Flanges are an essential part of industrial piping systems which are used to connect pipes, valves, pumps and other equipment. There are different types, and there are flanges for different applications and pressures In this article, we’re going to talk about the different flange types and their applications in your projects. Knowing these choices helps you determine the best approach for your special industrial requirement. Let’s enter flange world with Assembly, your professional supplier in industry manufacturing.

Various Types of Flange used in Industrial Pipe Work Essential Components of Piping System-Fittings - Elbows, Tees, Reducers And More [Happy reading English.

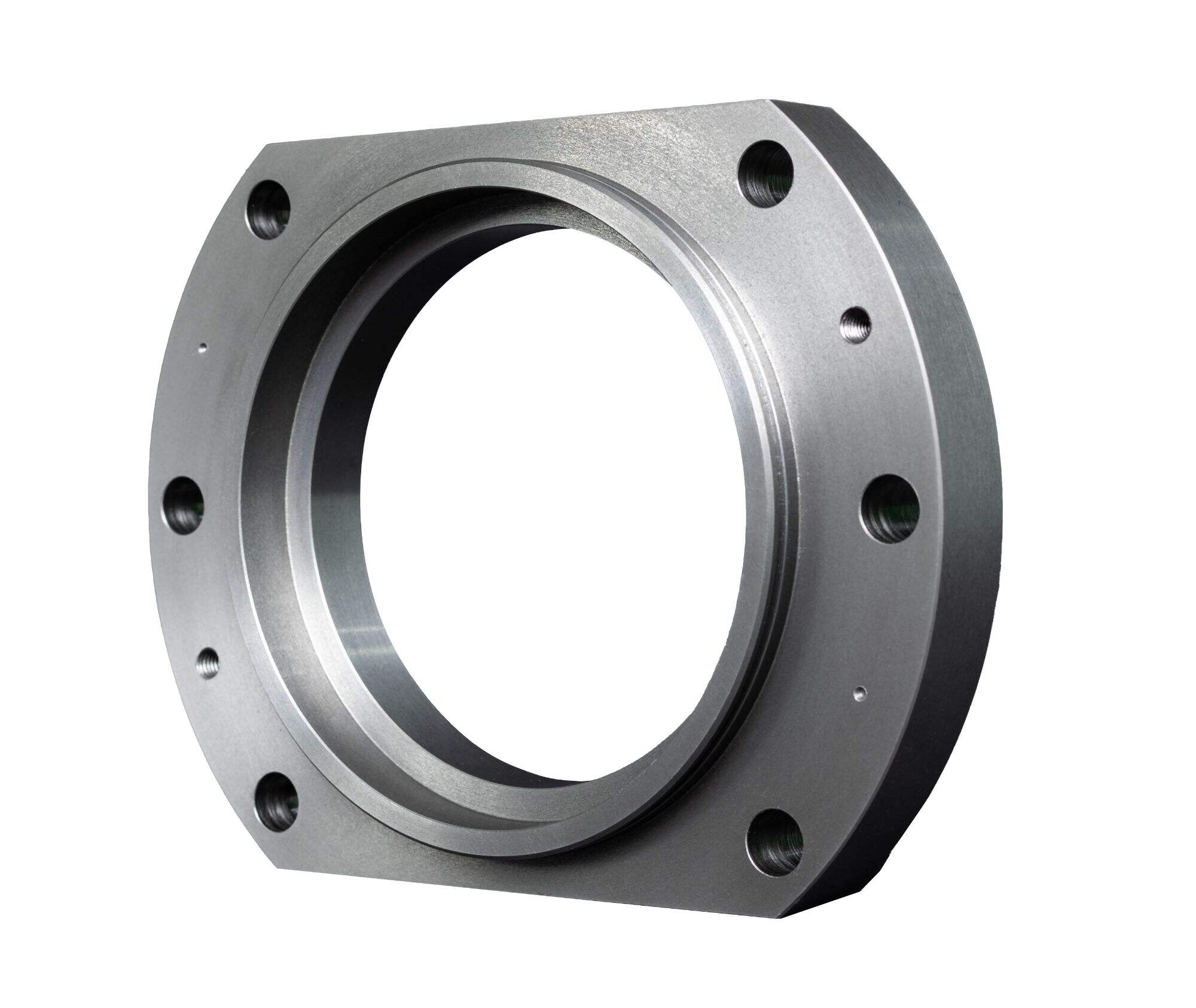

Piping or flanges used to connect sections of pipe, valve, or equipment. Highly Available Flanges: There are various types of flanges in use as mentioned below according to their application: Long Neck Flange: Long neck flanges are used when material of weld neck is to be welded to complete the joint. These are That flanges in large range of sizes, ratings, materials, and de-signs. Weld neck flanges have a long tapered hub and are often used for high pressure applications. Slip-on flanges are also a little easier to align than weld-neck flanges, because they have a little larger inside diameter than the through bore of the pipe. A blind flange is a solid disk used to block off a pipeline at the end of a piping system opening. Finally, threaded flanges are very much alike slip-on flanges, however, the bore is threaded so as to connect with pipes that are threaded on the outside.

Correct type of flange is based on pressure, temperature and type of fluid of the pipe. For instance, stainless steel flanges are suitable for corrosive conditions and carbon steel flanges are suitable for high-pressure and high-temperature circumstances. You must select a flange with the material and style required for your application to ensure the correct combination of safety and efficiency.

