In order for the HVAC system to function correctly, it requires a variety of components, including one known as an accumulator. Pingcheng accumulators holds any liquid refrigerant that the evaporator coil did not turn into vapor. The liquid refrigerant is kept in the accumulator until it is required by the evaporator coil for system functioning. Issues with low pressure related to the accumulator have become increasingly prevalent in the air conditioning and heating industry. There could be various reasons for this problem in your system: Refrigerant leaks might cause the pressure in the accumulator to decrease excessively. If a leak is present in the system causing your refrigerant to slowly escape, you will eventually experience low pressures and an under charge that triggers a specific mechanism. Malfunction of the Thermostatic Expansion Valve (TXV), a critical component for controlling the amount of refrigerant that enters the evaporator coil, can result in significant damage. An ineffective TXV that is not passing refrigerant may result in low pressure at the accumulator. Clogged filter drier hinders removal of moisture and contaminates from refrigerant. Over time, the filter drier may become blocked which could lead to limitations in refrigerant flow and lower pressure readings at the accumulator.

Insufficient pressure in the refrigeration system's accumulator causes issues that prevent the system from functioning at its best. Identifying Pingcheng low pressure hydraulic accumulator is crucial to prevent costly repairs and minimize downtime. Here are 7 warning signs to watch out for. Inadequate Cooling or Heating: Low pressure in the accumulator decreases system efficiency, leading to less cooling or heating output than required. Low Pressure: Inadequate refrigeration component construction can cause an accumulation of excess moisture, resulting in water pooling around certain areas. Elevated Humidity: Excess moisture levels may signal diminished pressure within the system, potentially causing damage to your goods and equipment. If the refrigeration compressor is running constantly for extended periods, it may be due to low pressure in the accumulator. The compressor needs to exert more effort to maintain the proper temperature of the contents. Frost, ice, and moisture are all not natural in a vapor system, but if you see frost or ice forming on the evaporator coil, it indicates low pressure in your refrigeration cycle. This happens when the evaporator coil operates at temperatures well below freezing. Reduced Airflow: This occurs when the system is not operating optimally, resulting in decreased air flow. Unusual Noises: Unusual sounds coming from the cooling system may indicate that low pressure in your air conditioning unit is the cause.

If you do find low pressure in your air conditioning system, there are various steps you can take to troubleshoot efficiently. Finding the cause of decreased pressure in an air conditioning accumulator. Check refrigerant levels to avoid low pressure in the air conditioning accumulator. Inspect the Pingcheng accumulator for hydraulic system regularly check the operation of your thermostatic expansion valve to prevent issues with refrigerant flow. Examine the Filter Drier: A blocked filter drier can limit the flow of refrigerant, causing reduced pressure on the accumulator side. Regularly inspect them and replace when necessary. Inspect the Compressor: A faulty compressor may result in reduced pressures within your accumulator. Thoroughly inspect the compressor and replace it if necessary. Searching for Refrigerant Leaks: Finding and repairing refrigerant leaks promptly will prevent low pressure issues in the air conditioning unit.

