The world of manufacturing has seen widespread improvement in how things are being made thanks to the technological advancements. One of them is the vertical plastic injection machine, a new invention that has changed the whole market. These are machines that have changed how molding of plastic materials is done delivering so many benefits to the production quality and efficiency.

Vertical plastic injection molding machines are quite unique as they using a vertical clamp and an injection unit that takes care of the mold from the bottom upwards. This design permits impressive tools for molding that is accurate and rapid-making top-quality products. Vertical machines; however, have a lesser flow path for the material compared to horizontal ones. This capability allows the molding process to be better managed so that a completely plastic parts can flow efficiently into their molds, thereby deliver superior production quality.

Not only this, their space-saving construction adds to the versatility of vertical plastic injection machines and makes them quite a choice for cramped manufacturing facilities. They have a small footprint being stationed closer to the production line, cutting off transportation time and limiting damage. The proximity allows for increased production quality as it shortens the time taken during manufacturing which helps optimize the workflow.

Efficiency is a major benefit of vertical machines This unique design runs on smaller mold sizes, therefore reducing cycle time which results in higher productivity. Moreover, vertical machines are easy to automate as they have been designed with minimal human intervention in mind. It sharpens uptime for automakers, giving them more labor to use in other ways which increases efficiency and production.

The vertical plastic injection machine has become one of the trending products in this manufacturing industry because it offers several advantages. Poonawala believes that these machines are a more sustainable solution since they demand less material and energy to be activated. Vertical machines also offer high accuracy, making it possible to produce complex parts with little scrap and less cost/effects on the environment

In summary, vertical plastic injection machines are changing the way manufacturers operate. This leads to high production quality, increased output and a faster manufacturing process due to their advanced features and capabilities. As technology advances, so will the concept of vertical machines in factories around the globe keeping people on their toes for new ideas and easier workflow to hit this industry running.

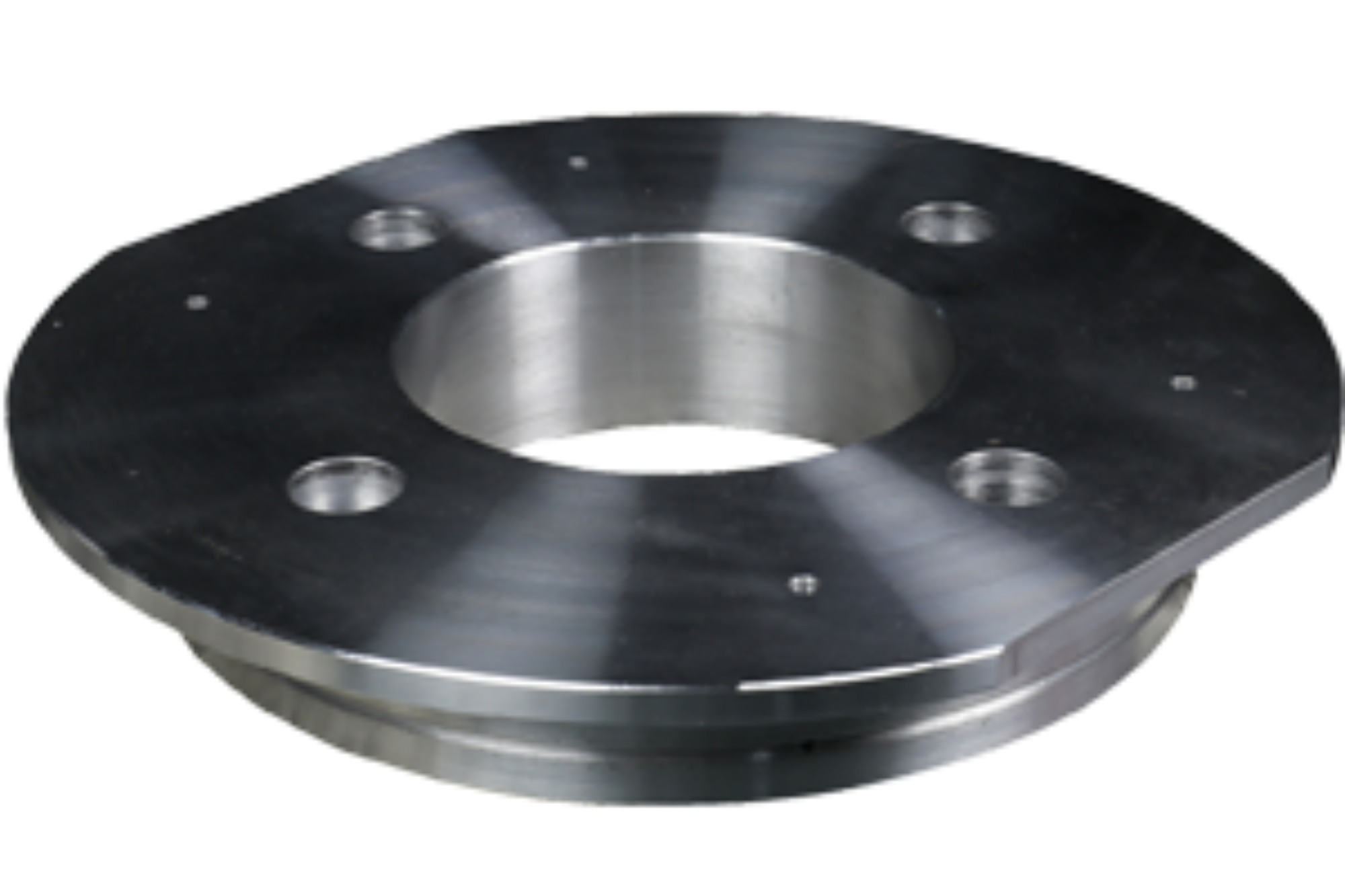

Pingcheng has now more than 20 manufacturing machines and vertical plastic injection machine with years of experience. They aim at providing high quality. They then inspect the products by Mitsutoyo measuring tools and CMM that are calibrated on a periodic basis. Double-checking ensures that the product's quality precise and steady. Every key component is traceable and controlled during the machining process and assembly.

Our customer services focused on your satisfaction. For over a decade we've provided machining services and vertical plastic injection machine with well-known Japanese companies. Pingcheng's adherence truthful pricing is based upon our years of industry experience and knowledge of sector. We analyze the drawing special software and offer the best solutions for an affordable price once we have received an inquiry for quotes.

Pingcheng's vertical plastic injection machine is founded on decades of industry experience and a deep understanding. After we receive quotation requests, we examine the drawing and simulate in specialized software right away, and then provide the most effective solution with a fair price.

Pingcheng is dedicated to helping customers vertical plastic injection machine by providing our supply chains and services solutions. We strives to help you extends and maximize the life and worth of your products. PingCheng is the reliable manufacturers you're looking for. We are a company that delivers potential.