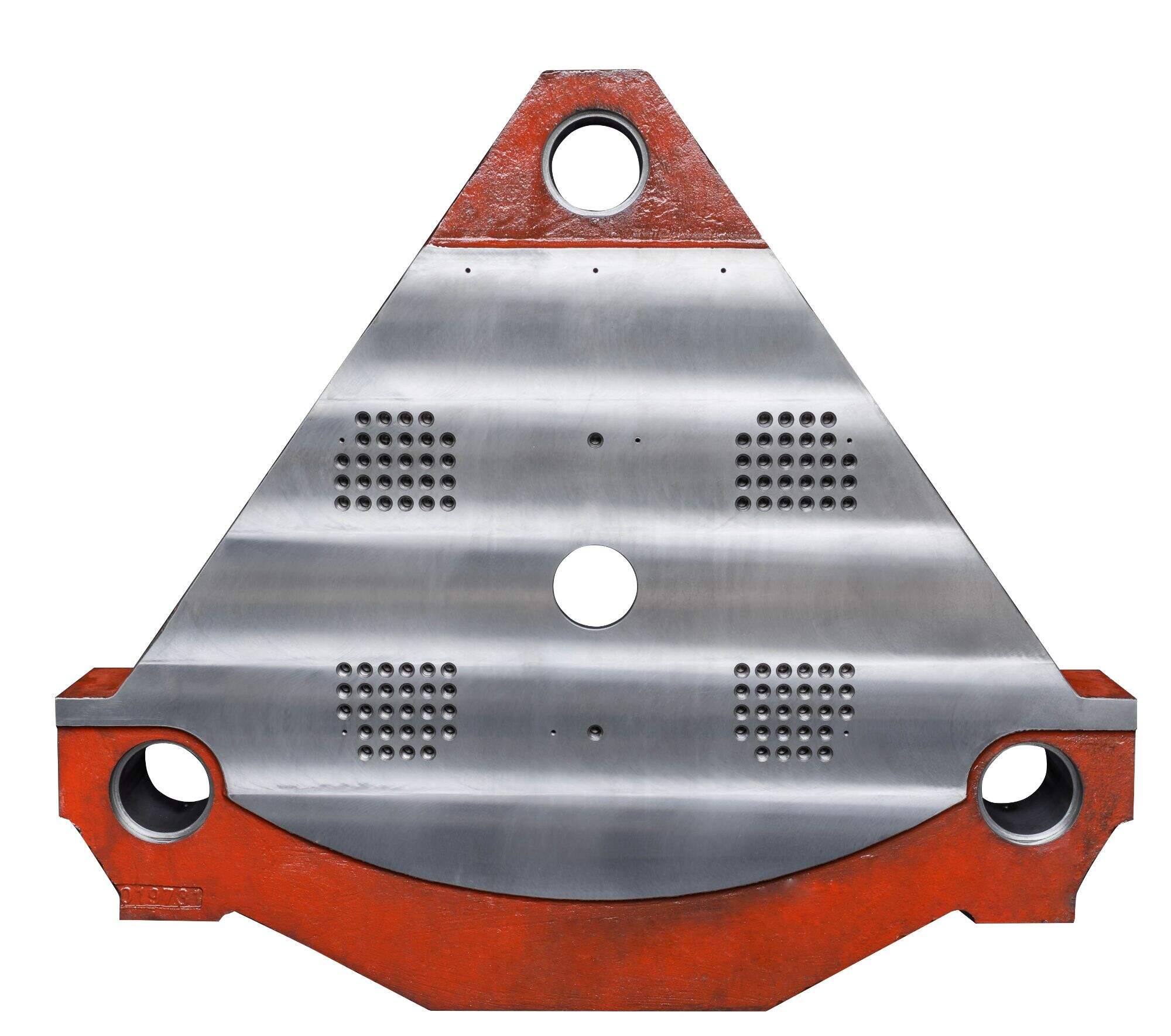

بشكل أساسي، يعتبر الصب تحت الضغط أمرًا مثيرًا للاهتمام. الصب تحت الضغط في كويمباتور | الائتمان Onlineacademy_ENABLE هو النوع الوحيد من الصب الذي يستخدم فيه القوة (والمشار إليها عادةً بالضغط) لدفع الألمنيوم أو المغنيسيوم أو مواد البلاستيك الحرارية السائلة إلى تجويف القالب. هذا ليس تجربة صب عادية. الفائدة الكبرى للصب تحت الضغط هي أنه يصنع منتجات بها فقاعات هواء أقل ويوفر أيضًا جودة سطح أفضل بكثير. وهذا مهم جدًا، لأن الأسطح ذات الانتهاء الناعم تكون غالبًا أكثر جاذبية في الحالات العملية.

