كيف تعمل طواحين الهواء وإنتاج الطاقة؟ هذا سؤال رائع! توربين الرياح هو نسخة ضخمة من المروحة التي تستخدم لتبريد نفسك في الطقس الحار. عندما تضرب الرياح شفرات التوربين، يجعلها ذلك تدور. الشفرات الدوارة متصلة بقطعة كبيرة تحمل اسمًا رائعًا يُسمى الروتر. ويرتبط هذا القرص بجهاز يُسمى صندوق التروس وهو المسؤول عن توليد الكهرباء.

المستوى هو مجرد صندوق يحتوي على العديد من العُدد بداخله. هذه العُدد بأحجام مختلفة وتتداخل لتحويل الحركة الدورانية الناتجة عن تأثير الرياح إلى كهرباء. بسبب ضرورة دوران التوربين عند السرعة والاتجاه المحددين بوضوح، فقط عندئذ يمكنه إنتاج الكهرباء. وهذا بدوره يسمح لأن works بشكل فعال وإنتاج الكهرباء مع مساعدة من المستوى الذي يدعم الحركة.

ولكن كيف يعمل صندوق التروس فعليًا؟ هنا يمكننا توضيح تلك الفكرة الخاطئة! يوجد العديد من التروس داخل صندوق التروس والتي لديها أقطار متفاوتة. هذه تروس بأحجام مختلفة، كبيرة وصغيرة جدًا. بينما يدور المولد الكهربائي، فإن التروس الداخلية تدور أيضًا - تمامًا كما يحدث مع نظام تبديل التروس العادي. يتم تحكم وتغيير دوران المولد الكهربائي السريع إلى سرعة دوران أبطأ بواسطة التوربينات المتصلة في مراحل أخرى لتحويلها إلى طاقة كهربائية.

يقوم صندوق التروس دائمًا بنقل القوة من خلال واحدة على الأقل من التروس. وهذا لأنها تدور باستمرار وتتعاون مع بعضها البعض لضمان أن المولد الكهربائي والمحرك يدوران بسرعة مناسبة. في الممارسة العملية، يضمن صندوق التروس أيضًا أن المولد الكهربائي يستمر في الدوران حتى عندما تكون الرياح ضعيفة. وبسبب ذلك، يمكن للتوربين إنتاج الكهرباء بشكل مستمر بغض النظر عن ظروف الرياح.

تُجهَّز توربينات الرياح بتقنيات متقدمة بشكل متزايد، وهذا هو الحال أيضًا في صناديق التروس الخاصة بها. على سبيل المثال، في الماضي كانت توربينات الرياح تحتوي على صندوق تروس واحد مع مجموعة واحدة من التروس. ومع ذلك، فإن معظم التوربينات الحديثة تستخدم نظامًا أكثر تعقيدًا يُعرف بصندوق التروس الكوكبي. يُسمى هذا التكوين بأنه صندوق تروس يحتوي على ثلاث مجموعات من التروس تعمل معًا لتسهيل حركة كل شيء بسلاسة وكفاءة.

ميزة خاصة لصندوق التروس الكوكبي هي نظام الزاوية. يقوم نظام الزاوية بتغيير زاوية الشفرات وفقًا لسرعة الرياح. على سبيل المثال، إذا كانت الرياح قوية جدًا، فستدور الشفرات بشكل طفيف؛ بهذه الطريقة تكون أقل انحدارًا ولا تدور بسرعة كبيرة. وعلى العكس، عندما تكون هناك رياح خفيفة فقط، يمكن لنظام الزاوية أن يميل الشفرات أكثر لتمكين إنتاج الطاقة حتى في أوقات سرعات الرياح المنخفضة.

تتوفر المراوح بجميع الأحجام، تمامًا مثل توربينات الرياح. لا تستخدم توربينات الرياح الصغيرة، مثل تلك المستخدمة في المنازل والمدارس، أي صناديق تروس بناءً على حقيقة أنها تحتوي على عدد محدود من الشفرات. قد تتجاوز التوربينات المصغرة صندوق التروس، لكن بالتأكيد لا يمكنها العمل بدونه في التوربينات الكبيرة التي تزوّد المدن والقرى بالطاقة. يقوم بذلك لضمان أن كل شيء يتحرك بمعدل صحيح، مما يساعد في إنتاج الكهرباء بكفاءة.

