Flanges play a crucial duty in linking pipes as well as tools in the large range of industrial atmospheres all over. All these components are relatively unsophisticated and consist of the flat sheets with holes drilled in just about every conceivable place for bolting down everything and sealing up all nice a tight. Almost as vast in selection is the range of flanges, that each has an equally specific use. To an addition of the Flanges world; Pingcheng different types of flange are even known as a product which is used in diversified areas.

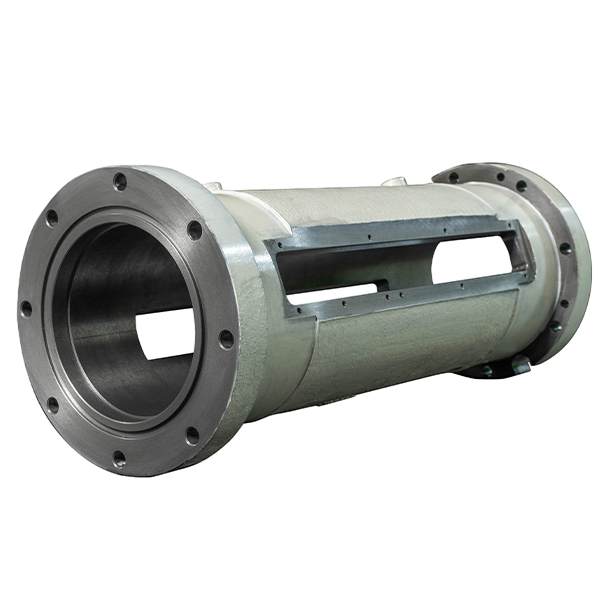

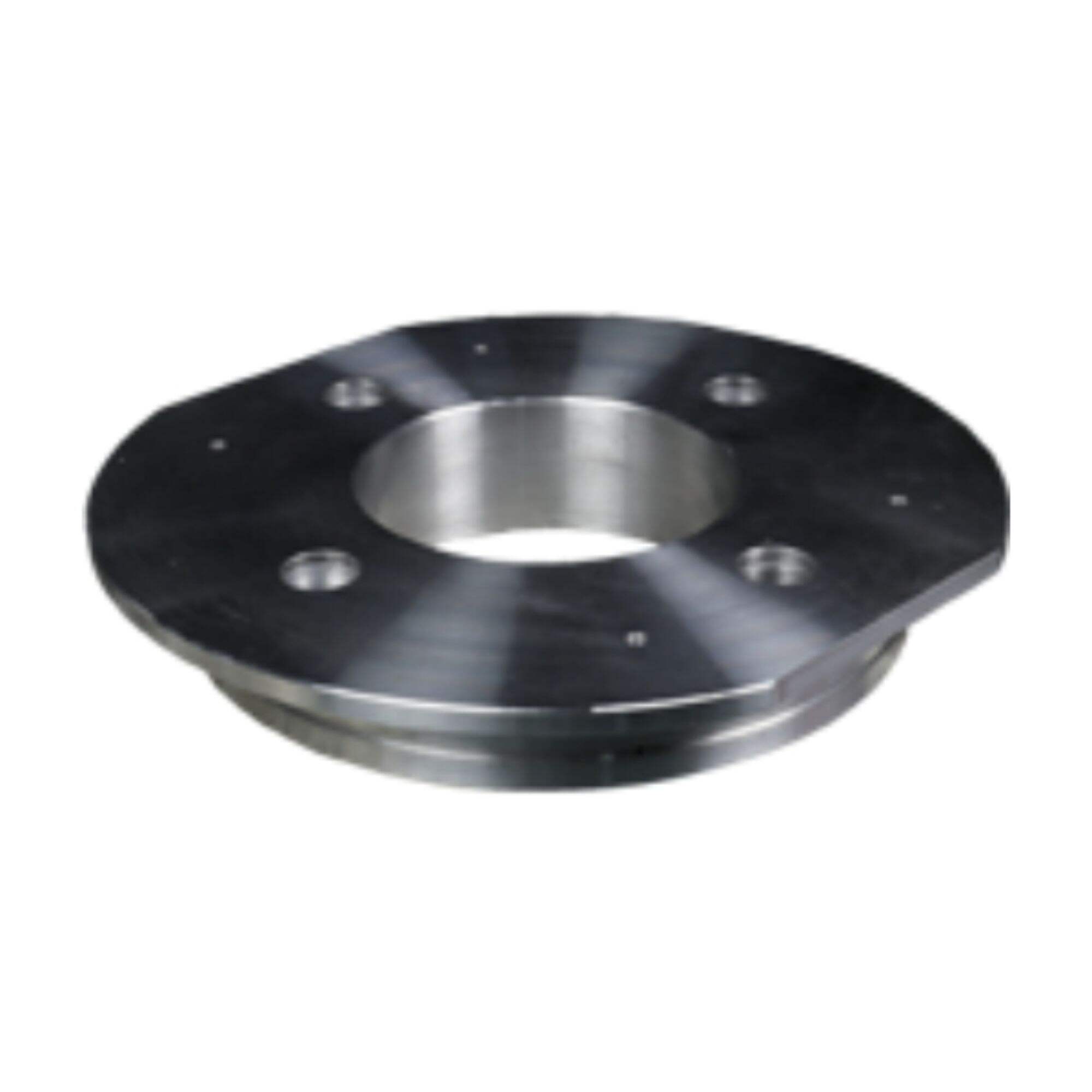

These On the other hand threading, slip-on, weld neck and blind flanges are some of the common types on industrial architect. Threaded flanges or any particular type of flange required for very quick and easy but not intended automate are used: Threaded Flange) Weld-neck to be used where the pressure is too large for slip-ons. Welding neck flanges, in contrast are designed for safety and function at high pressures. On the other hand, Used to shut down ends and close from pipe Run. *Blind flanges Flange Type has its own Advantages which accepts that Flange is required to be utilized as a part of all applications.

Pipeline systems are the most essential through which the liquids, gases and other things must be transported that are used or in need from one point to their destination. Flanges: While doing the operation of industrial process piping at various places like fabrication work or structure development, by using certain tools to deliver requisite fuels etc. in system and flange function as a sealant for joining two parts together required such systems vs. Slip-on are for use in low pressure applications only and weld neck can be used under heavy mechanical stress. In other words, Threaded Flanges (used in Gas Pipe) permit the flow of gases without blockage. However, blind flanges carry the greatest load as they need to cap and seal pipes or valves where liquid would escape. A Pingcheng base flange is therefore required to transport these materials safely, and thus the right one has been selected out by all.

A range of industrial segments like oil & gas, chemical and manufacturing rely heavily on flanges. That is why not all flanges can be used in every application, depending on the type and there are too many types. We could even start listing them but one of these threaded flanges is great for high-temperature applications. Pressure will also be lower and slip-on if fitting with appropriate bolts so they always remain installed its proper place. These weld neck flanges are used in a particularly high pressure and temperature environment. Meanwhile, they are the useful accessories that capping pipes and finishing pipe runs as well in order to enhance safety. Flanges are widely used, such as carbon steel flange, stainless materials and aluminum.

Flanges also vary as you go to different industries and are present only in those of a suitable style or size. Threaded Flanges Threaded flanges are always good for some other connection where a thread is been included, and it more suitable to use at low pressure & temperature services. This offers a right and secure path to join the pipes, whereas Socket weld flanges are effortless welding perfect for top pressure plus aeration pipe work that can be used by low-pressure application. Lap joint flanges - can be used often, so simply alter system that would need frequent adaptation Slip-on flanges are the preferred pick for low-pressure application if it hooks up such sort of pipes in order to carry fill out from chemical compounds or task liquids stream. Understanding the differences between these flanges can help determine which one will be best suited for your application.