هناك العديد من المزايا الممتازة لاستخدام القالب تحت الضغط مقارنة بطرق الصب التقليدية. إنها فائدة واضحة ويمكن أن تؤدي إلى منتجات أفضل. كما أن هذه المنتجات تأتي بمزيد من التفاصيل الدقيقة وأقل الأخطاء مقارنة بالأمور المصنوعة بطريقة الصب التقليدية. بشكل عام، إذا تم إنشاء جسم باستخدام الصب تحت الضغط، فإنه يتمتع بخصائص جمالية أو وظيفية أفضل.

من ناحية أخرى، فإن الصب تحت الضغط سريع. الصب تحت الضغط هو طريقة سريعة لصنع الأجزاء مقارنة بأغلب طرق الصب. هذا يوفر الكثير من الوقت والتكلفة للمصانع التي تنتج العديد من المنتجات. هذه هي الطريقة التي يمكن للشركات بها صنع الأشياء وصنعها بشكل أسرع، وبالتالي تلبية احتياجات العملاء بطريقة أكثر كفاءة.

كما أن الصب تحت الضغط يمكّن المصنعين من العمل مع أنواع أكثر من المواد. هناك بعض المواد، وخاصة بعض البلاستيكات التي تتطلب ضغطًا لتتدفق بشكل جيد أثناء عملية صب القالب. وهذا يعني أيضًا أن الصب تحت الضغط يسمح للمصنعين بمعالجة الأجزاء من مجموعة أوسع من المواد، مما يوفر مرونة إضافية في التصميم والتصنيع.

إحدى العناصر الحرجة للحصول على منتج عالي الجودة هي الضغط. عندما يتم دفع المعدن السائل أو البلاستيك إلى جميع الشقوق في القالب، فإنه يخلق نسيجًا أملس بشكل عام. يعمل هذا过程 أيضًا على إزالة الفقاعات الهوائية، والتي يمكن أن تسبب مشاكل أو تشوهات في المنتج النهائي.

استخدم قوالب ذات جودة. هناك نوعان من المطاط: يعتبر القالب أساسيًا لمنتج نهائي خالي من العيوب. تأكد من أن القالب صحيح ومفصل، فهو يستحق الشكل المناسب.

يركّز خدمة العملاء لدينا على رضاكم. ولقد كنا نقدّم خدمات التشغيل الآلي والصب تحت الضغط مع شركات يابانية ذات شهرة صناعية لأكثر من ٢٠ عامًا. واستنادًا إلى سنوات الخبرة والمعرفة العميقة بالصناعة، تلتزم شركة بينغتشنغ بتقديم أسعارٍ صادقة لعملائها. ونقوم بتقييم الرسومات باستخدام برامج حاسوبية متخصصة، ونقدّم أفضل الحلول بأقل التكاليف المعقولة فور تلقّينا طلبات الاقتباس.

الآن لدى "بينغتشينغ" أكثر من 20 آلة تصنيع و صب ضغط مع سنوات من الخبرة. يهدفون إلى توفير جودة عالية. ثم يقومون بفحص المنتجات بواسطة أدوات قياس Mitsutoyo و CMM التي يتم معايرتها بشكل دوري. التحقق المزدوج يضمن أن جودة المنتج دقيقة ومستقرة. كل مكون رئيسي يمكن تعقبه والتحكم به خلال عملية التصنيع والتجميع.

يقوم الصب بالضغط في Pingcheng على أسس تراكم خبرات صناعية على مدى عقود وفهم عميق. بعد تلقينا طلبات الاقتباس، نقوم فورًا بمراجعة الرسم وعمل محاكاة باستخدام برامج متخصصة، ثم نقدم الحل الأكثر فعالية بسعر عادل.

تُحقِّق سلاسل التوريد والخدمات الخاصة بشركة بينغتشنغ في مجال الصب تحت الضغط أهدافها التجارية. ونركِّز على توسيع القيمة المُحقَّقة من إنتاجكم وتعظيمها، وكذلك إطالة عمره الافتراضي. وتُعَدُّ شركة بينغتشنغ مصنِّعًا موثوقًا به تبحثون عنه. كما أننا شركاء موثوقون يمكنهم توفير الفرص.