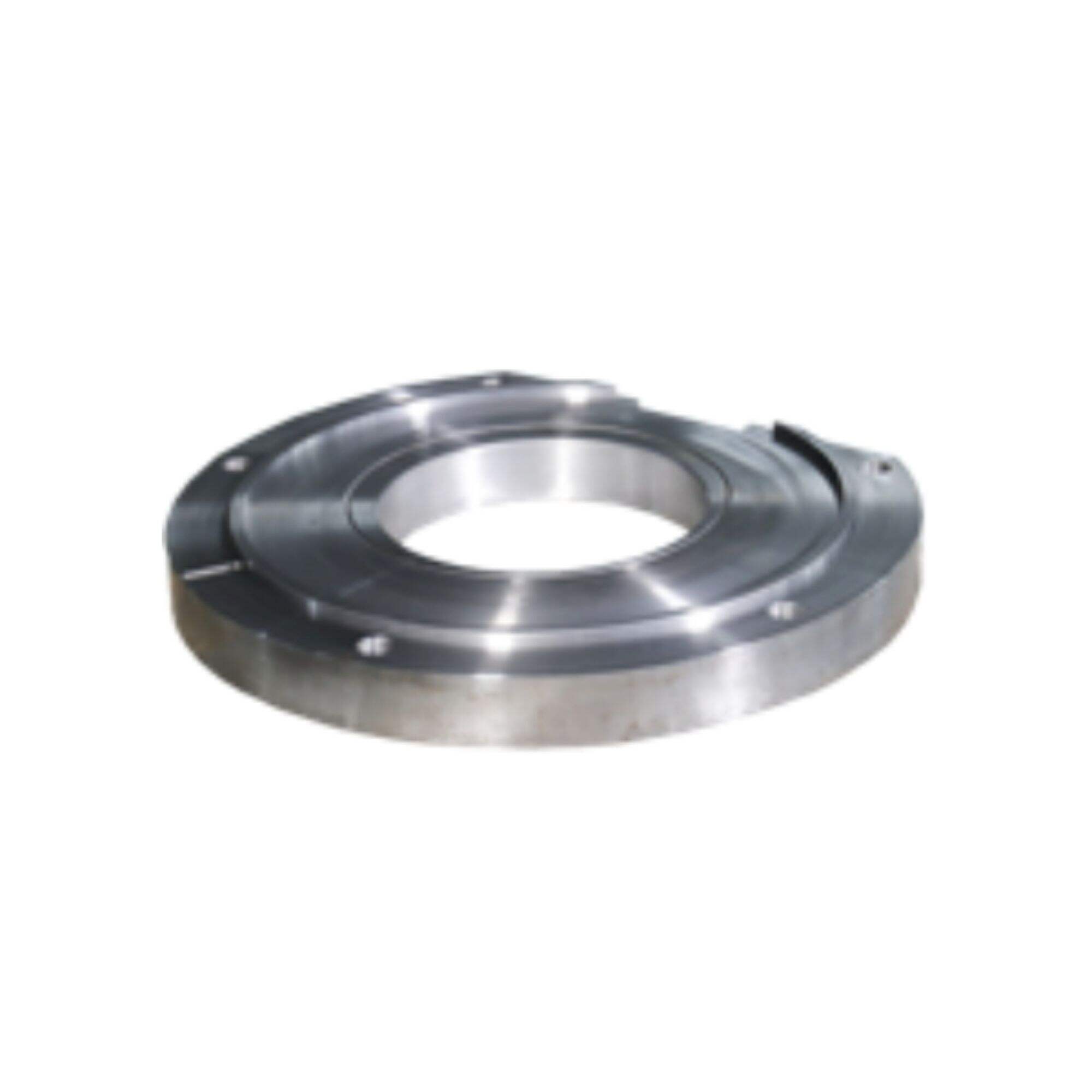

تمتلك شركة بينغتشنغ حاليًّا أكثر من ٢٠ قطعة معدات تصنيع ومجموعة تروس مستخدمة في توربينات الرياح. وهي تسعى لتقديم منتجات عالية الجودة. وتتم معايرة أجهزة القياس الخاصة بشركة ميتسوتويو وأجهزة قياس الإحداثيات (CMM) بشكل دوري. ويضمن هذا التحقق المزدوج أن تكون جودة منتجاتنا موثوقةً ودقيقةً. كما يمكن تتبع جميع الأجزاء الرئيسية ورصدها أثناء عمليات التشغيل الآلي والتركيب.

وبناءً على عقود من الخبرة في مجال مجموعات التروس المستخدمة في توربينات الرياح، تلتزم شركة بينغتشنغ بتقديم أسعار عادلة لعملائها. فنحن ندرس الرسومات الفنية، ثم نُنشئ النموذج باستخدام برامج متخصصة، وبعد ذلك نقدّم لك أفضل سعر ممكن.

بينغتشنغ هو علبة تروس تُستخدم في توربينات الرياح وشركاء دورة الحياة. إن شحن منتجاتنا ليس سوى بداية لشراكاتنا. وخدمات العملاء لدينا تهدف إلى ضمان رضاكم التام. ومنذ أكثر من 20 عامًا، قدّمنا خدمات التصنيع وبنينا تعاونًا متكاملاً مع شركات يابانية معروفة عالميًّا. وتستند التزامات بينغتشنغ بالأسعار العادلة إلى خبرتها الطويلة وفهمها العميق لهذا القطاع. فنحن نحلّل الرسومات باستخدام برنامج متقدم ثم نقدّم الحلَّ الأمثل بأقل تكلفة معقولة بمجرد استلام طلبات الاقتباس.

تم تصميم علب تروس بينغتشنغ المستخدمة في توربينات الرياح والخدمات المرتبطة بها لمساعدة العملاء على تحقيق أهدافهم التجارية. ونحن نركّز على توسيع إمكانات إنتاجكم وزيادة عمره الافتراضي. وتعتبر شركة بينغتشنغ منتجًا موثوقًا به تبحثون عنه. ونحن مورِّدون يوفرون الفرص.