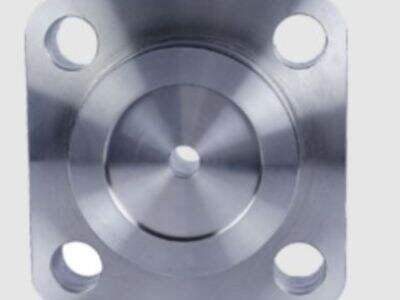

For producing multiple axis die casting parts, correct tools and methods are quite crucial. At Pingcheng, it come by integrating our machining solutions to ensure that we can machine complex pieces efficiently and accurately. Our state of the art multi axis machining capability allows us to both speed up production time and provide the very highest quality of part. This is particularly important for industries where precision matters, such as in the production of automobiles or aircraft.

How You Can Benefit from Multi-Axis Machining Solutions

We have specialized machines, at Pingcheng, that can climb in multiple directions. This is what allows us to make parts faster, because the injection mold machining is able to perform many steps without stopping. We are able to create a part from the beginning to end on one machine. This is a great deal faster than using multiple machines and rotating the part each time. It saves time and minimises the risk of errors.

Efficiency through Integrated Solution of Machining

Our machines are programmed to easily work with one another. This allows us to switch from one thing to the next without wasting time. If we have to drill a hole and then polish the part, our machines can do it in a seamless operation. This keeps out factory moving fast and smooth so we're able to produce a lot of parts that are awesome in less time.

High Accuracy Machining For die casting parts, precision machining is necessary

Some of the parts that we make are incredibly complicated. They could have holes, curves and edges galore. Our small molding machine are ideal for this because they can get to all different parts of the piece we’re working on. We’re able to do that because our machines can move in ways that no other machines can move.

Performance to the Max with Multi-Axis Machining Technology

Not only are our multi-axis machines fast, but they are also high in power. They’re designed to take on heavy materials and big jobs without wearing down. That means we can accept big jobs knowing that our hydraulic molding machine will be able to do the work properly. That’s so critical for our customers who are looking for dependable parts for their products.

Integrating into Quality Machining Solutions

Here at Pingcheng, we think a really good part is fundamentally a part that builds perfectly. Our end-to-end integrated solutions allow us to monitor the entire gamut from concept to completion. At every stage, we do quality control, ensuring that every element is up to our high standards. This is what keeps our clients happy and our reputation top of industry.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

SR

SR

SK

SK

SL

SL

VI

VI

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

GA

GA

CY

CY

IS

IS

KA

KA

LA

LA

MI

MI