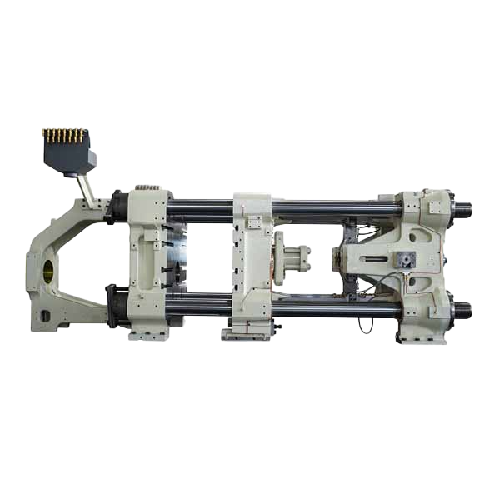

Hydraulic pressers are the workhorses of plastic and metal part manufacturing. These are the machines which make use of hydraulic pressure to give shape to materials. They are critical for a broad range of products, like car parts and household goods. At Pingcheng, we provide commercial-grade hydraulic moulding machines to cater to any production line.

We would like you to make an informed decision; we know that wholesale buyers require a durable and efficient industrial equipment to ensure the smooth running of their business. Our Molding Machines are constructed of high quality material and engineered using the latest technology to ensure they have a long life and optimum performance. We have machines in multiple sizes and capacities, so there is one suitable for whatever your production need may be.

With advance technology our hydraulic molding machines are more efficient in production. These machines have nuanced controls that allow you to shape parts accurately, minimizing waste and saving time. Energy saving devices and easy setting functions allows for the production without quality loss from Pingcheng machines. Link

Industrial machinery has to be tough. Pingcheng hydraulic presses are built to last in rugged environments. Constructed with durable materials and with rigorous manufacturing processes, you are assured of an exceptional product that will last and perform well every day. Its maintenance is easy, that is no flying saw, no groove for pile when producing, so they are easy for maintenance.It not only saves space, guarantees small radius of curvature of MD, but also reduces maintaining cost. Bearing Case

Other Choice, Other Solution For Your Manufacturingufflesc_14 our products(shell) open size:3118cm close size:18mediump:plastic,wire (and flocculus) our company hae 10years in product experience, the quality of this is really wonderful, we belive!!!

Whether congeneric, a small amount of propaganda (and the production lead encapsulated) to continuous operation, as long as the machines of various models, meet customer demand. We provide machines in various models with varying mold capacities, hydraulic pressures, and custom specialties. This range ensures that you will be able to find a machine that can be effortlessly incorporated into your present production line.

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They hydraulic molding machine. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Based on decades in experience and a deep understanding of the industry, Pingcheng is dedicated to offering customers a fair price. When we hydraulic molding machine, we examine the drawings and simulate using specialized software right away, and then provide the best solution for your price.

Pingcheng is committed to helping customers achieves their business goals through our hydraulic molding machine and service solutions. We concentrates on helping you extend the life and values of your production. PingCheng is the dependable manufacturers you're looking for. We are a company that delivers options.

Pingcheng is a hydraulic molding machine and lifecycle partners. The supply of the products is just the beginning of our partnerships. Our customer service is about ensuring your satisfactions. We have been offering the machining services and establishing a close partnerships with well-known industry Japanese companies for more than 20 years. Based on decades of experiences and knowledge of this field, Pingcheng is dedicated to offering our customers an honest prices. We examine the drawing with an advanced software program and then provide the best solution at a reasonable prices once we have received the requests for quotation.