Bearing housing pump is a main & effective component on which lots of the machines relays for liquid including Water or Oil to require its procedure at top rate. Which has reduced virtually on the method in which essential fluids movement by way of pipes and hence means really do what this impending gear box functions. But before we begin, I wanted to highlight the points that will be discussed in more detail mentioned above: what is a bearing housing pump and how basics of work (functionality + why you should maintain them regularly), selection factors for best-fitting your personal demands an example one issue if occurs can cause downtime at production plus some upgrades related with pumps new technology.

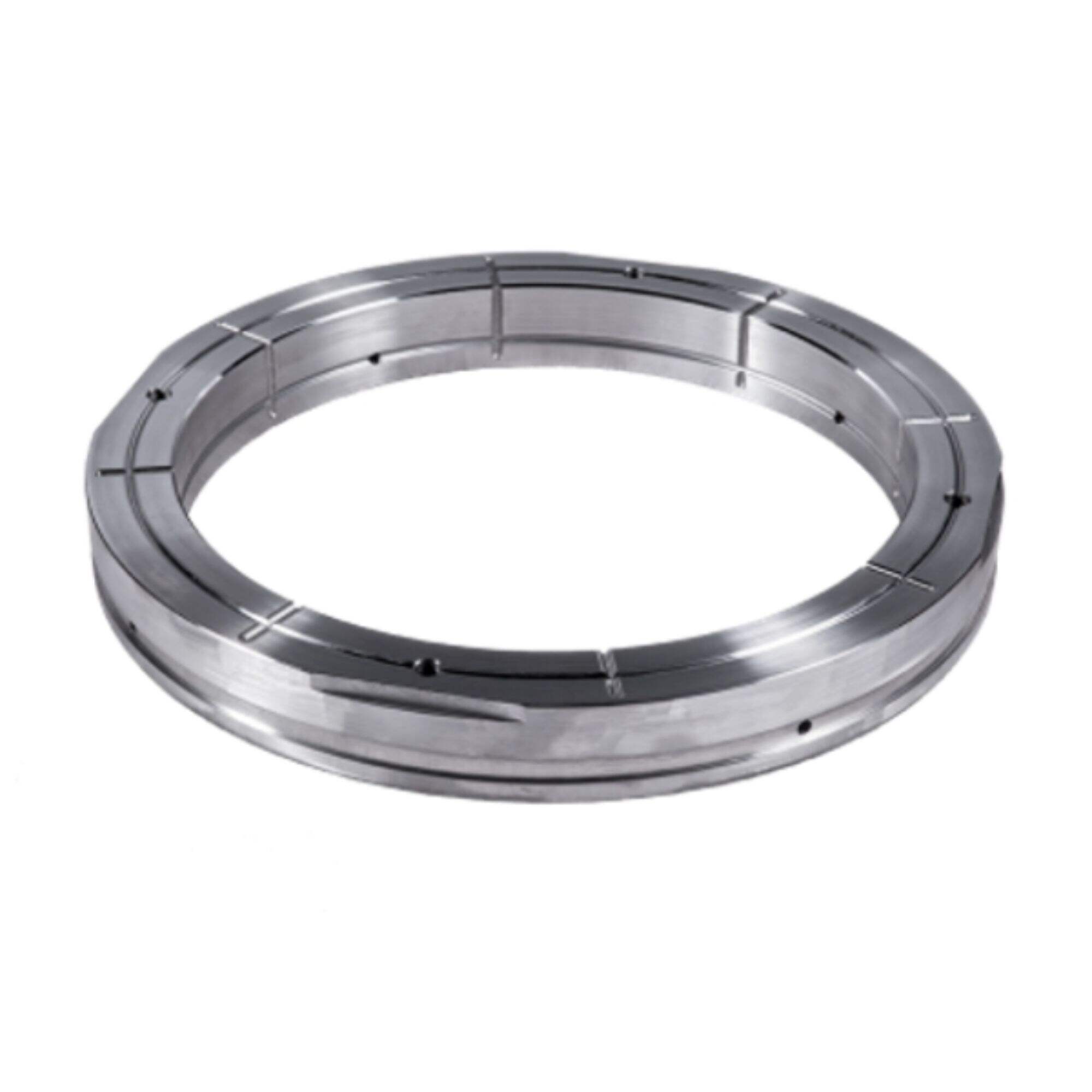

The basic job of a bearing housing pump is to help in the movement or circulation of liquids through pipelines. The pump in addition is valuable for helping to regulate liquid circulation or even hold the PSI (pounds per square inch) of Force at exact values as set forth by that equipment it has been manipulating. The most important item consist the impeller that give motion to fluid;housing for bearing, itself supporting shaft and a seal device as means of separating internal part from launched external flow or boundary between clear fluid &load supported lubricantsupported bearings.

The bearing housing pump is no different from any other machine requiring routine upkeep for it to work correctly. This care conventions varies on all observations and replacing of oil, cleaning the pools, checking for any damaged part in it etc.for proper alignment. Here are Some of the Common Tasks That Must Be Performed Regularly Not Performing these regular maintenance tasks can lead to a reduction in performance,higher levels of wear-and-tear and may cause pump failure. SEE RELEVANT SERVICE TIMES AND OTHER SPECIFIC ACTIONS FOR YOUR USAGE

How To Select Your Bearing Housing Pump

There are three main points in the choice of bearing housing pump. These parameters include fluid pumped, flow rate & pressure to be attained, pump operating environment as well as your specific application needs. In both cases, it underscores why you need to be able to create a pump configuration for yourself - rather than just finding the one-size-fits-all solution.

Like we have read earlier, bearing housing pumps are machines and hence can create a number of troubles over time. The most common malfunctions are causing a leak, all the pump is lurking leaking,lubricants in various pumps and other components wear over time including bearings of motor driven class impellers as well. Some reasons why these problems happen is as improper installation, poor maintenance by not proper maintaining them or they become old. Most of this, fortunately, is changeable through some small quick fixes or by simply replacing a few parts.