Applying the right flange type can make for a much more secure and long-lasting piping system. For example, weld neck flanges have great strength and they are the least prone to leakage among the flange types. Slip-on Flanges, however, is advantageous because of its lower price, but it’s easy to align. All the flange types have certain properties which are particularly beneficial and knowing these can help with your choice when it comes to your construction.

It's important for wholesale purchasers to find flanges that are able to be purchased in mass quantities without sacrificing quality or breaking the bank. In Pingcheng, our range of flanges are suitable for a variety of applications across industry. Our flange quality is top of the line at an excellent price. Whether you are looking for bulk flanges for a large-scale build or a particularly style for an industrial project, Pingcheng have a selection that caters for that.

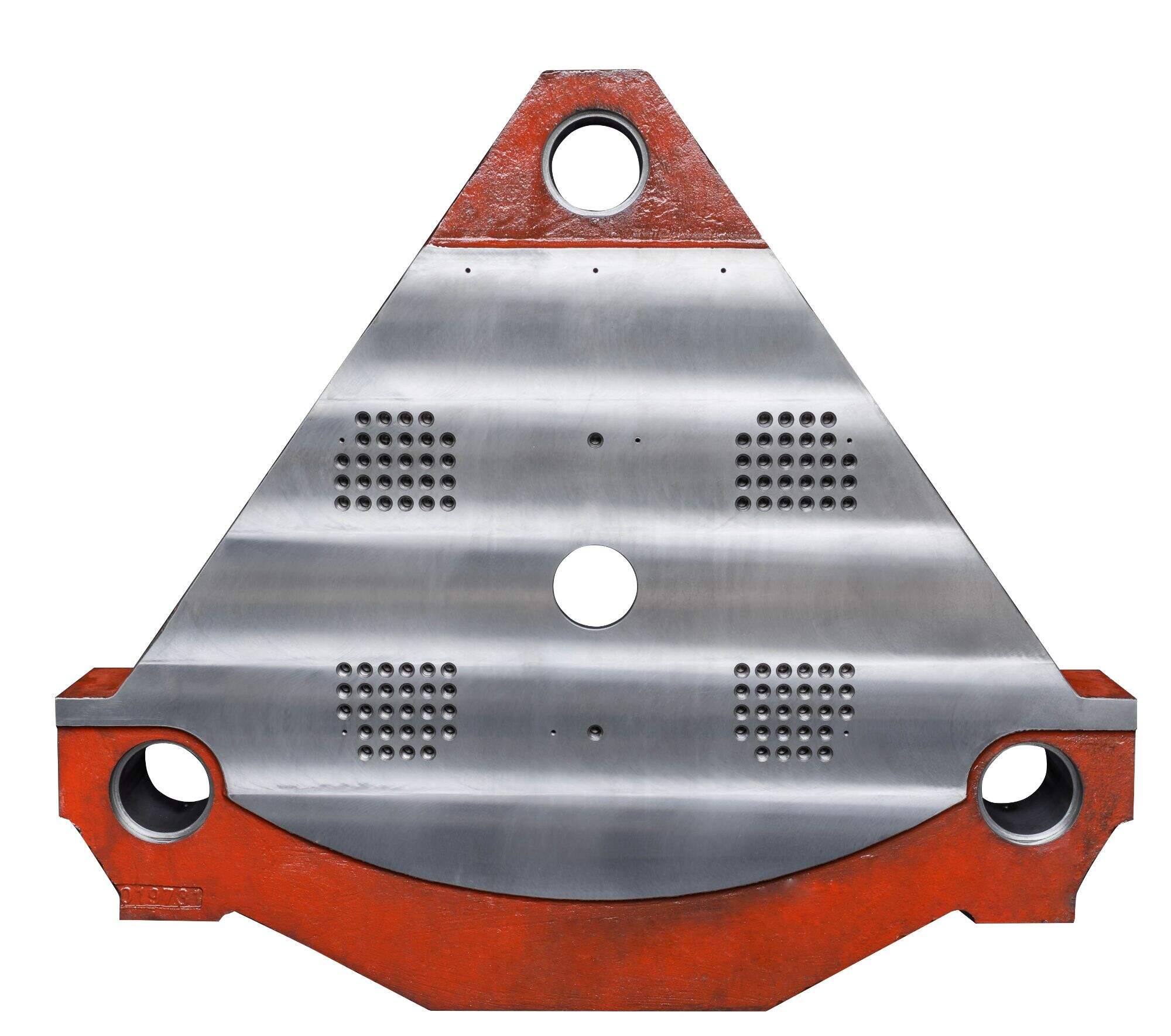

Pingcheng's different types of flange is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng is a full-service and different types of flange. The shipping of our products is just the beginning of our partnership. Our customer service about ensuring your satisfactions. For more than 20 years we've provided manufacturing services and have built close collaboration with well-known Japanese companies. Pingcheng's adherence to truthful pricing is based our decades of experiences in the industry and understanding this sector. We analyze the drawing in special software and present the best solution at an affordable costs once we have received an inquiry for quote.

Pingcheng currently has more than 20 manufacturing equipment and different types of flange. They seek to offer high quality. Mitsutoyo's measuring equipment and CMM are periodically calibrated. This double-checking ensures that our quality is reliable and accurate. All key parts are traceable and monitored during machining and assembly.

The supply chain and services of Pingcheng are designed to aids clients achieve their goals in business. We different types of flange as well as maximizing the values and life of your manufacturing. PingCheng is a dependable manufacturer you are looking for. We are a suppliers that offers a variety of options.