Hello, young readers! Do you know the die casting process? This is a really cool process where molten metal gets poured into in order to shape it onto something special. How awesome is that to think about?! The metal is melted and molten, then when it cools down after that into the state of an item. This, however has a special process where you have to do this in order that the end result is awesome. This is one such way where the quality die casting can be a very special parameter, and we shall discuss more about it in this blog segment today.

After all, we put the hard work into our images… of course, you want them to last. You do not want it to break every quickly or wear out! This is the reason high-quality die casting matters so much. We can build really strong parts that are much better than any other by using the right techniques and materials. This makes them ideal for public use, and they are very resistant to wear and tear.

Another way to prevent them from being fragile, is the use of nice metals, such as aluminum, zinc and magnesium. Not only is this materials strong, it is also light and are great for creating complex shapes that are as hardy and user-friendly. Like a toy or one part of a car which are able to play and not easy to broken, so that quality die casting can makes the things better.

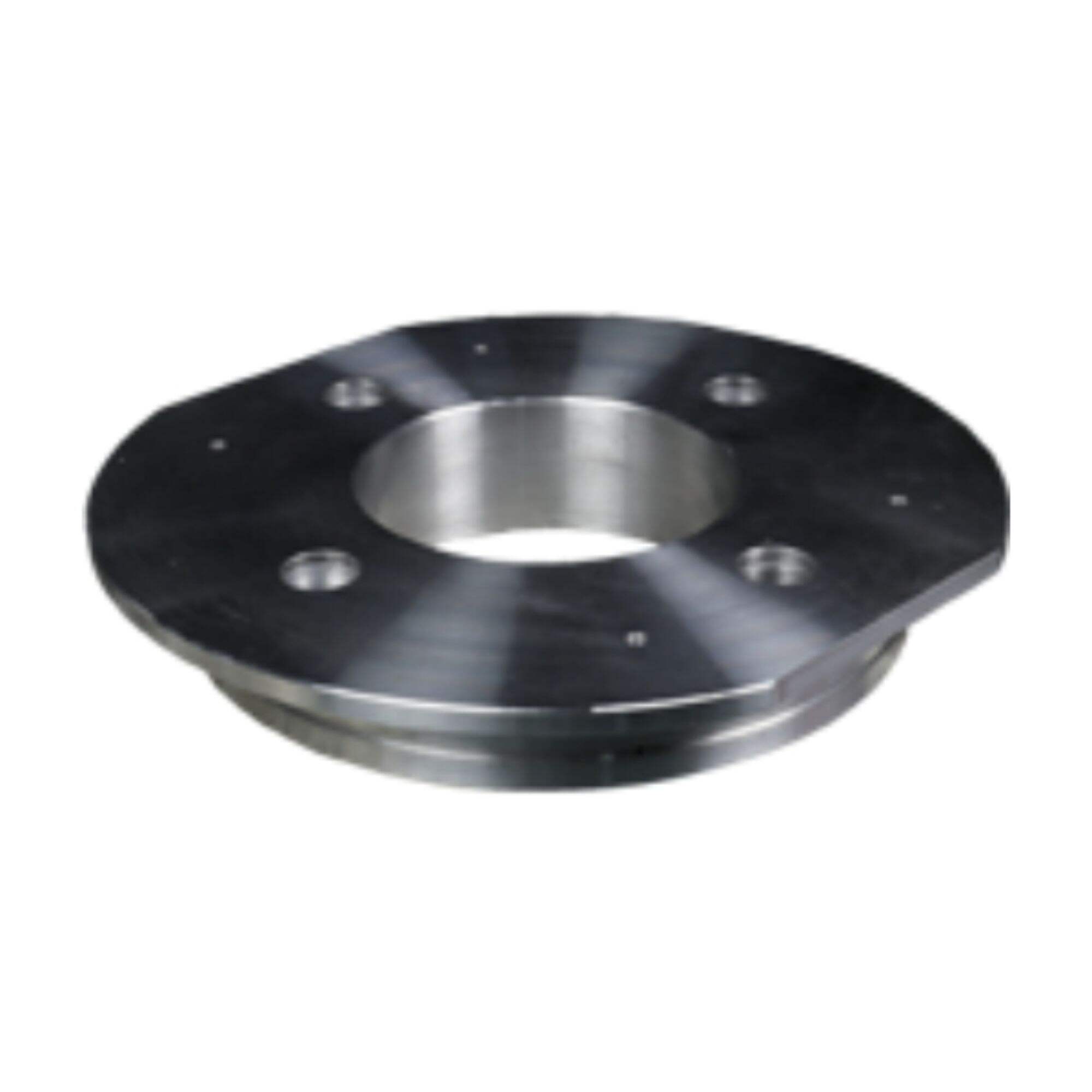

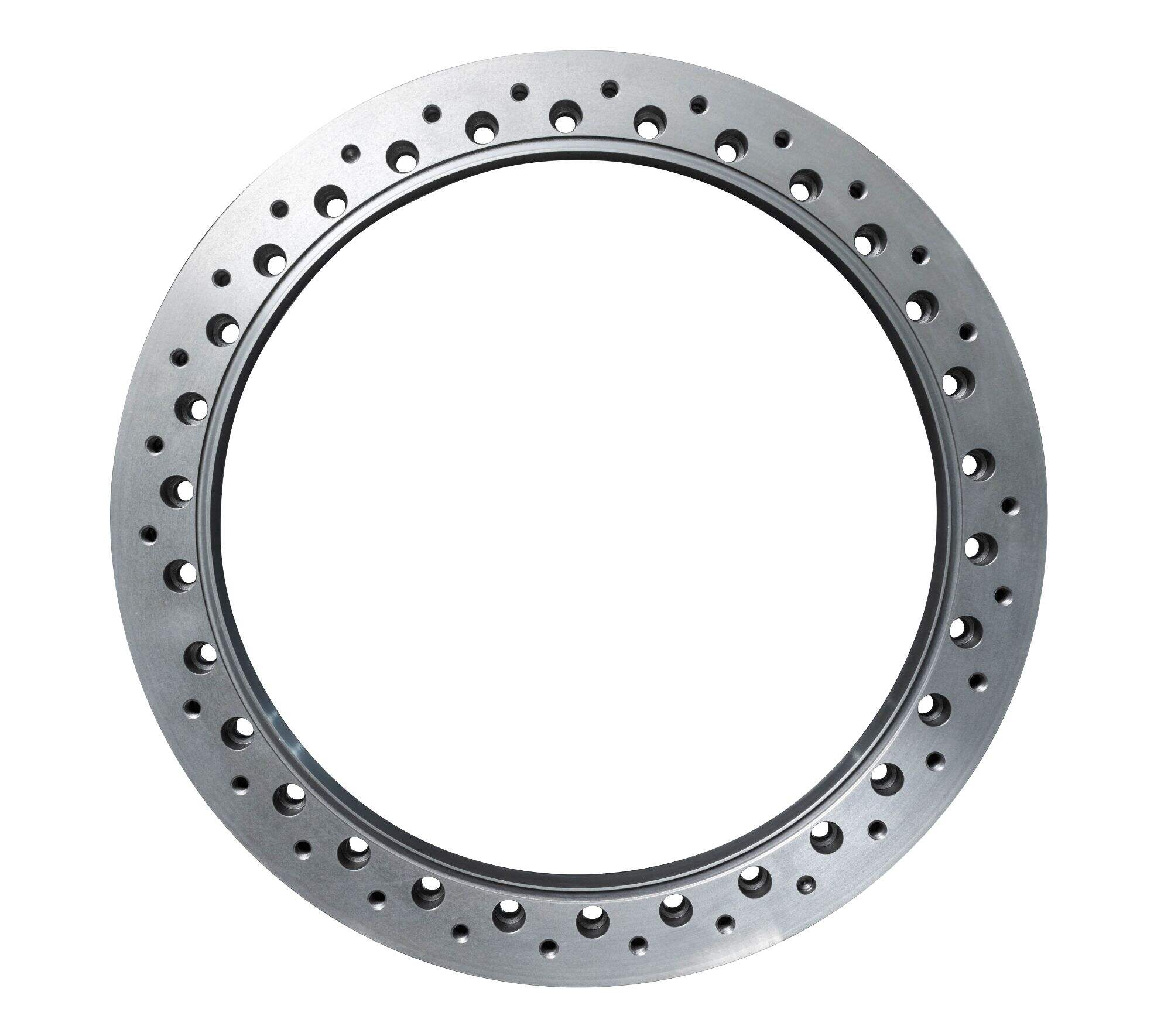

The other key part of the process is how we design the mold itself. The mold works as a unique container for the melted metal that gives it shape. You do need to be a little special about making it, so you know that the end result will turn exactly this awesome. This all takes time and skill, but it is so well worth to ensure a fine final product.

Using quality materials and creating tight molds helps to produce very accurate, strong parts. That is to say, they are only right when the jointed parts fit perfectly and we get a finished product exactly how it should be; hence income. It also means we can do more complexed forms and designs for what is possible not just making them well made, but in almost limitless configurations as new versions come about. Just think of all the incredible things we can create using great die casting!