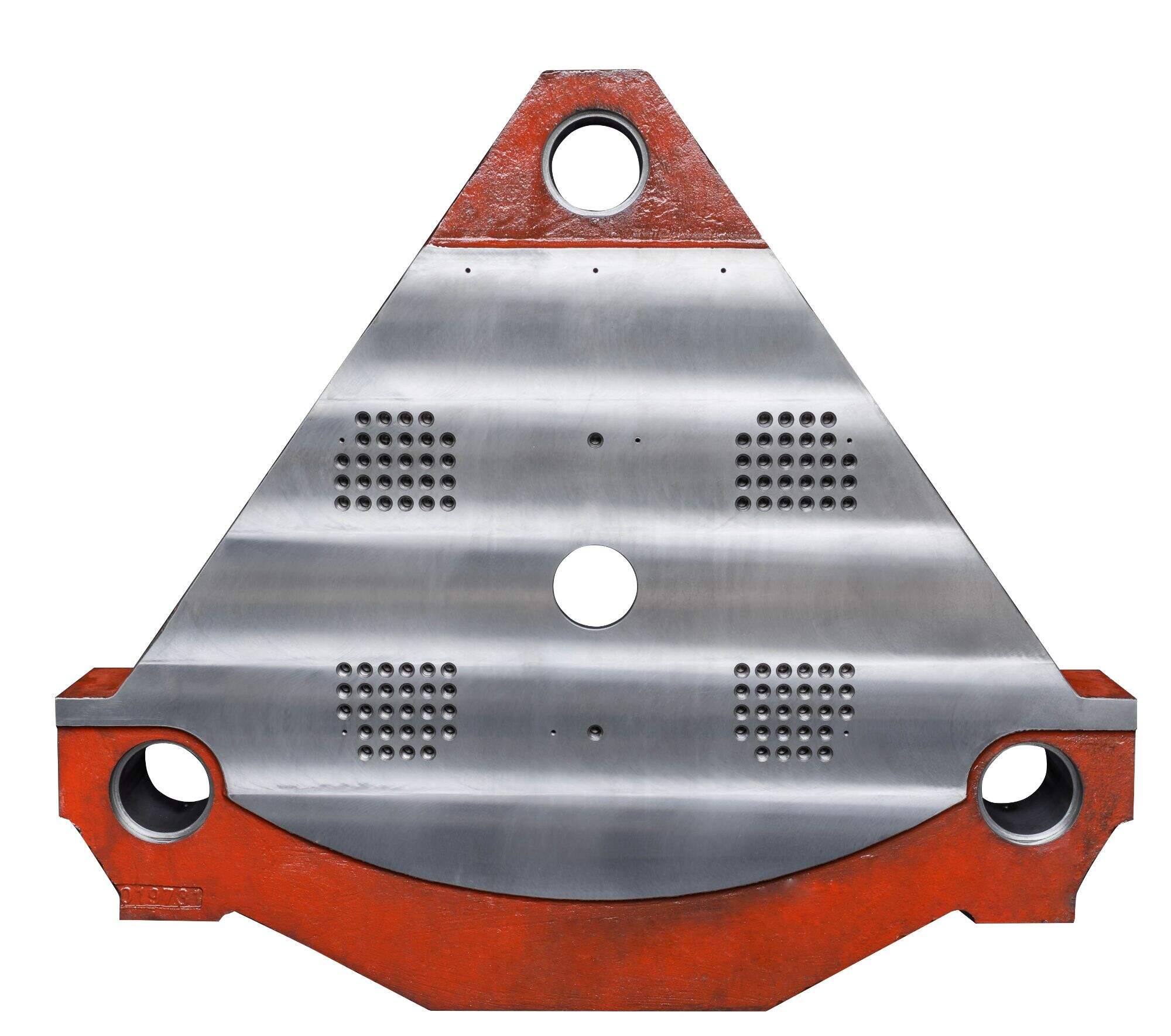

The accumulator is a crucial component in low pressure systems that is also necessary for ensuring fair operating procedures. Without the accumulator in the system, it would struggle to uphold its efficiency levels. This section contains the liquid refrigerant that has not yet been transformed into vapor by the evaporator coil. In the end, the Pingcheng pressure accumulator functions as a detector for distinguishing between vapor and liquid refrigerant. As refrigerant passes through the accumulator, the denser liquid refrigerant sinks to the bottom while vapor rises to the top. This space makes sure that only vapor reaches the compressor, instead of liquid refrigerant that could harm it.

Failure to take necessary precautions can lead to downtime and expensive maintenance costs due to low pressure in the accumulator. Pingcheng accumulator cylinder function in a complicated manner and rely heavily on the accumulator for efficient operation. Therefore, these issues present the efficient remedies for alleviating low pressure in industrial compressor systems. Identifying and repairing refrigerant leaks is crucial for ensuring the reliable operation of the system by addressing the main cause of low pressure on the accumulator side. Faulty parts: Low pressure can be attributed to a defective thermostatic expansion valve or compressor. It is crucial that these faulty components are replaced to help the system recover. Filter Drier: Knowing How to Examine and Maintain This part requires frequent inspection because it can block refrigerant flow and result in low pressure on the accumulator. Verify Refrigerant Levels: Insufficient refrigerant is a common factor causing low pressure, typically due to an under charged system. Regular maintenance service: Skilled technicians will conduct a routine system check to prevent low pressure problems and ensure proper functioning of industrial compressor systems.

Pingcheng is a Accumulator low pressure and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate Accumulator low pressure as soon as we can, and provide the best solution for your cost.

Pingcheng today has more than 20 manufacturing facilities and more than Accumulator low pressure. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We Accumulator low pressure as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.