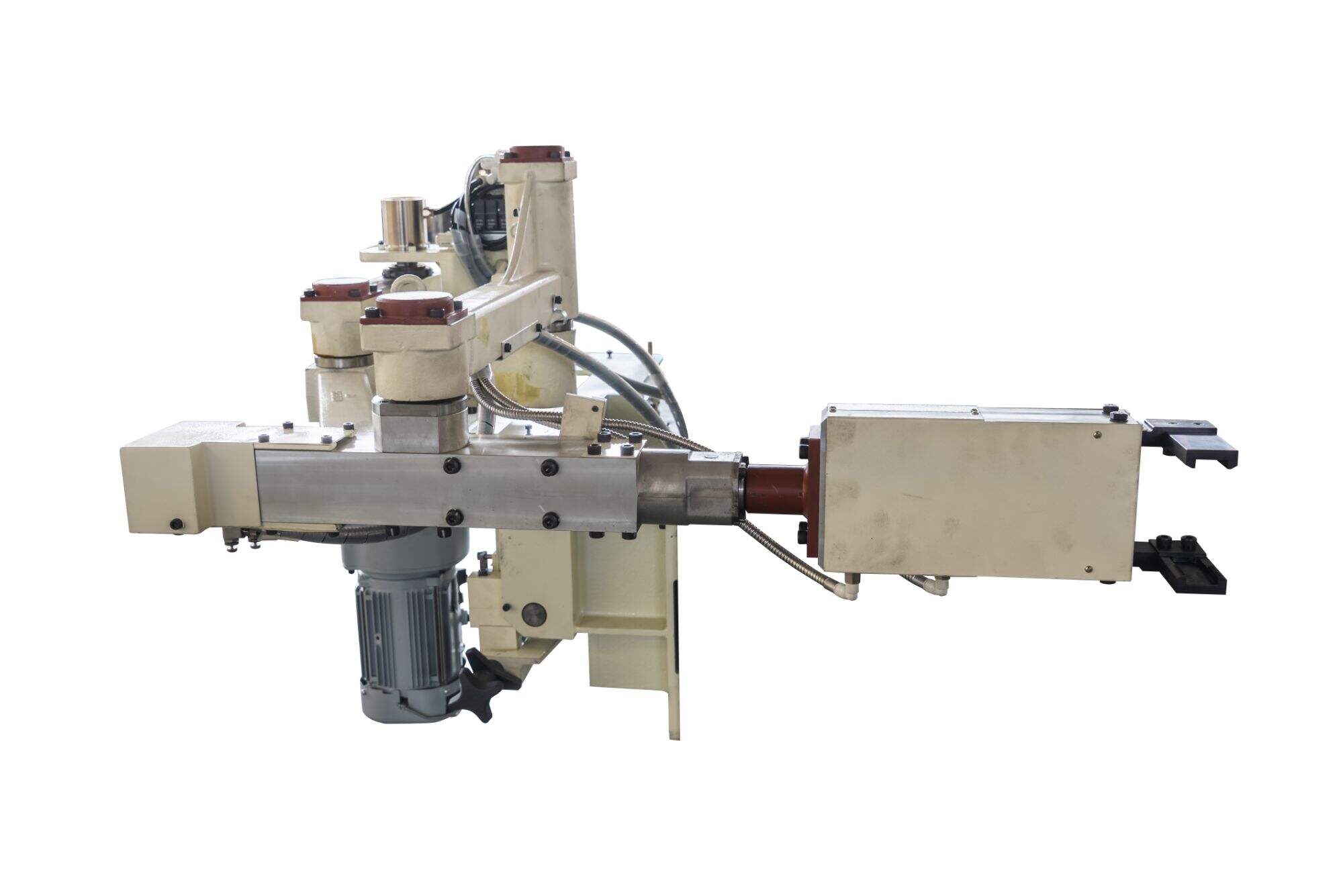

Therefore flanges can be said to be practically a part of the industrial application and usage with specially such connection where it is required for any system to work smoothly. If you are dealing in industrial processes, it is of utmost importance to make the right choice with Pingcheng flange bearing covers. All in all, dry flange-out seems to be a safe procedure, and one that even amateurs can undertake without risking too much downtime. Due the fact it only necessitates know-how from basic principles like already existing knowledge of how various parts cooperate with each other.

Pingcheng is Types of flanges achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Our customers service focuses your satisfaction. We've been providing machining services and Types of flanges with industry-renowned Japanese companies for more 20 years. Based on years of experiences and knowledge of the industry, Pingcheng is dedicated to offering our customers an honest price. We evaluates the drawings using special software and present the best solutions at the most reasonable costs once we have received requests for quotations.

Pingcheng today has more than 20 manufacturing facilities and more than Types of flanges. They aim at providing high quality. Mitsutoyo's measuring devices and CMM are regularly calibrated. Double-checking helps keep the accuracy of our products and steady. Every single component can be traced and monitored during machining and assembly.

Pingcheng's commitment for honest pricing is founded on years of experience in the industry and knowledge. After we receive the request for quote, we review the drawings and simulate Types of flanges as soon as we can, and provide the best solution for your cost.