Lastly, we will discuss the latest techniques and technology in premium die casting. These include vacuum die casting. The air from the mould has been expelled before pouring in of metal is done using this method. Why do we do this? It is necessary to avoid weak products in the absence of air pockets. Our monsters are meant to be heavy-hitting!

The other method is Hot chamber die casting. It is used for metals with lower melting temperatures like zinc. Here, hot metal is held in a heated chamber and then injected through pressure into the mold. This results in a part that is both robust and has a fine surface finish too. Think of a toy that feels nice and shiny to the touch!

Pingcheng currently has more than 20 manufacturing facilities and 50 highly skilled technical employees. They quality die casting. Mitsutoyo's measuring instruments and CMM are periodically calibrated. The double-checking keeps our quality steady and accurate. The machining and assembly of all key parts are tracked and controlled.

Pingcheng is quality die casting achieve their goals for business by providing our own supply chains and services solutions. We are focused on helping to extends the life and the values of your production. PingCheng could be the reliable supplier you requires. We are a trustworthy supplier who can offers you opportunities.

Pingcheng is a quality die casting and lifecycle partners. The shipping of our products is only the beginning of our partnerships. Our customer services is about ensuring your satisfaction. Since more than 20 years ago, we have offered manufacturing services and have built a closed collaboration with well-known Japanese firms. Pingcheng's dedications to fair pricing is based upon our years of experiences and understanding of this sector. We analyze the drawing in an advanced software program and then provides the most efficient solution at the most reasonable cost once we have received the requests for quotation.

Pingcheng's commitment for honest pricing is based on its years of experience in the industry and a deep understanding. We quality die casting, recreate it in specialized software, and then provide the most competitive price.