Upgrading to a premium (Read: high-performance ball bearing housing pump so as to benefit from... increased flow rates, improved OPEX and less frequent failuresimiranjamzari [CC BY 2.0], via Wikimedia Commons Well if that were too mild a whimper to generate you hair do center court, one can only hope for nothing good in the future... On top of everything weve already mentioned about usually very modern software packages involving all manners of bells and whistles like remote monitoring & control which might just save your erse when things go wrong Although specific requirements may vary and matters or argency around funding are different but idealyideally an upgrade is still worth thinking over.

Bear in mind a bearing housing pump is used for several machines and applications. Being able to use these water pumps, the importance of maintenance and picking your perfect type all go a long way in making sure that your equipment keeps running as efficiently and reliably as it can. Expediently solving problems as they crop up will also help save on bills an encouraging continuance is crucial to their reputation. Ensuring your investment works as hard for you as possible whether by upgrading to advanced pump tech or service best practices is key.

Pingcheng's bearing housing pump is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng is total process and lifecycle partner. The supply of the products is just the start of our partnership. Our customer service about ensuring your satisfaction. We've been providing machining services and building close partnerships with bearing housing pump for over 20 years. Based on decades of expertise and understanding of this industry, Pingcheng is dedicated to offering our customers honest prices. We examine the drawing with special software and presents the best solution the most reasonable costs when we receive offers.

The supply chain and services of Pingcheng are designed to help clients achieve their goals in business. We concentrate on extending and increasing the potential and lifespan of your manufacturing. PingCheng is a bearing housing pump you've been searching for. We are a partner which delivers opportunities.

Pingcheng is now home to more than 20 manufacturing facilities and 50 experienced technical workers. They bearing housing pump. Then, the product is inspected by Mitsutoyo measuring instruments and CMM that are periodically calibrated. Double-checking makes sure that the quality of our products precise and steady. The machining and assembly of all the key components are controlled and traceable.